Sharpening & Grinding

Sharpening your tools is an essential part of a woodworker’s job!

Don’t see it as a necessary evil!

Dry or wet grinding?

Do not use a dry grinding machine to sharpen your quality chisels and plane irons made from carbon steel. The heat generated leads to a loss of hardness, significantly reducing the tool’s life. It is a common misconception that this doesn’t happen if you just remove the iron from the fast-rotating grinding wheel in time before it turns blue and dip it in water. Structural changes occur at much lower temperatures. You cannot control this process. Complaints about seemingly poor steel quality in irons, whose good quality I was aware of, were always due to treatment with dry grinding machines. Slow-running wet grinders (approximately 90 to 120 revolutions per minute) prevent heat buildup. They grind slower than dry grinders, but they ensure good treatment of your tools. The best available on the market are based on a sophisticated system and are manufactured by TORMEK in Sweden. However, the purchase costs exceed many budgets.

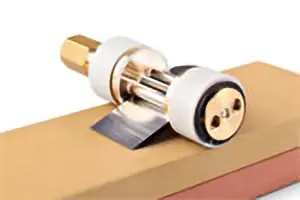

With good sharpening stones, a grinding guide, and some practice, you will achieve the best results. When sharpening by hand, you get to know your tool best, and you are independent of the usually stationary machine. Moreover, a grinding machine is of no use to you when you want to dress the flat side of your plane iron. For that, you need a flat surface that a round-running machine cannot provide.

There are differing opinions on whether the bevel of an iron should be better hollow-ground, as with machine grinding, or better straight as with hand sharpening on the sharpening stone. Hollow grinding makes subsequent honing easier, but the resulting sharper angle weakens the edge and makes it more prone to chipping. This is particularly negative for the very hard laminated Japanese irons. In Japan, it is unthinkable to hollow-grind the bevel of a plane iron. E.C.E.'s grinding recommendation for plane irons is clear against hollow grinding. If you choose a straight bevel for your plane irons or chisels, you are in good company.

Waterstone or oilstone?

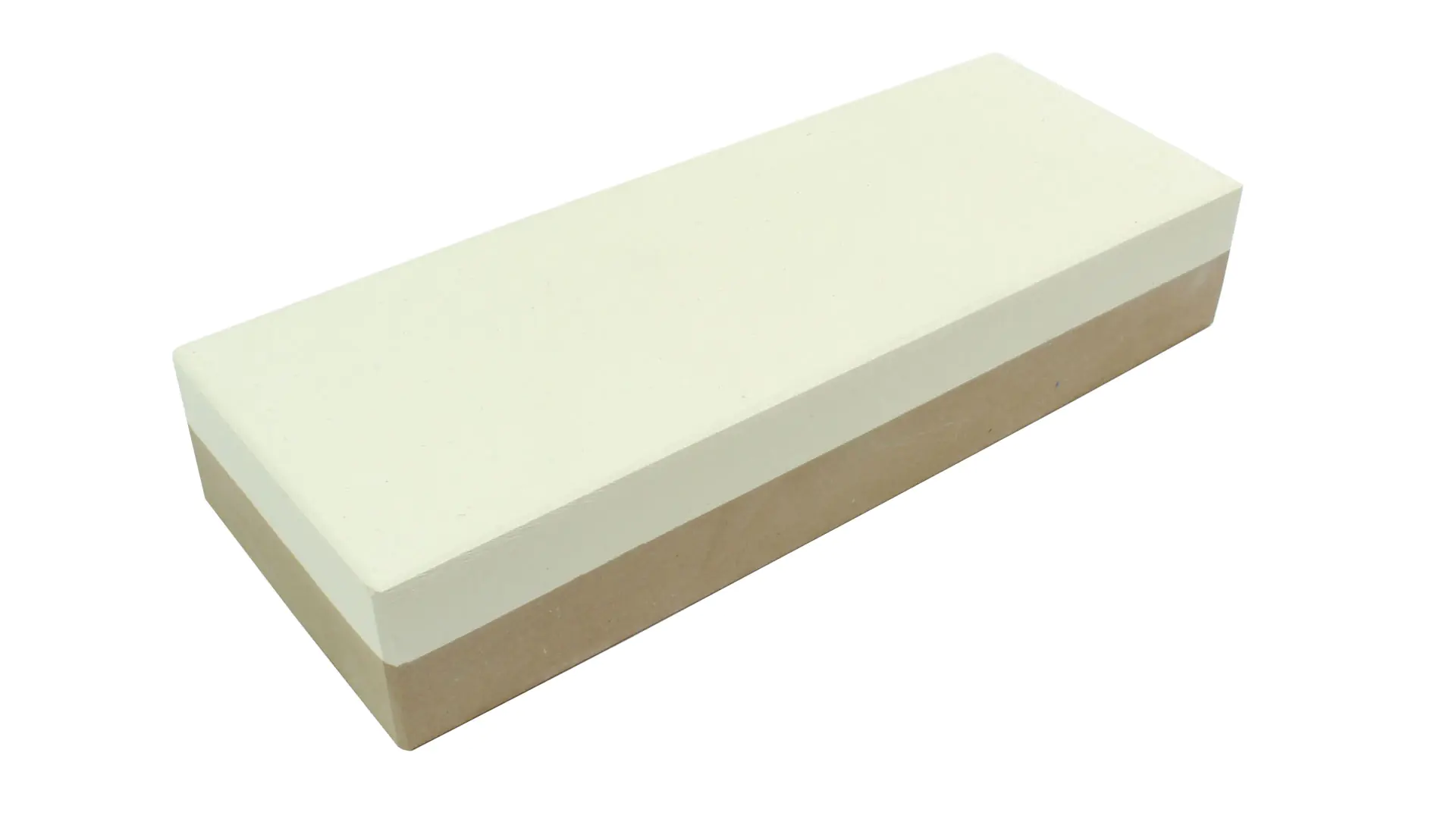

Many stones work effectively with both water and oil. However, once a stone has been used with oil, it cannot be used with water anymore. The mineral oil used is not particularly healthy on the skin, which is why I prefer waterstones. Due to their superior qualities, Japanese waterstones are becoming increasingly popular.

The soft Japanese waterstones should only be used with water. They allow for effective sharpening because their loose bonding constantly releases new abrasive particles. It suffices to submerge them in water for five to ten minutes before sharpening. It is less advisable to leave them in water continuously, as a greasy layer forms on the surface, or in some cases, the surface disintegrates.

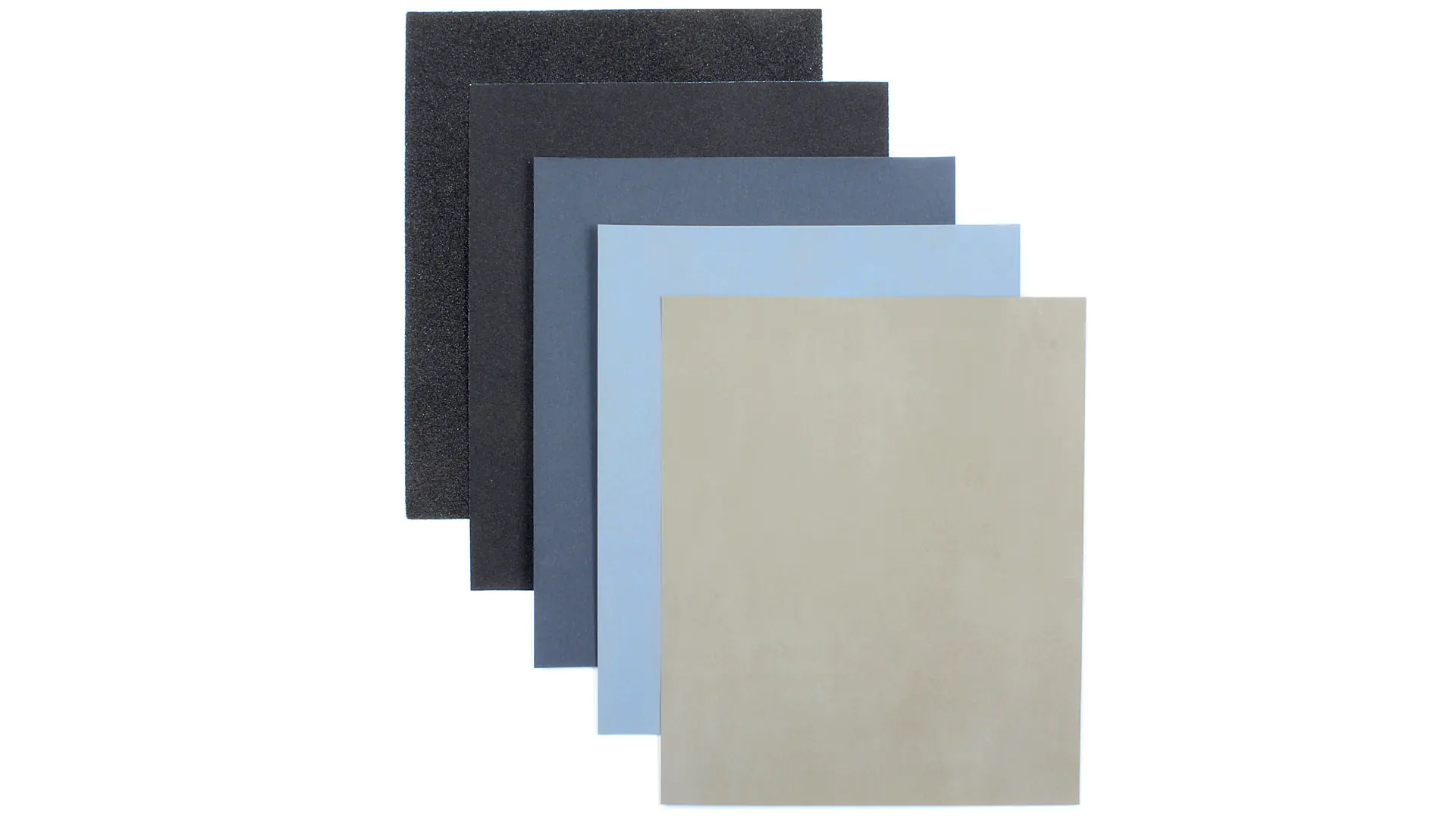

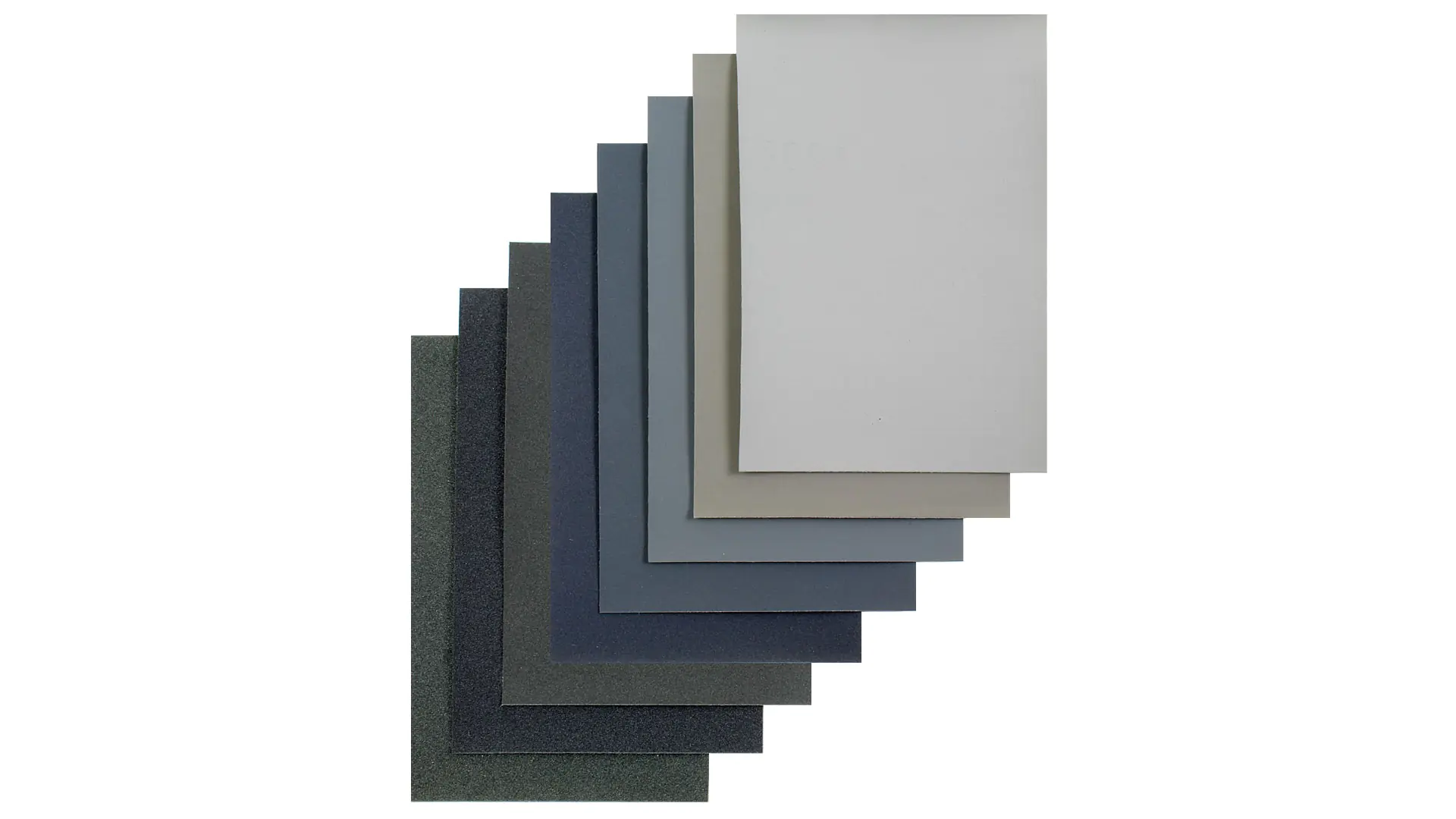

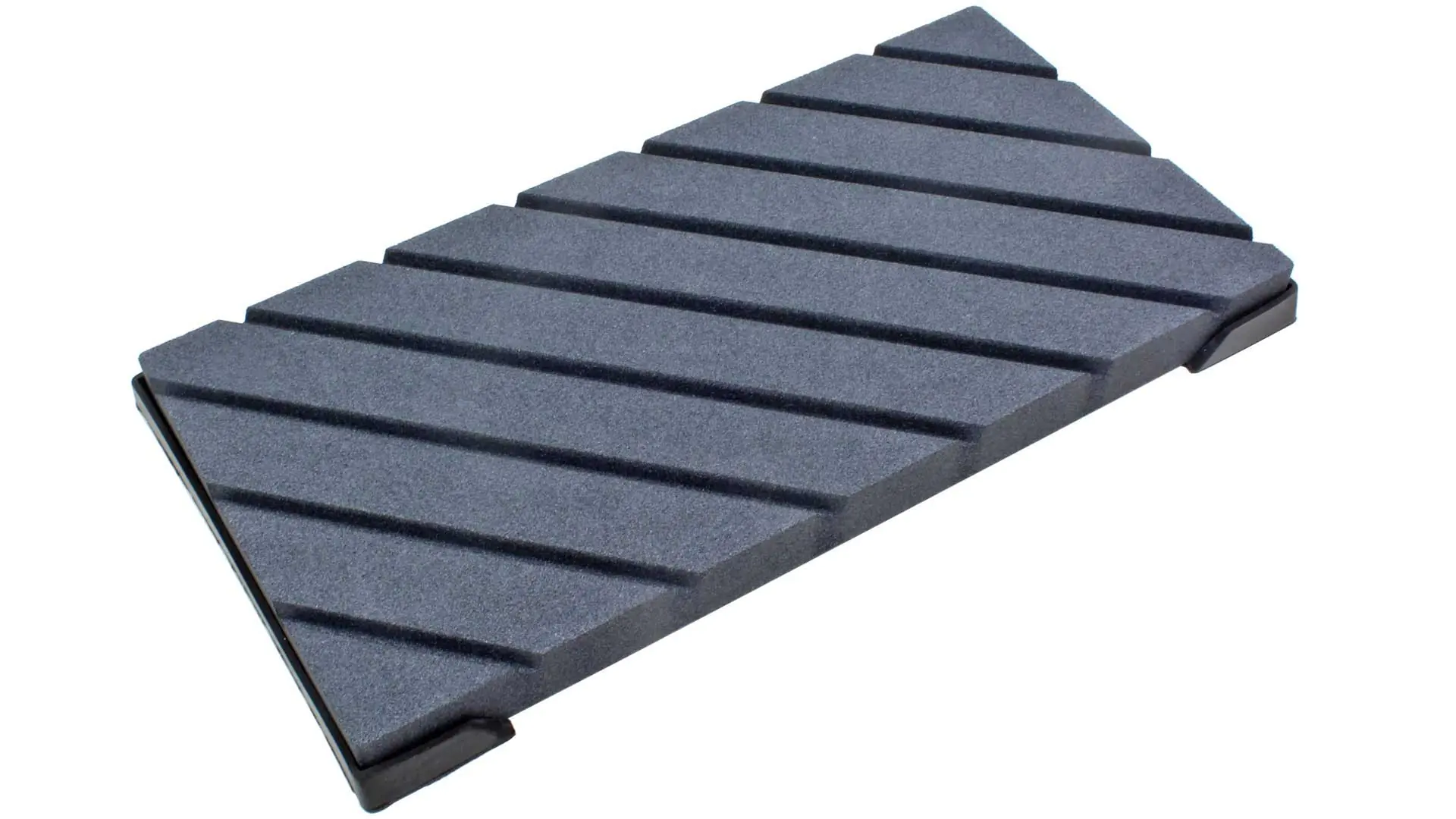

These stones, however, hollow out faster than hard stones and need to be re-dressed regularly. This is quickly done using the following method: You need waterproof sandpaper grit 80 and finer, a smooth surface as a base, preferably a glass plate, and – if you want it even faster – a tin of silicon carbide powder. A puddle of water on the glass plate to hold the sandpaper in place, a bit more water, and a teaspoon of silicon carbide powder on the paper, move the stone with little pressure – and within a few minutes, it is perfectly dressed.

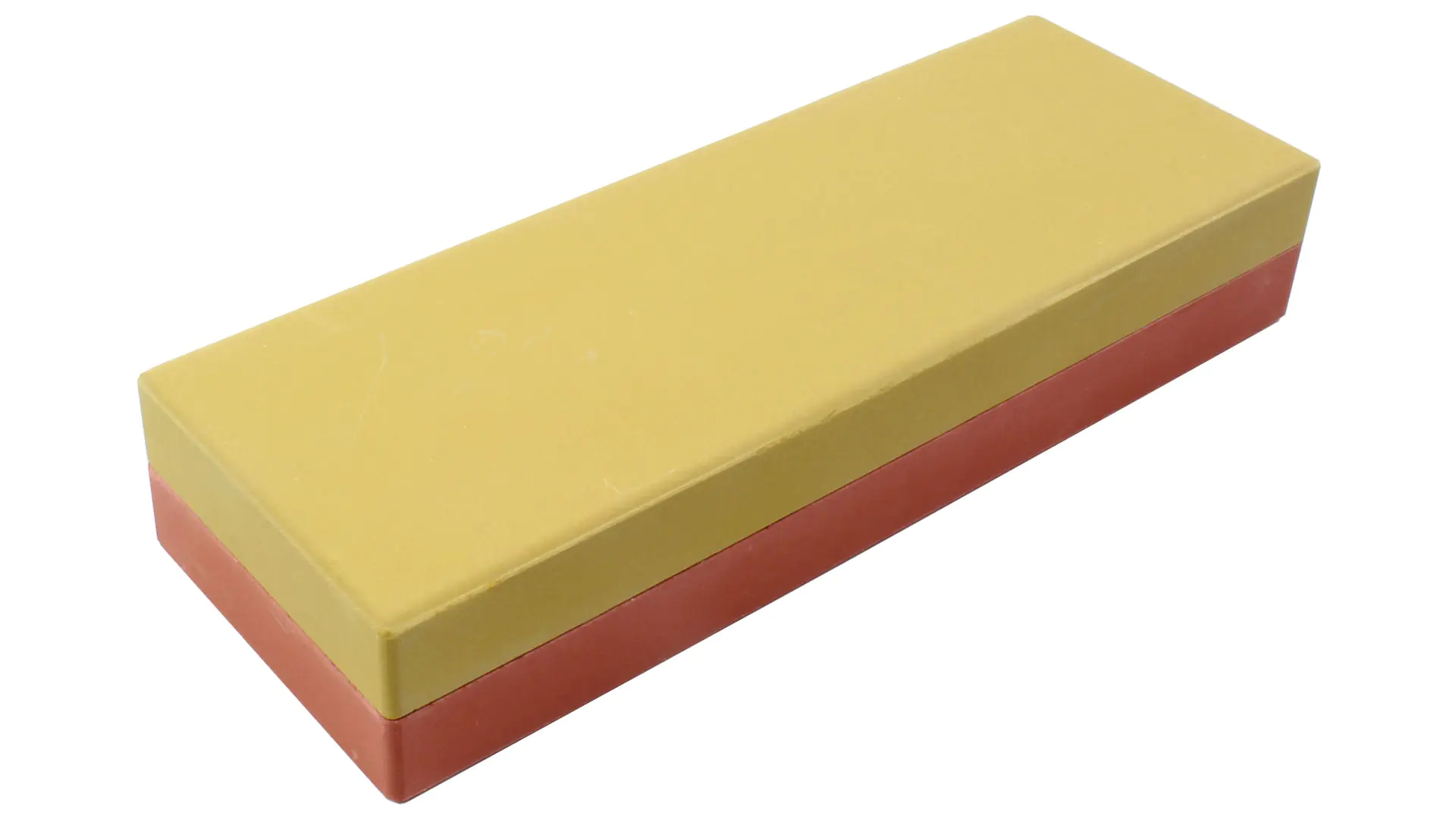

As basic equipment, it is recommended: a sharpening stone with grit 700 – 1200, a honing stone with grit 3000 – 6000, a grinding guide. As an addition, a coarse stone with grit 120 – 400 is recommended. If plane irons are also sharpened with the grinding guide, the stone should be a few millimeters wider than the widest iron. Sharpening and honing stones are also available as combination stones.

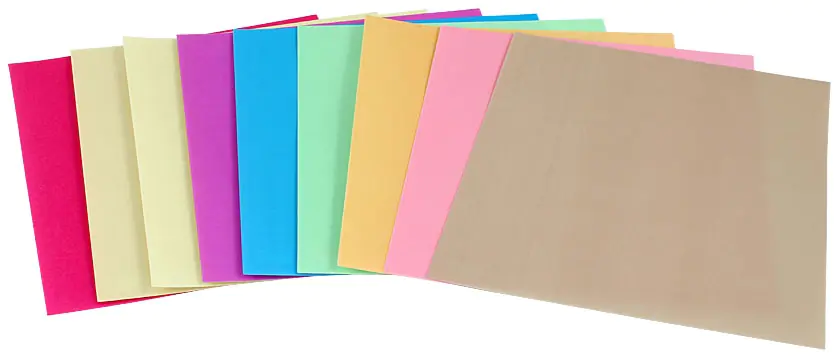

It is known that many stainless steels, especially stainless steel knives, are very difficult to sharpen. Even Japanese waterstones sometimes reach their limits and clog up. Which, incidentally, is not a problem, as described in the method above for dressing, they are quickly cleaned again. If you have such knives or chisels, a visit to the Missarka artificial stones may be worthwhile.

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available in 36 days, delivery time 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany