Pocket Mill Pro with Angle

JESSEM

Available, delivery time: 1-3 businessdays within Germany

Product information

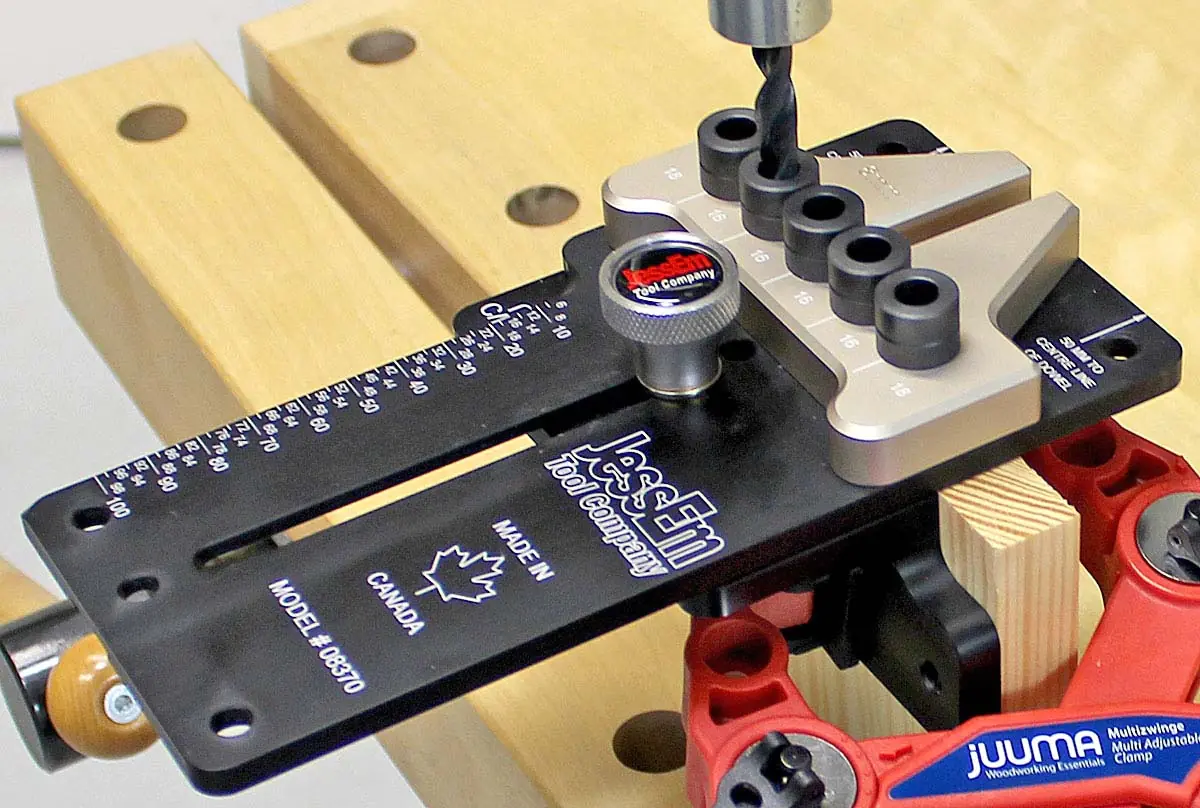

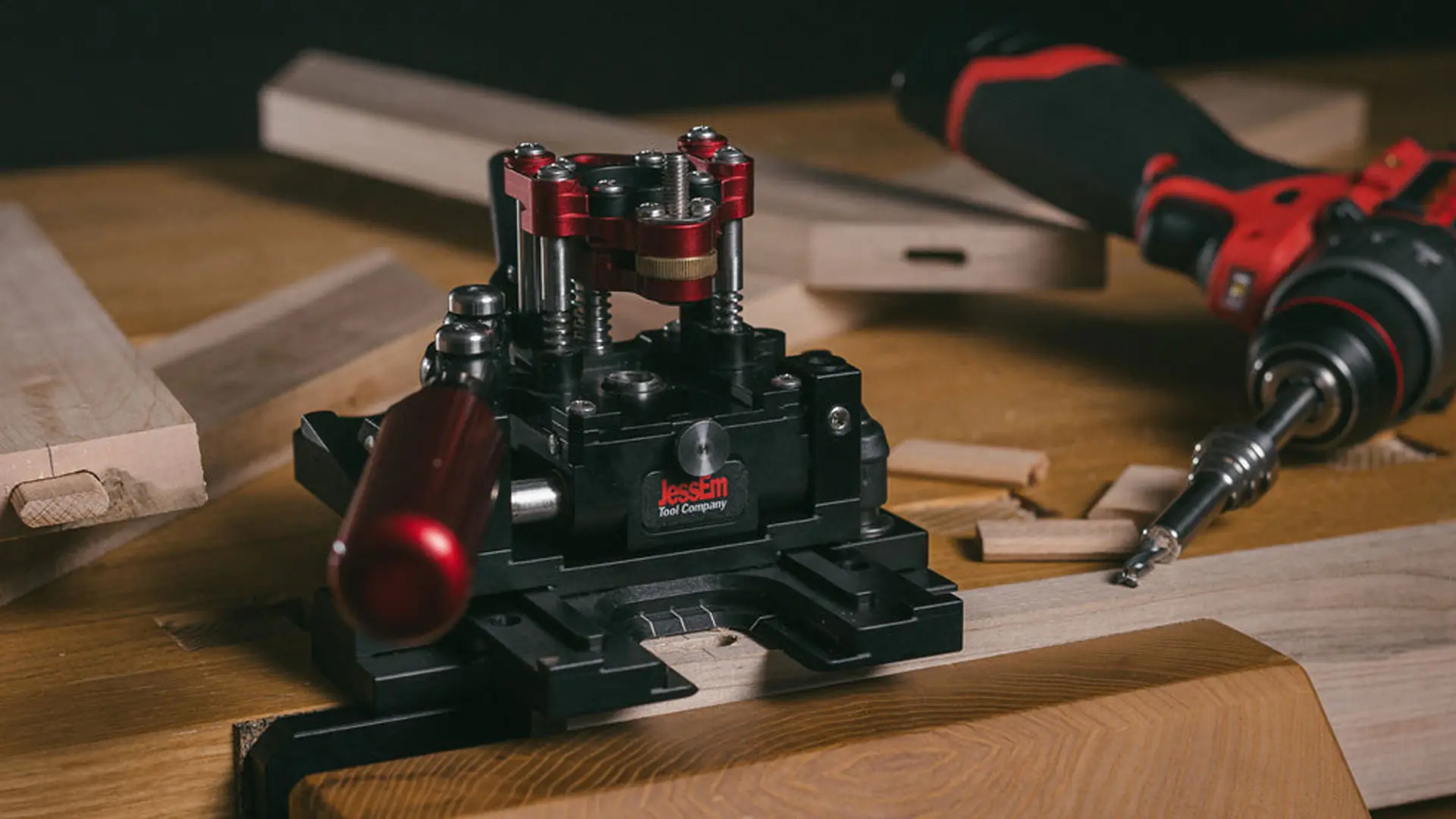

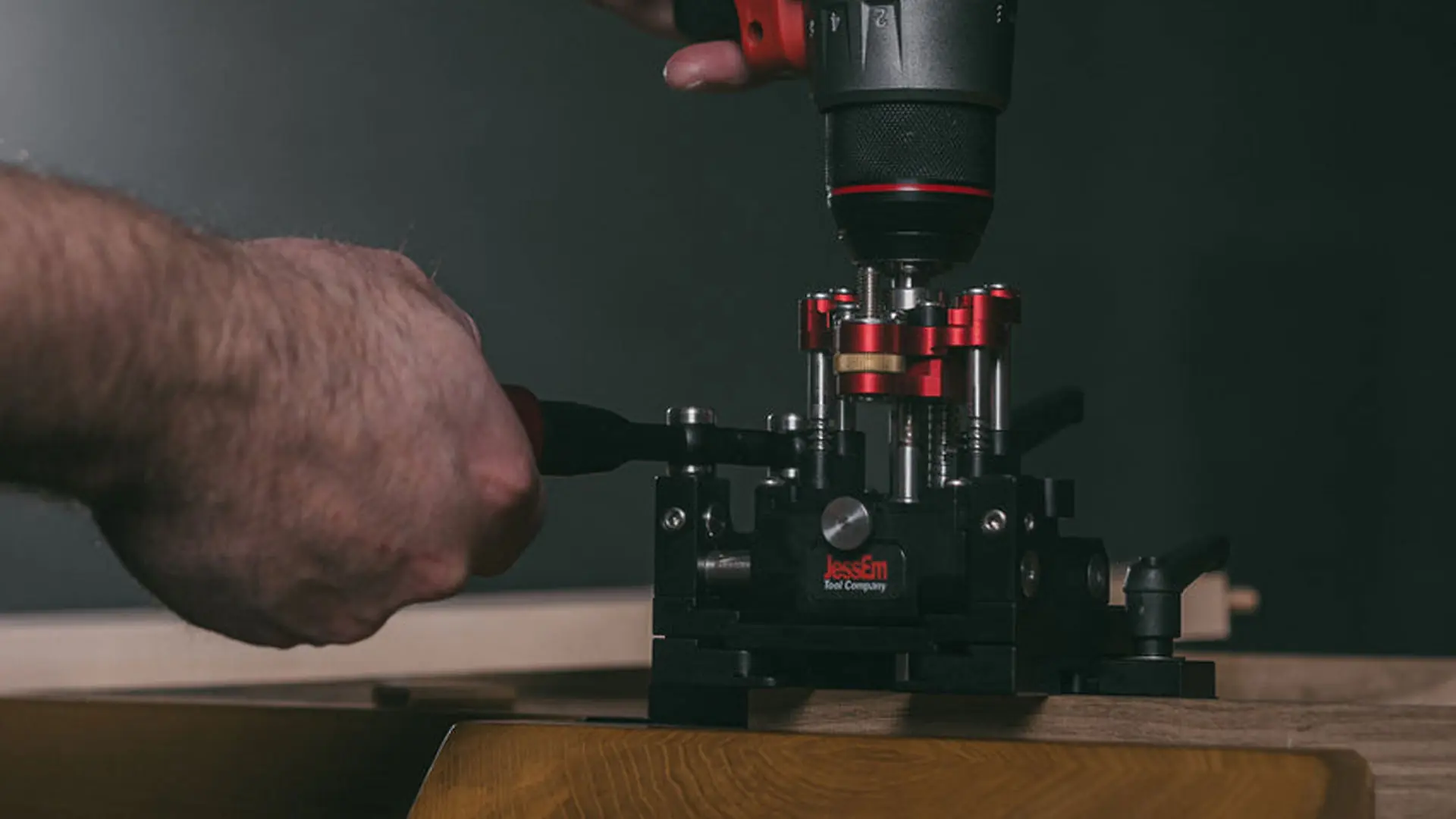

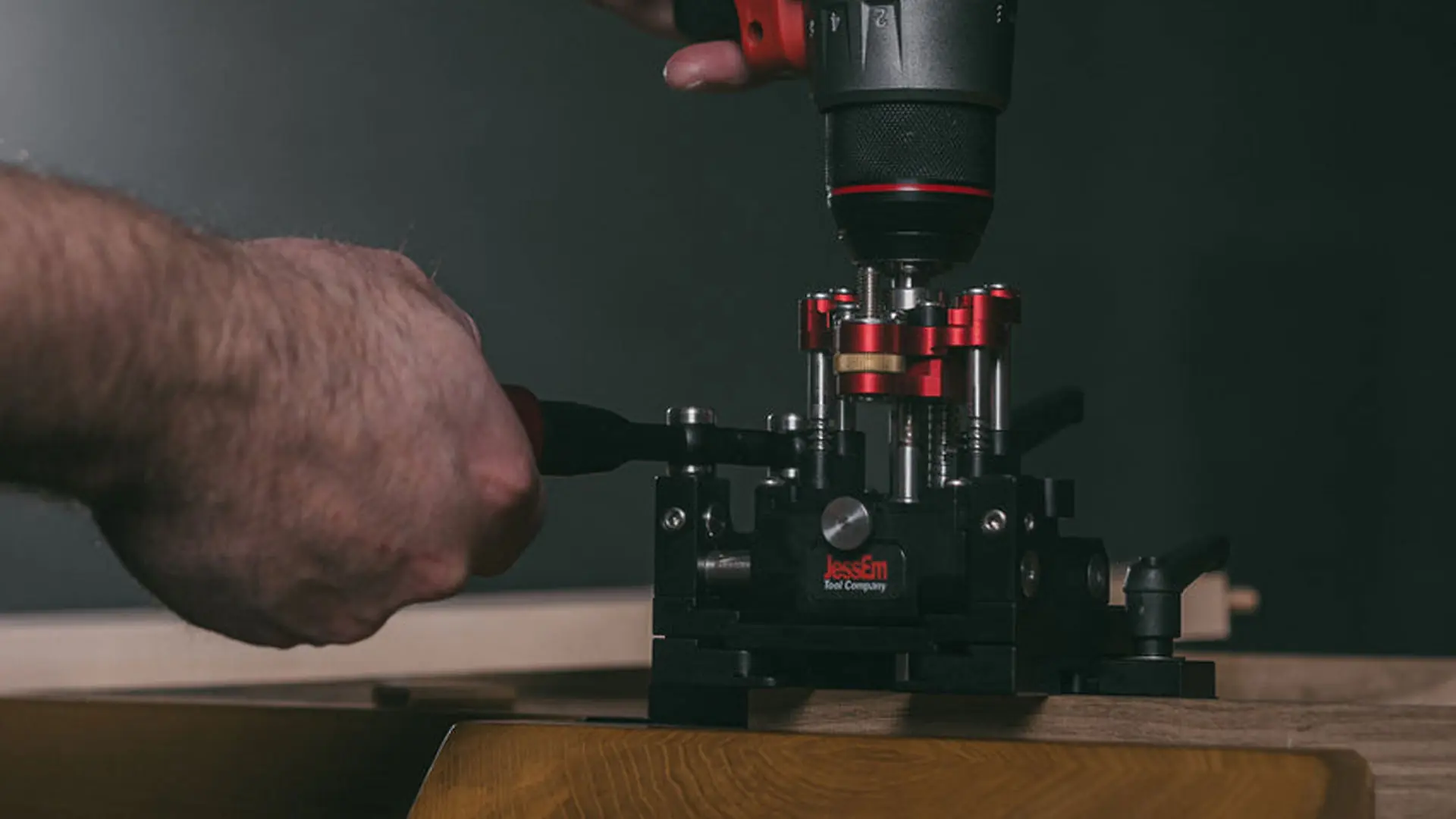

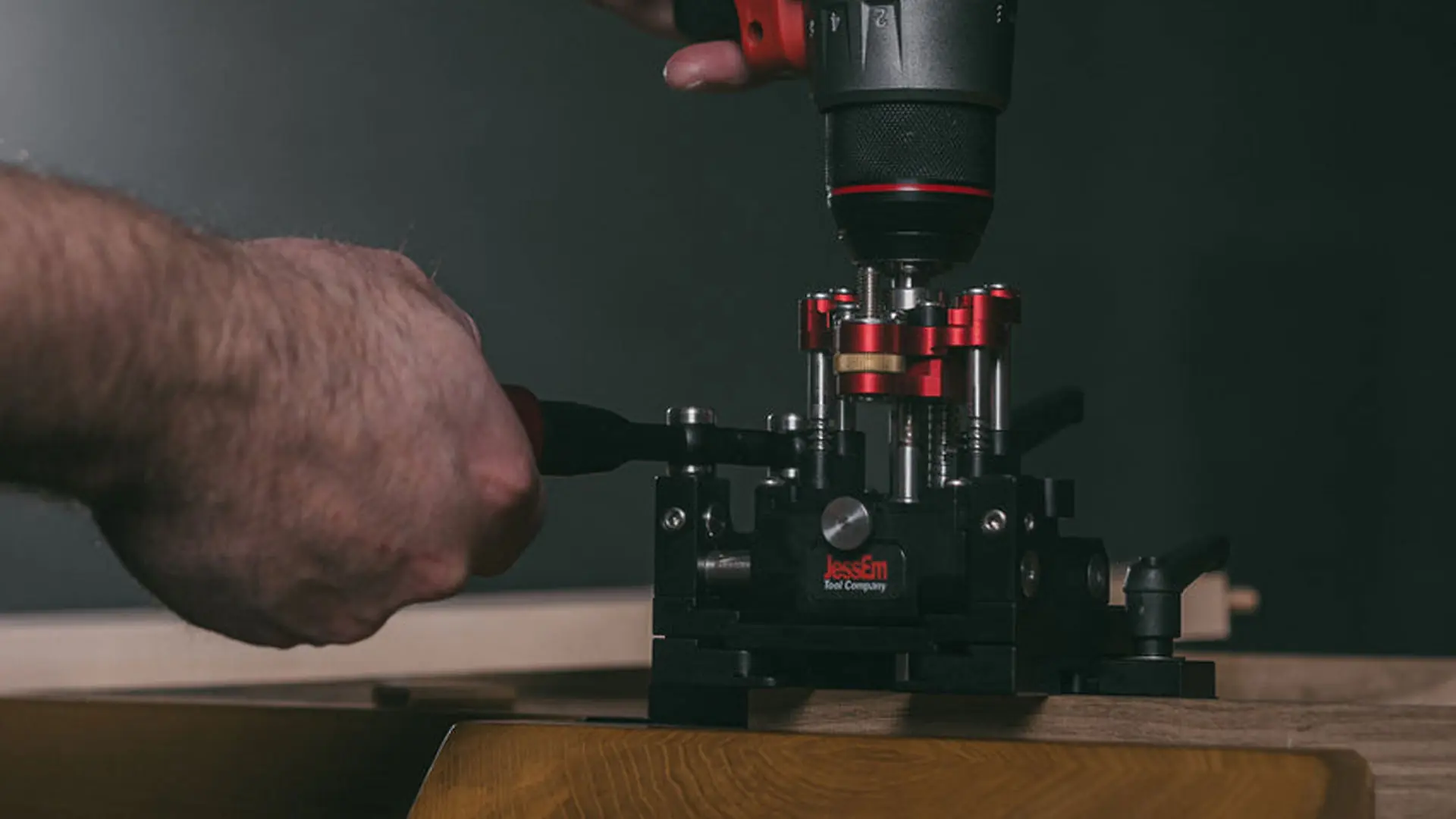

The angle can be attached to a workbench or a jointer bench using screws (not included). Two clamping screws, with adjustable clamping levers, secure the movable carriage, which has the necessary markings for precise positioning of the workpiece to be processed. Once the piece of wood is secured, for example, using clamps, toggle clamps, or a front vise, the main body is moved toward the workpiece until it reaches the stop and is secured in the working position with the large central clamping lever. The width of the insertion hole is determined by lateral set screws with Allen key sockets, allowing for a tighter or looser fit as desired. The desired depth is set with the easy-to-use knurled nut at the front. One full rotation corresponds to 1 mm, and one detent, a clearly audible and tactile „click,” represents a 0.13 mm adjustment.

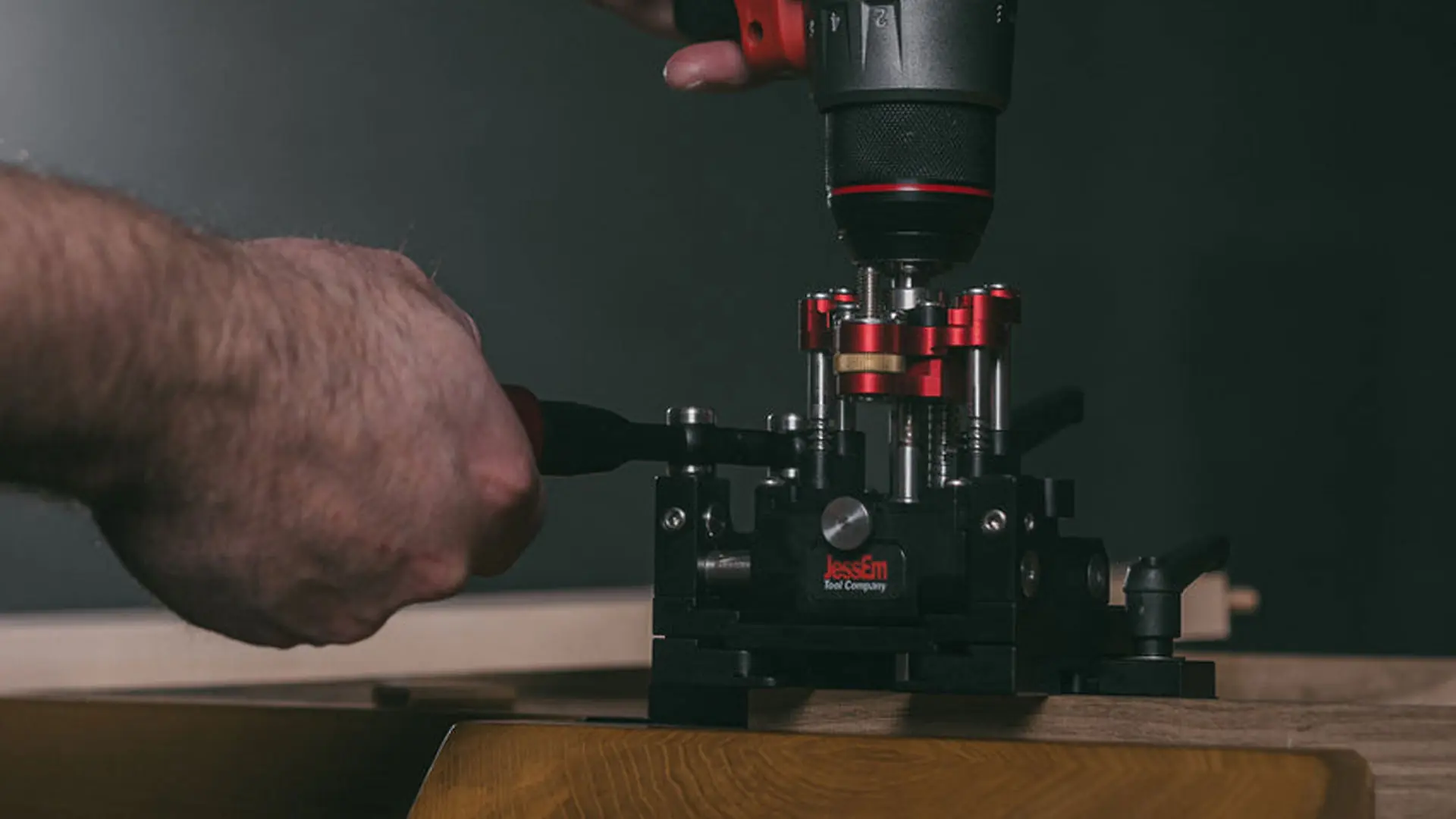

Now, all that is needed is to secure the milling drill (Endmill Kit) in a drill or cordless screwdriver and insert it into the drill bushing. With vertical pressure and simultaneous lateral movement of the guide lever on the left side, continuing each time until the set stops on the right and left, the process is repeated until the set depth is reached and no further progress can be made. After each pass from left to right, the template automatically lowers by about 1.3 mm. The handling does not require great coordination skills from the user but comes almost naturally. A press on the central front button releases the mechanism and brings the unit back up to the starting position.

Scope of delivery:

- Mounting angle made of anodized, 11 mm thick aluminum

- Carriage made of anodized aluminum

- Main body made of anodized aluminum, stainless steel, and brass, clamping lever made of plastic, Allen key for lateral limiting screws

- 2 extraction nozzles made of plastic, positionable to the left or right, inner/outer diameter: 1x 31.5/38 mm, 1x 35/40 mm

- Milling Drill Endmill Kit 6 mm (Article 332097)

Pocket Mill Pro by JessEm in General

For joining components at corners, whether butt joints or miter joints, but also on surfaces, both for solid wood and prefabricated panel material, round dowels have long proven effective.

Unlike the later-developed flat dowels in various versions, the financial investment for round dowels remains limited. With a dowel template, you’re ready to go; a drill or cordless screwdriver should be available in any workshop.

For the use of a flat dowel system, however, high-priced special machines were previously required, which typically only pay off when used regularly and extensively. So primarily in professional applications where speed and quantity matter.

The Canadian manufacturer JessEm, known for innovative and thoughtful solutions in woodworking for a long time, has now introduced a kind of hybrid solution that allows the use of flat dowels with a minimum of additional required tools or additional costs.

The patent-pending Pocket Mill Pro is particularly interesting for semi-professional users but can also be used in smaller professional workshops where the highest throughput is not decisive, and for less experienced DIY beginners who want to make the cost-effective step to a higher level.

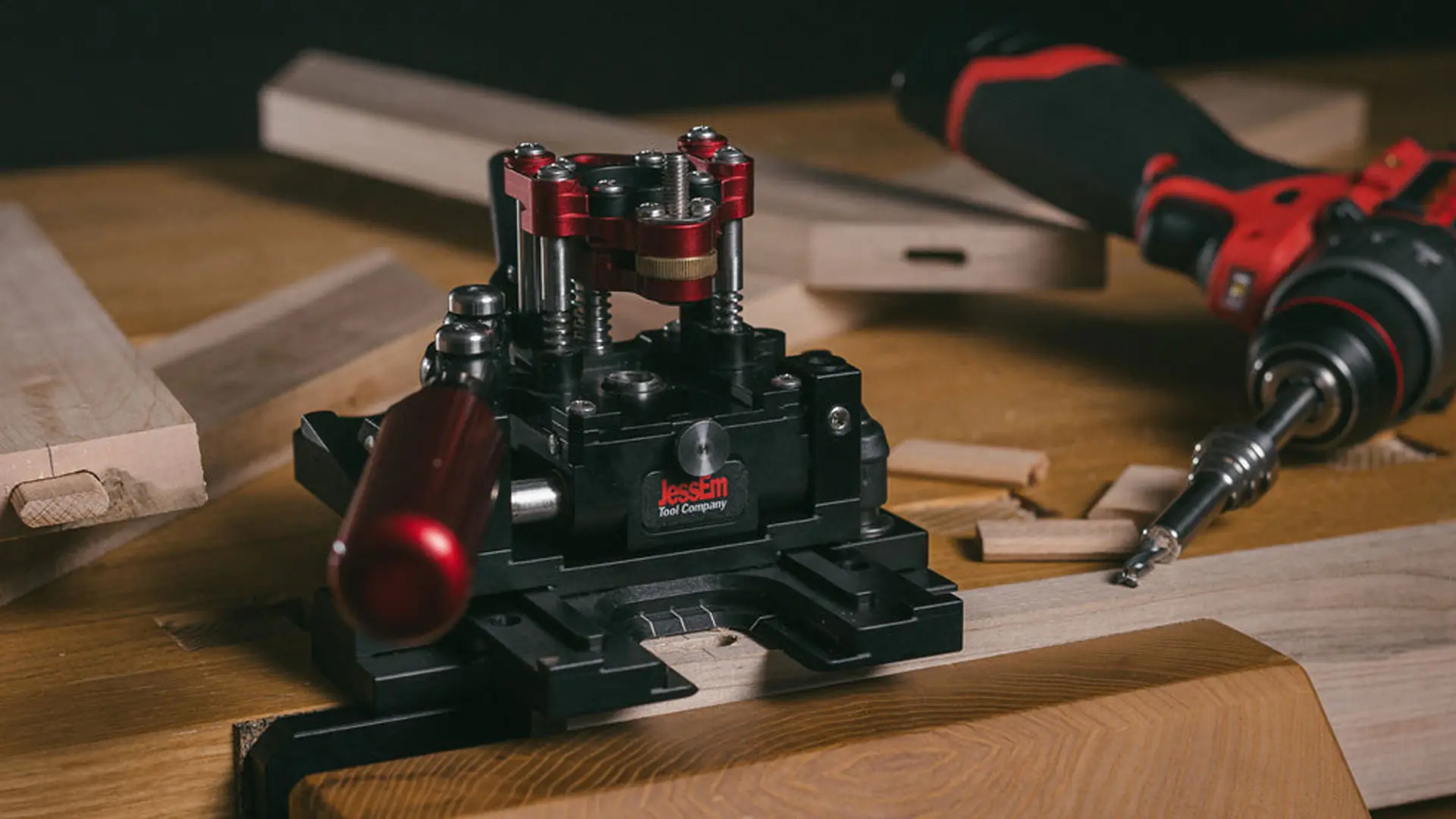

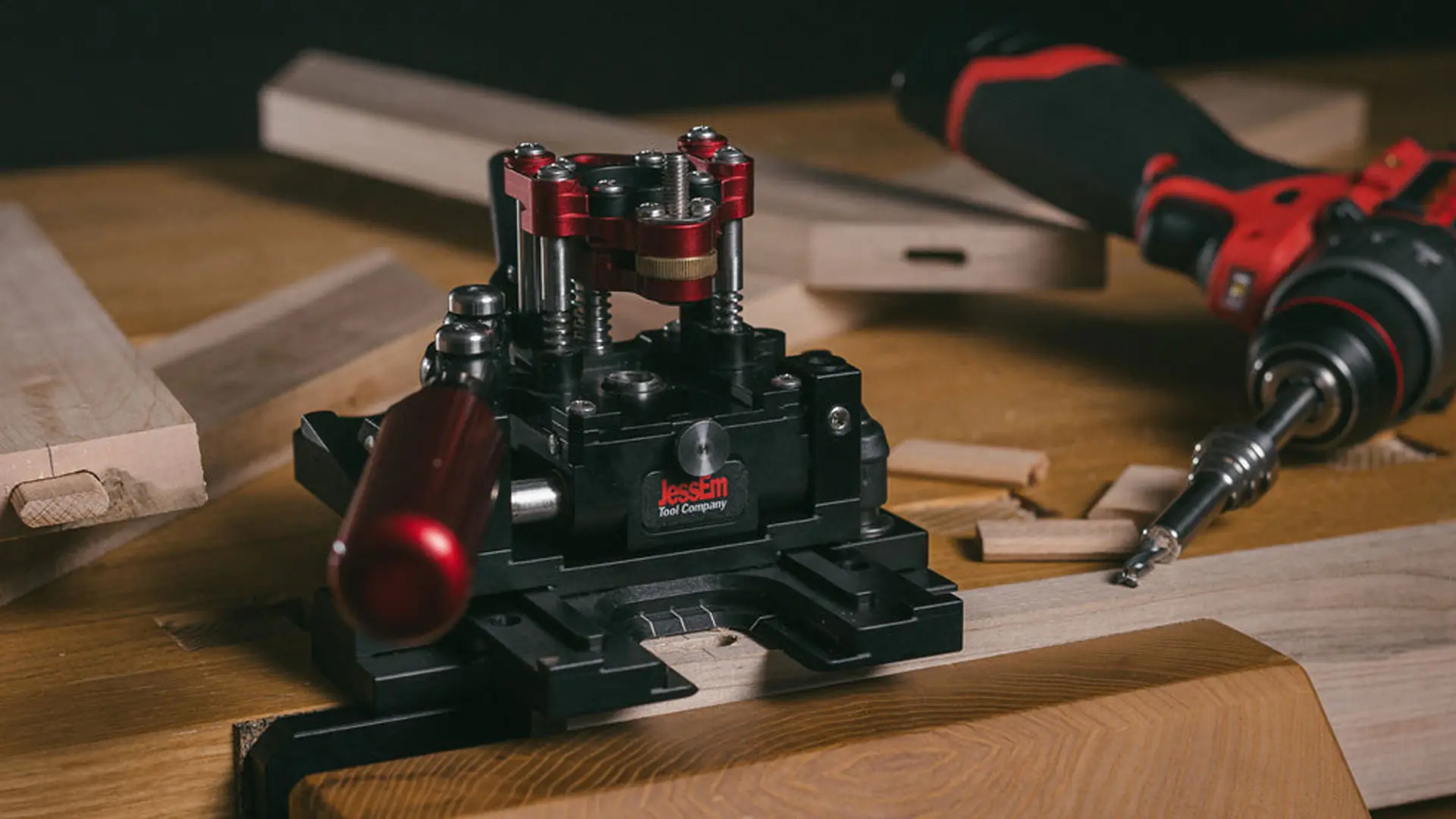

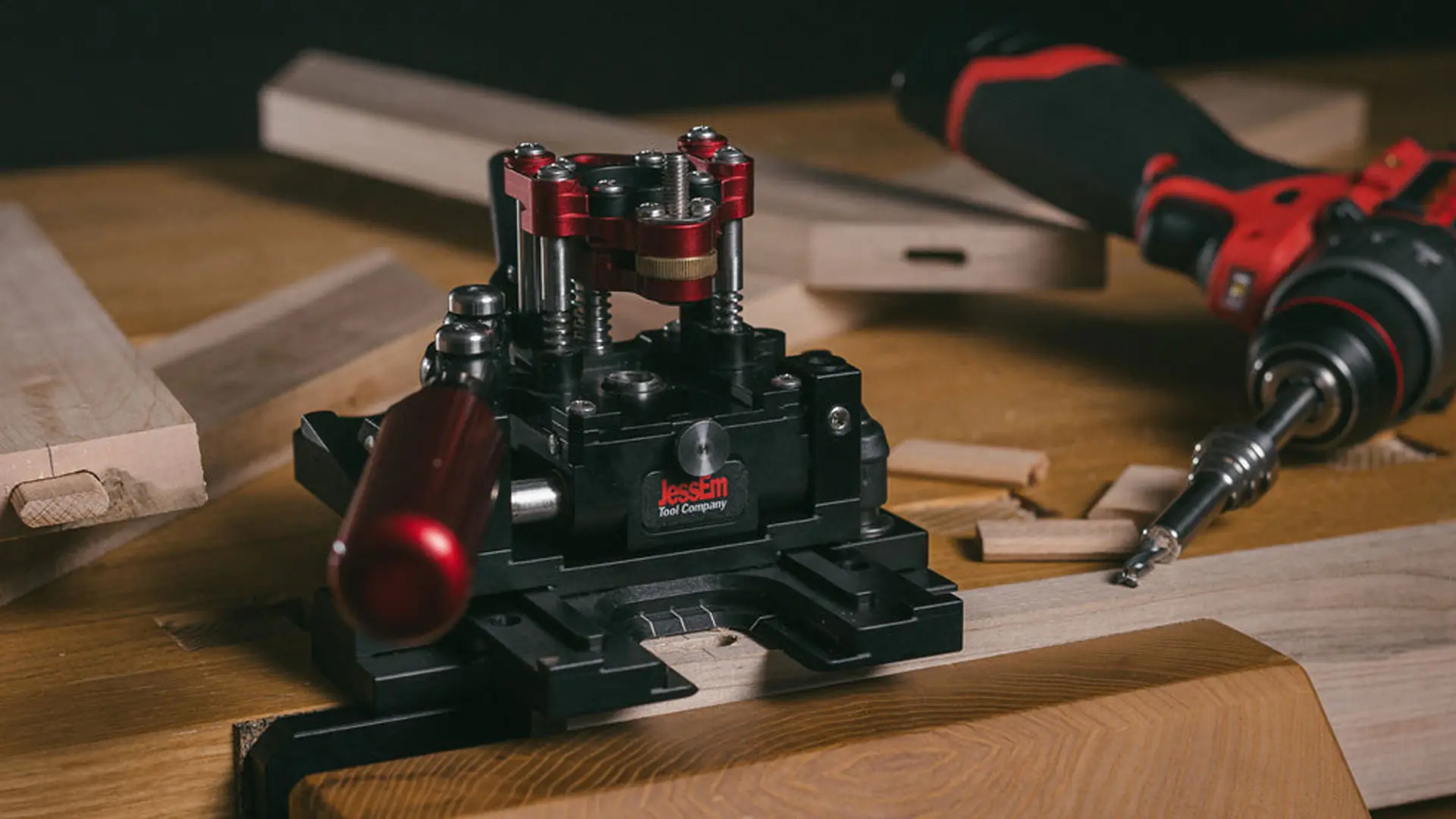

The Pocket Mill Pro is a device that allows you to quickly and easily create the necessary recesses using only a drill or cordless screwdriver (>= 1200 RPM) and a milling drill corresponding to the material thickness of the flat dowel. Typical for the manufacturer, besides proven functionality, appealing design, and high-quality workmanship, is the choice of materials. Except for the extraction nozzle, which is made of plastic, the Pocket Mill Pro is a solid all-metal construction primarily made of anodized aluminum and stainless steel. It consists of a carriage and the actual main body.

Usable flat dowels:

Both commercially available, pre-fabricated flat dowels and cut-to-length bulk material can be used. Additionally, it is possible to create your own dowels from suitable material (utilizing scraps) using half-round or quarter-round cutters, or by rounding the corners of a strip with a few plane strokes.

| Features | |

|---|---|

| Scope of delivery | 2 suction nozzles, milling cutter Endmill Kit 6 mm (Article 332097), main body, mounting bracket, carriage |

| Material | Stainless steel, anodized aluminum, plastic, brass |

| Version | with angle stop |

Additional links / downloads

0 of 0 reviews

Average rating of 0 out of 5 stars

Login

Also interesting

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available in 33 days, delivery time 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available in 43 days, delivery time 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available in 14 days, delivery time 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany