With a sharp knife, preparing food becomes a pleasure. The tedious work with dull blades that crush rather than cut tomatoes comes to an end when using Japanese kitchen knives—provided a few simple rules are followed.

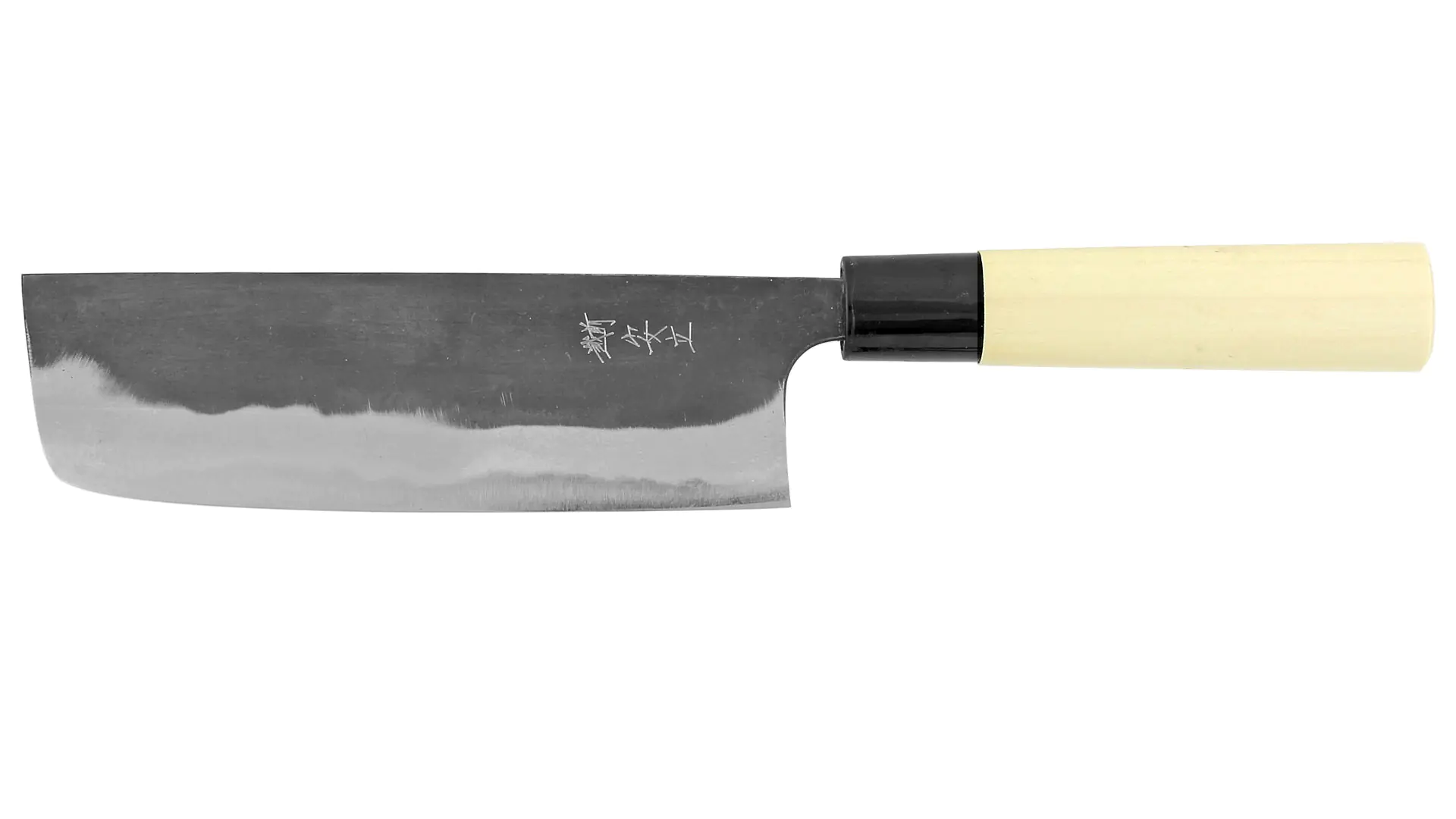

The traditional Japanese knife, called “Hocho,” is typically forge-welded from two or three layers of steel or iron.

In Ryoba-type knives (= double-sided), the cutting steel is embedded between two layers of iron. These knives are sharpened on both sides.

Kataba-type knives (= single-sided) consist of one layer of cutting steel and one layer of iron. They are sharpened on one side and are particularly suitable for delicate cutting tasks such as filleting.

A certain degree of sensitivity is needed when handling these knives: The sharper a blade, the more delicate it is. For this reason, Hocho knives should never be cleaned in the dishwasher. The mechanical cleaning process can damage the delicate edge, and the wooden handle can degrade over time due to moisture and heat.

Traditional Japanese knives are not stainless—another reason to avoid machine cleaning. It is still true that the best knife steels are made of carbon steel, which is not stainless. To prevent rust, it is enough to thoroughly dry the blade after use. For extended storage, it is recommended to lightly coat the blade with oil—ideally camellia oil. A dark patina on the blade is normal for carbon steel and is not a defect.

If rust does occur, there is no need to worry: It will disappear when sharpening. Additionally, a rust eraser can be used— a tool made of silicone-embedded silicon carbide particles that effectively and gently removes rust.

No blade stays sharp forever. Japanese Hocho knives are best resharpened on Japanese water stones. Even without prior experience, this can be done with a bit of practice—an instruction manual is included with each knife. Dry-running sharpening machines and honing steels are not suitable for these knives.

The soft steel layers of Japanese knives can permanently deform under improper stress and do not spring back to their original shape like European knives. Such deformations must be manually corrected. This apparent disadvantage is offset by a significant advantage: The soft outer layers allow the hard cutting layer of carbon steel to be hardened to up to 61 HRC without the risk of cracking.

Anyone who follows these guidelines will enjoy a traditional Hocho for a long time.

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available in 104 days, delivery time 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available in 104 days, delivery time 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available in 73 days, delivery time 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany