Artificial sharpening and honing stone

Our extensive range delights the connoisseur, as they are sure to find among the many sharpening stones from several renowned manufacturers the perfect stone for their task.

We carry stones from various manufacturers because each has different focal points and strengths and weaknesses are widespread; in other words, to create an optimal sharpening set, most woodworkers need stones from multiple manufacturers.

If you can embrace the characteristics of specific stones, you might also commit to a single manufacturer, which can be advantageous in certain cases. There is no one-size-fits-all solution; the stones must suit you and your working style.

About the individual manufacturers/brands:

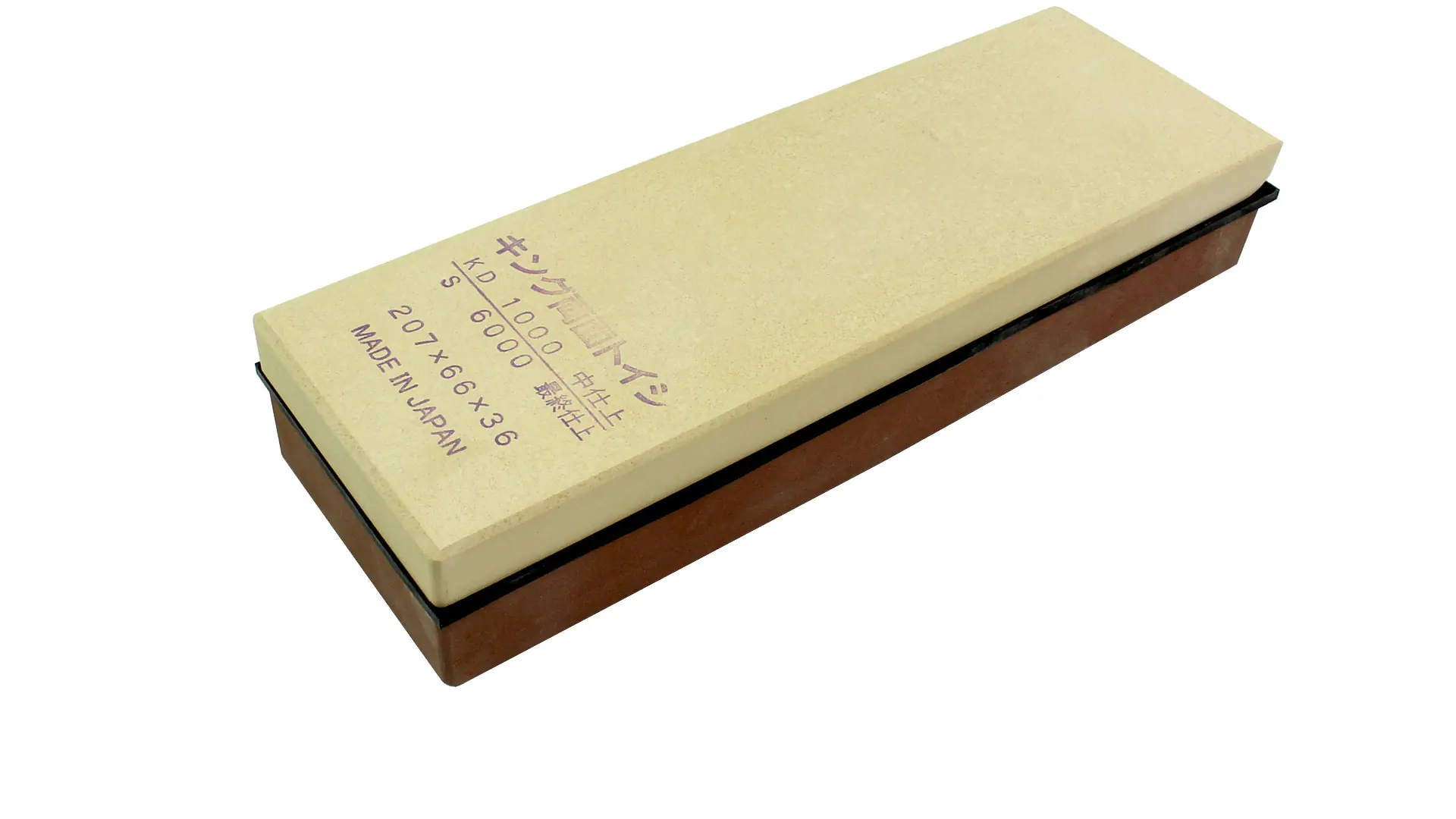

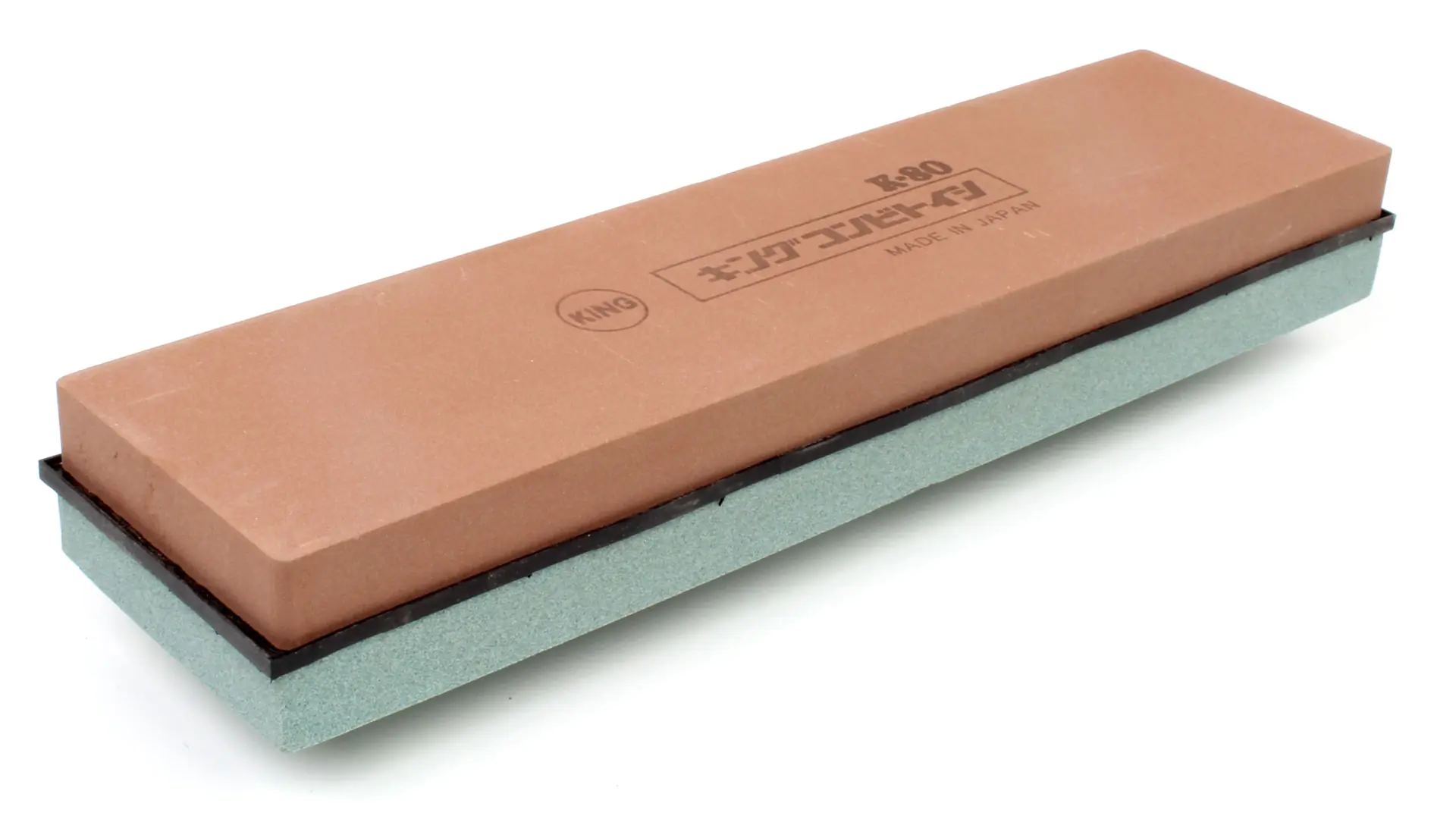

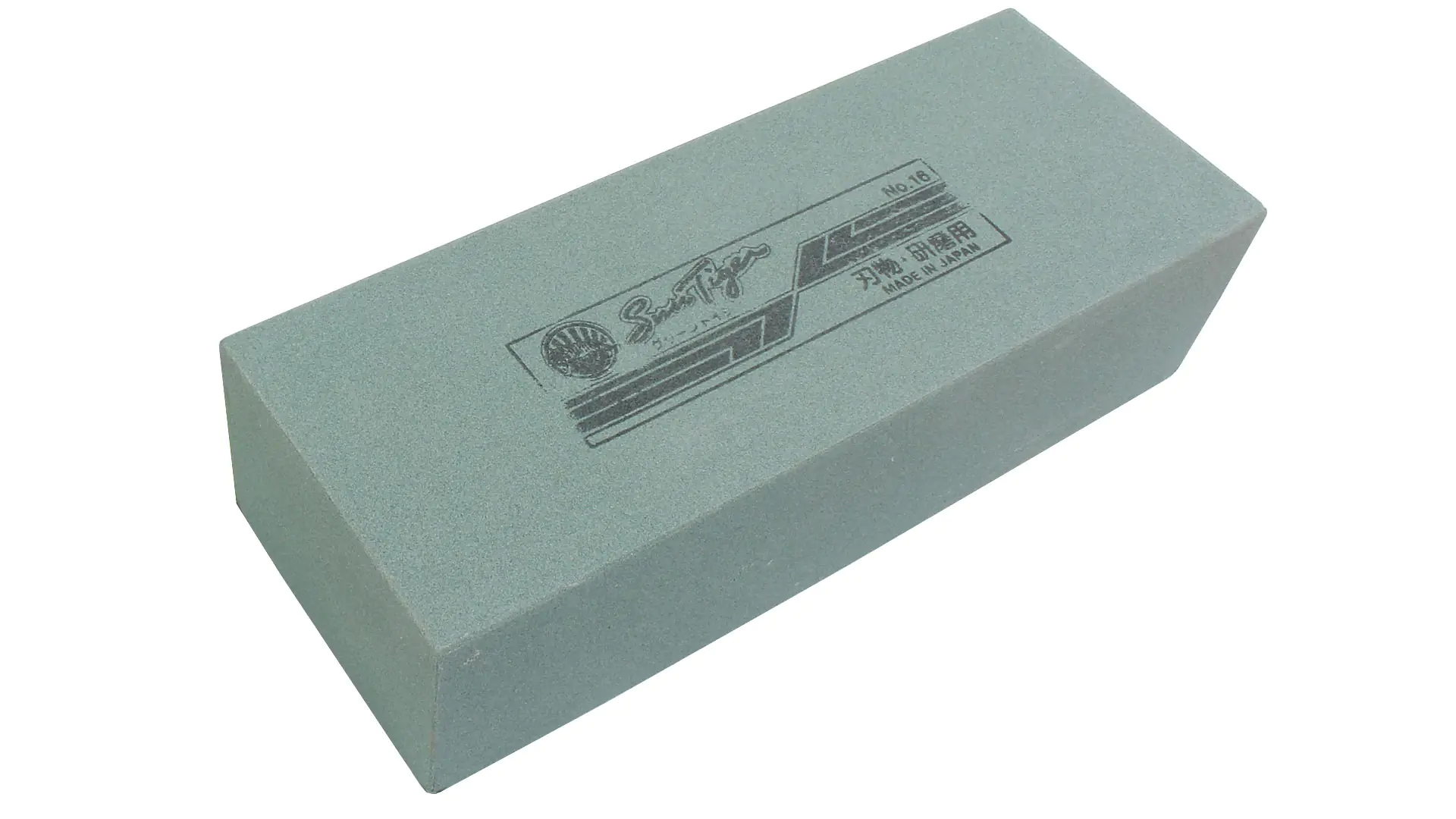

King and Sun Tiger

The Japanese sharpening stone manufacturer Matsunaga from Osaka, with the brands King and Sun Tiger, is probably the longest-known manufacturer of Japanese water stones in the West.

King sharpening stones are consistently soft, providing a pleasant feeling when sharpening because you can almost sensually perceive the material removal on the blade. Due to their softness, these stones need to be trued (made flat again) more frequently.

The Sun Tiger roughing stone with grit 240 hollows relatively quickly, but you are rewarded with an extremely high material removal rate, for instance, when grinding out nicks in knives. You can grind out a nick in just a few minutes with this stone, but it should be trued after each use if a straight edge is important. Keep in mind that this isn’t for everyone, but if you accept it, you have a wonderful, fast-working stone. With this stone, you can use significantly less pressure than with the SHAPTON 120, as the loose grit of the SUN TIGER grips immediately.

SUEHIRO and CERAX

The Japanese sharpening stone manufacturer Suehiro from Niigata, with the brands Suehiro and Cerax, is especially popular with the second brand, Cerax. Cerax stones are characterized by not wearing as quickly as traditional Japanese water stones. With the 8000 grit stone, you achieve the sharpest edges and polished mirror surfaces on chisels. Besides the traditional 6000 grit SUEHIRO finishing stone, we also offer an intermediate size with grit 3000.

We recommend not storing SUEHIRO and CERAX stones in water continuously; it’s sufficient to soak the stone for 5 minutes before use. The surface of these stones can dissolve if stored in water continuously. This is not a disadvantage, as it indicates a small amount of binding agents: the fewer binding agents, the faster fresh grains are released, making the sharpening process more effective. „Baked” in an oven from aluminum oxide with added binding and filling agents.

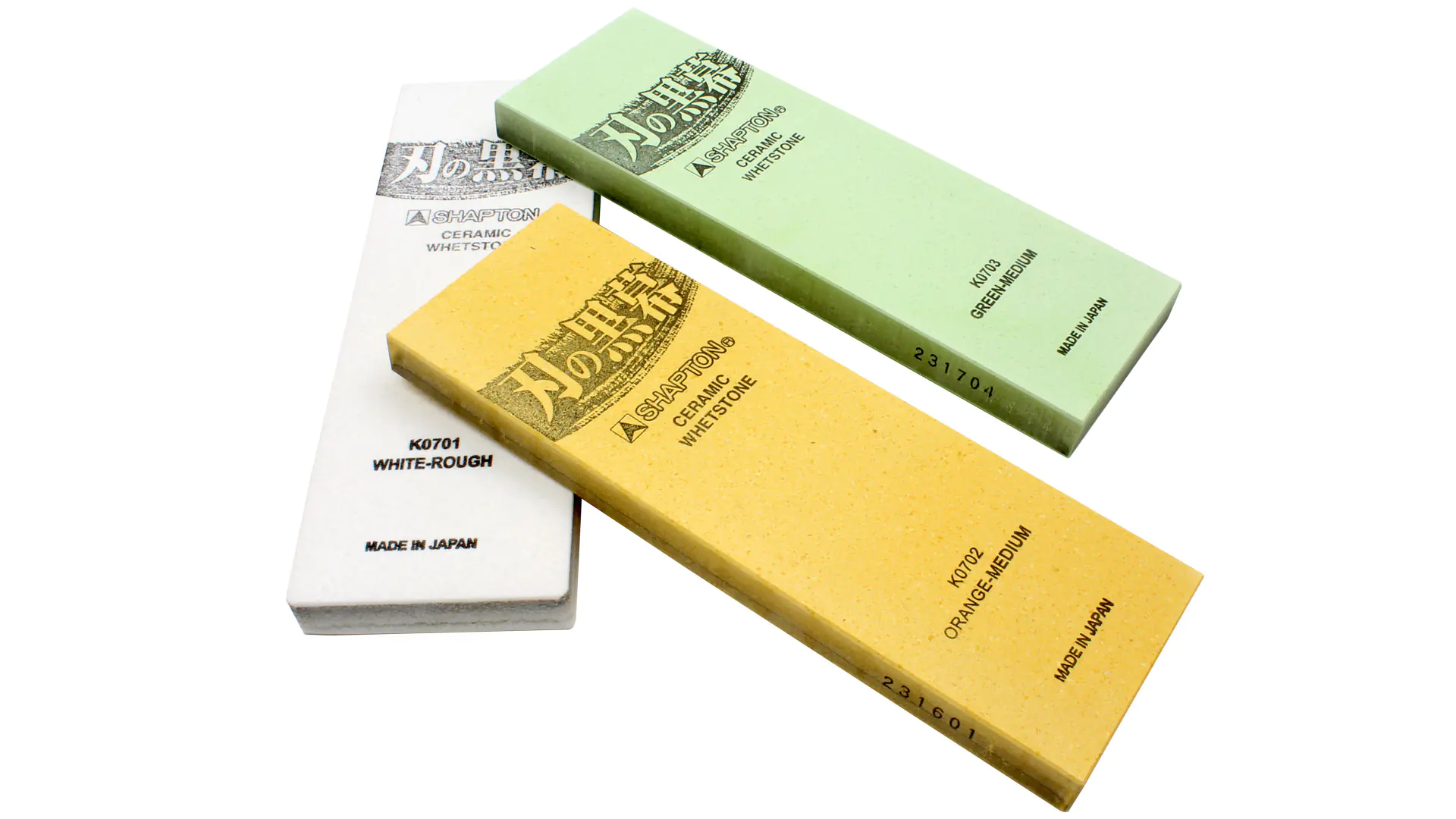

SHAPTON Ha-no-kuromaku Series

The Japanese sharpening stone manufacturer Shapton from Nabatame, Tochigi Province, produces arguably the hardest Japanese water stones. Unlike almost all other brands, they retain their shape best and need to be trued less frequently.

SHAPTON sharpening stones show their strength most during roughing and effective sharpening. The sharpening process feels quite different from soft stones. You can really feel the hardness of the stone and might think you need to check multiple times if it’s actually working. It is! And quite quickly!

The 120 grit is similar in speed to the 240 grit SUN TIGER from Matsunaga, but it retains its shape very well in contrast. The effectiveness can be increased by applying higher pressure on the coarse stone.

The 1000 grit SHAPTON sharpens faster than traditional Japanese 1000 grit stones, but the scratch pattern is somewhat coarser than even from a traditional 800 grit stone.

Unlike traditional 8000 grit stones and the 8000 grit CERAX, the SHAPTON 8000 barely polishes and leaves a highly fine matte scratch pattern. Whether this affects the final sharpness has not been conclusively clarified, but it is known that, for instance, some high-quality Japanese natural stones also do not leave a polish, yet the achieved sharpness is excellent.

It’s sufficient to wet SHAPTON stones with water before use and as needed; a few minutes of soaking like traditional stones is not necessary.

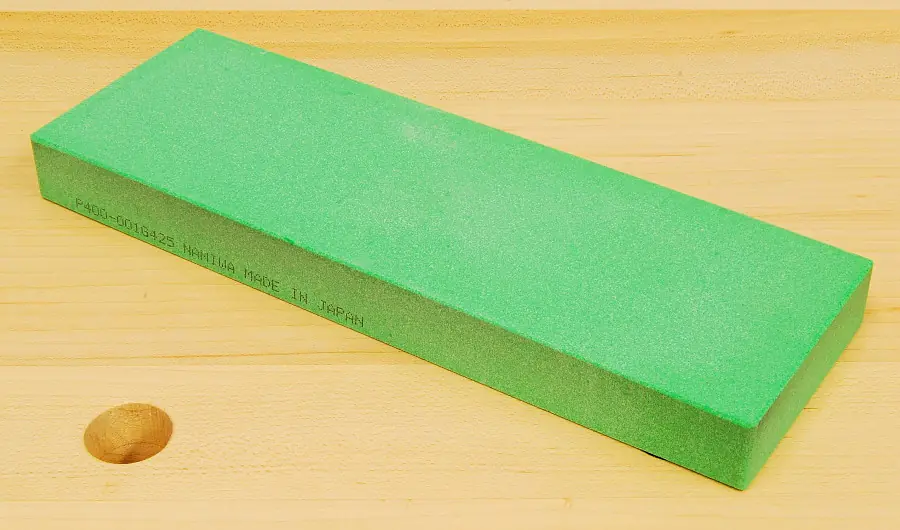

NANIWA

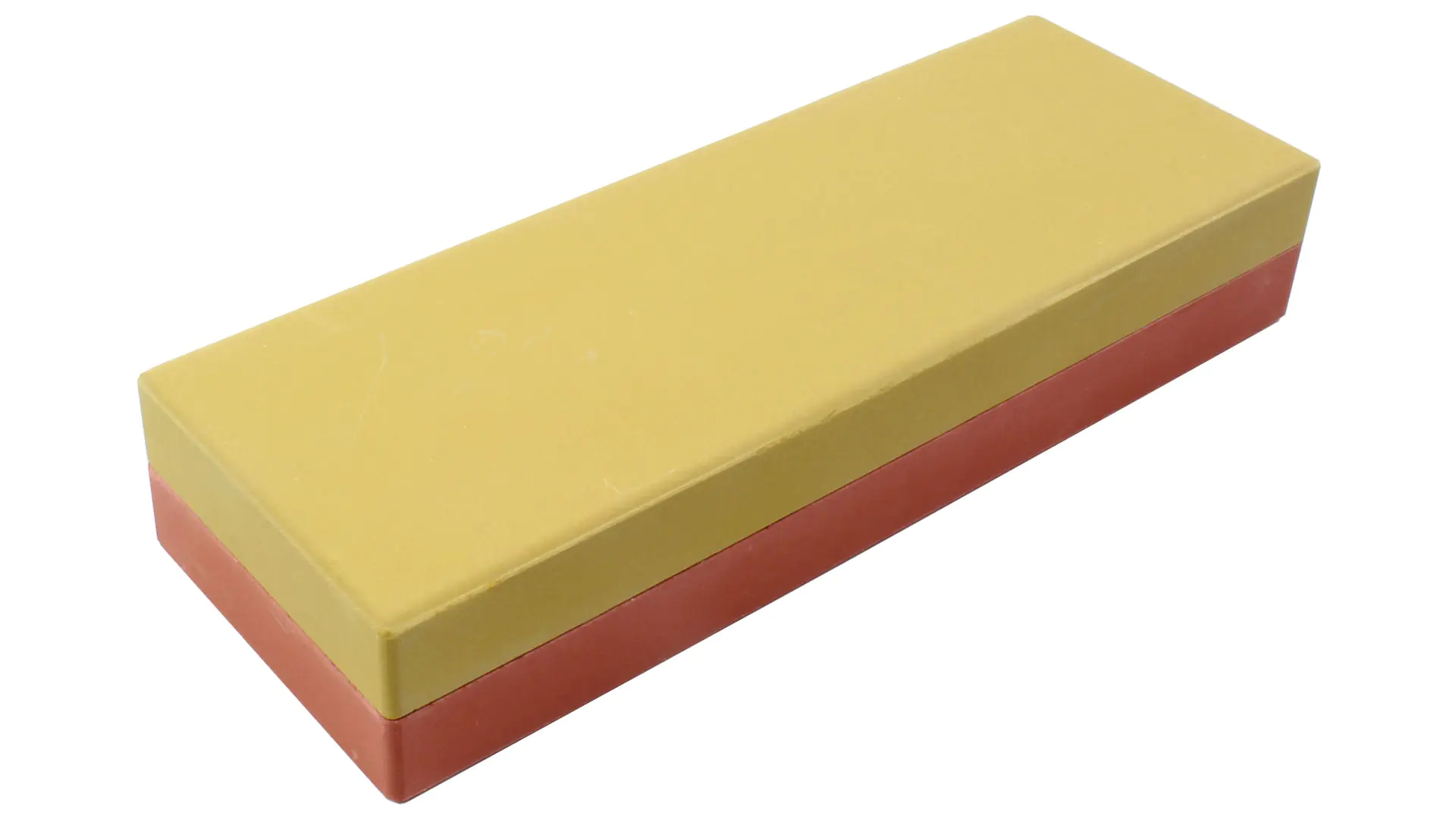

Lobster

The „Lobster” from Naniwa is a soft, resin-bonded stone, and it provides a pleasant feeling when sharpening because you can clearly perceive the material removal on the blade. Because the Lobster stones are soft, they need to be trued (made flat again) more frequently.

The „Lobster” roughing stone with grit 220 is one of the most affordable roughing stones and still very effective. It should be soaked in water for at least 5 minutes before use. Please store it dry after use.

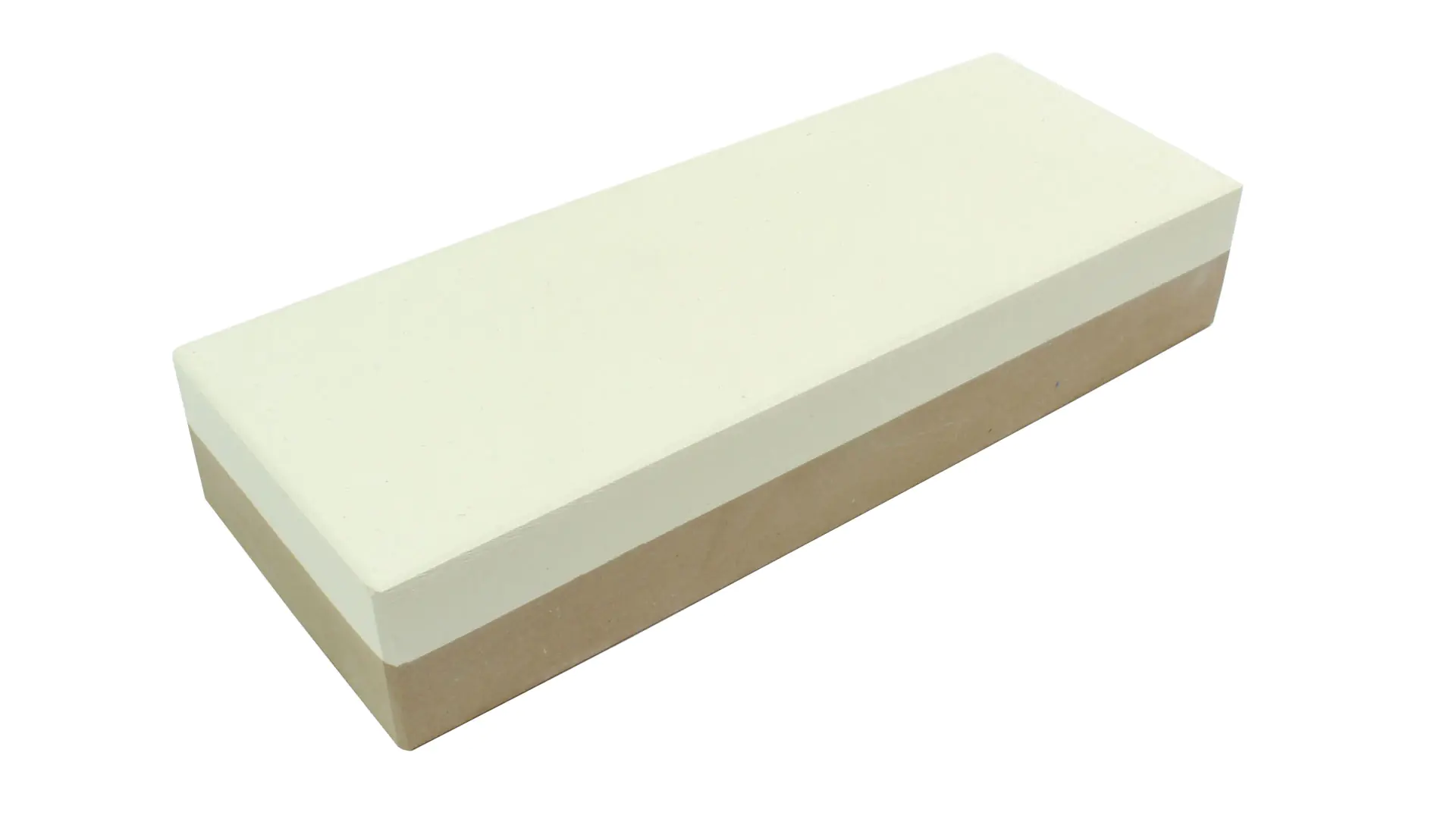

NANIWA Super Stones / Advance

The Japanese sharpening stone manufacturer Naniwa from Osaka produces what are probably the best finishing stones.

NANIWA Sharpening Stones are significantly harder than King stones and slightly harder than Cerax stones, but much softer than Shapton stones. Despite their hardness, it feels like you’re sharpening on a soft stone. The material removal on the blade is almost sensually perceived. This is one of the secrets of Naniwa stones: they create a pleasant feeling when sharpening like on a soft stone, while hiding the fact that they are actually hard. You only notice this later when you realize that they only hollow very slowly.

The Naniwa stones show their special strength in the fine area. No other stone achieves such fine edges.

Note on a name change at Naniwa: The Super Stone series has become the Advance series. The properties of the stones remain unchanged.

NANIWA PROFESSIONAL / CHOCERA PRO STONE

With the „PROFESSIONAL STONE” series, Naniwa offers a top product in sharpening stone technology. The Professional Stones are significantly harder than the Sharpening Stones series from the same manufacturer. Naniwa targets this product at professionals with the highest demands among users. Especially those who don’t have much time and want to achieve a quick and clean sharpening result in between are well served with these stones.

Professional Stone sharpening stones with their hardness are quite close to Shaptons. They are bound significantly more firmly than the Sharpening Stones and hollow only very slowly. Especially in the coarser range—grit 3000 and below—they are significantly superior to these in terms of sharpening speed. When grinding out nicks, the 400 grit Professional Stone roughing stone is even faster than the 220 grit Sharpening Stone and slightly behind the Shapton 120 grit. Generally, it is enough to wet the surface of the stone with water.

Traditional Stones

If the other Naniwa sharpening stones are too soft for you, you will find a good alternative here. The Standard Stone (formerly called Traditional) is a bit harder and thus doesn’t hollow as quickly as other Naniwa sharpening stones. This stone is an all-rounder and suitable for almost all tool steels. Soak the stone for a few minutes before use, 10 to 15 minutes are sufficient. Re-wetting may be necessary as especially the 220 grit stone is quite thirsty. Storage should be dry, as we also recommend for all other sharpening stones.

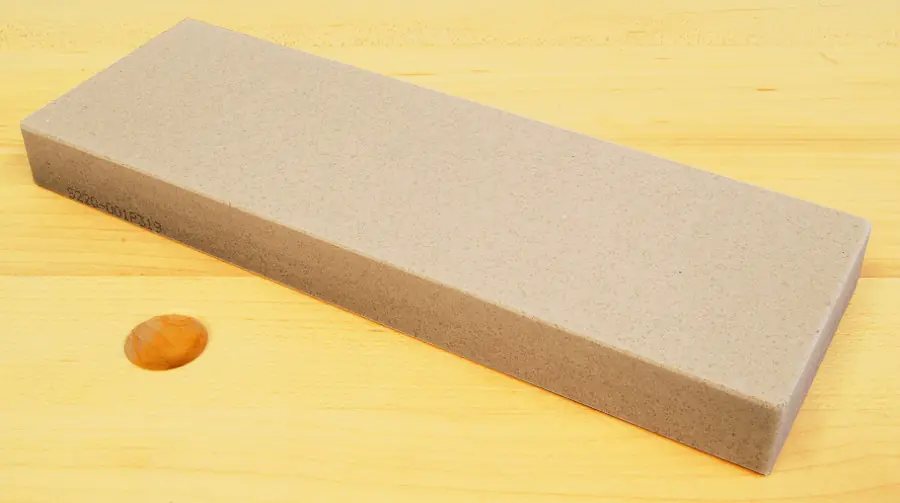

IMANISHI Bester

BESTER sharpening stones from the manufacturer Imanishi from Kyoto offer a sharpening feel almost like natural stones. BESTER sharpening stones have medium hardness, don’t require an excessive amount of water, and you can work very quickly with them. You can hear and feel that a significant material removal is taking place, and when you look at the blade, you’re amazed at the amount. The stone responds quite directly to the user’s actions—those who have rubbed on stones without feeling any change on a blade or couldn’t develop a sense of what’s happening will very much appreciate this.

The wear of the stone and the associated hollow grinding are relatively low. You should soak them for 5 minutes. The coarser stones may require an additional splash of water after a few minutes, which is rewarded with higher sharpening speed. Suitable for both carbon steels and stainless steels. The grits 400, 4000, and 8000 are somewhat harder than the grits 700, 1000, 1200, and 2000. The size specifications are only approximate; most Bester sharpening stones are a few mm larger.

SIGMA Select II

The sharpening stone manufacturer SIGMA Power Corporation from Tokyo targets its top series Select II for users of high-alloy steels such as HSS. Even with these stones, there is a visible effort to create a sharpening feel similar to natural stones. Unlike resin, magnesium, or cement-bonded stones, the Select II have no binding agents. Instead, the vitrification process is used to bind the grains in these stones. By increasing the viscosity during the cooling of the sharpening stone mass, crystallization is prevented, creating amorphous material analogously to glass production. This process is expensive, but the Sigma Select II are true steel eaters.

Not only is steel removed quickly, but the stone also wears quickly—creating quite a slurry while sharpening—the price for speed! Therefore, it must be trued more often, but this is very quick with this stone.

JUUMA Cobalt Blue

JUUMA sharpening and finishing stones represent a simplified sharpening principle with the highest possible quality in the offered grits. Of the three offered stones, you only need two: Choose either grit 800 or grit 1200 depending on the usual condition of your chisels or knives before sharpening. If you are one of those who delay sharpening a bit too long, choose grit 800; otherwise, as a regular sharpener, opt for grit 1200. After sharpening with grit 800 or 1200, move on to grit 2000 for a fine finish or to remove the burr. If you can’t get much out of a 6000 grit stone due to lack of experience and practice—properly learning to sharpen to the highest sharpness takes time—you are well served with the final finish of the JUUMA grit 2000. Furthermore, you can always add an 8000 grit finishing stone from our extensive sharpening stone program as your experience grows.

Why the name Cobalt Blue? JUUMA Cobalt Blue stones consist of aluminum oxide and a binding agent. An addition of cobalt serves to mitigate stone wear during use and increase sharpening speed. This is particularly noticeable with Blue Steel (blue paper steel, often used in Japanese planes and chisels), where the stone grips much better. Cobalt is responsible for the blue color of the stones.

JUUMA Whetstone Pro

Water stones based on corundum with a tendency towards a somewhat softer expression, increasingly towards the finer grits. The surface can be easily trued with appropriate measures.

The stones provide good feedback. Slurry forms quickly, and the surface color changes from „white” to „black” in a short time. This reflects the considerable material removal. Suitable for all steels. Even PM-V11 might lose its „fear” for some users. Smooth sharpening feel without feeling scratchy.

To avoid distortion of the stones, they are provided with a plate of tempered glass. Grit indication on the back of the stones, secured by a glass plate.

Regarding water requirement, they are „Splash-and-Go” stones. That is, pre-soaking is not necessary; usually, wetting the surface at the start of work, followed by a modest additional splash, is sufficient. We definitely advise against soaking orgies, as this can otherwise lead to the formation of hairline cracks similar to the NANIWA Professional/Chocera stones. However, due to the glass base, stone breakage is not a concern. In further application, this remains a cosmetic flaw without affecting the sharpening result. Neither acid nor alkali resistant (kitchen cleaners!). Storage should definitely be dry!

For a complete setup in sharpening and honing, not all 5 stones are necessarily required; even with 3, you can be well served.

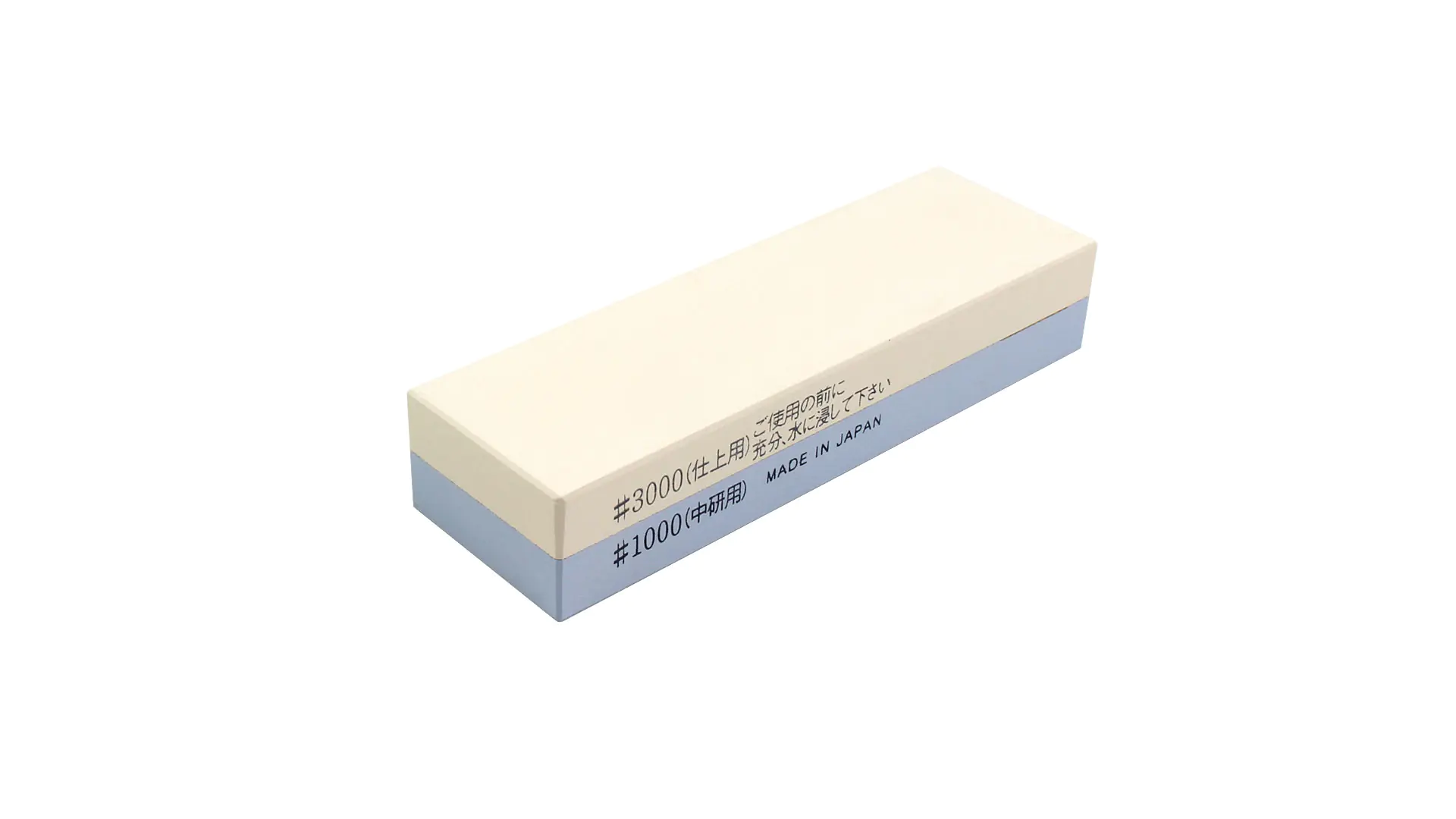

Combination Sharpening Stones, Small Sharpening Stones

For many users, a combination stone suffices. For those who sharpen frequently, it may be a disadvantage that only one sharpening side is available for each grit size—as opposed to a stone with only one grit where you can use both sides. This is significant when a stone is somewhat hollowed, and you don’t feel like truing it immediately.

We offer several smaller combination sharpening stones, which are particularly interesting for a small budget due to their very favorable price. Our mini combination stone with a plastic handle is for those who want an affordable all-purpose sharpener for the kitchen or on the go without investing too much. The composition of the small stones is of the same quality as the large stones. However, sharpening with small stones is somewhat more cumbersome because generous sharpening movements cannot be performed. For chisels and plane irons, where a straight and right-angled bevel is important, a small stone does not allow as much precision as a large stone. This should be considered when deciding on a sharpening stone.

The two Cerax stones are particularly popular with knife owners due to their especially favorable price-performance ratio. Beginners tend to choose the stone with the 1000/3000 combination, while experienced knife sharpeners opt for the 1000/6000 combination.

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available in 55 days, delivery time 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany