- Tools

- Drilling & Milling

- Machine Accessories

- Workshop

- Sharpening & Grinding

- Surfaces

- Measuring & Testing

- Household & Garden

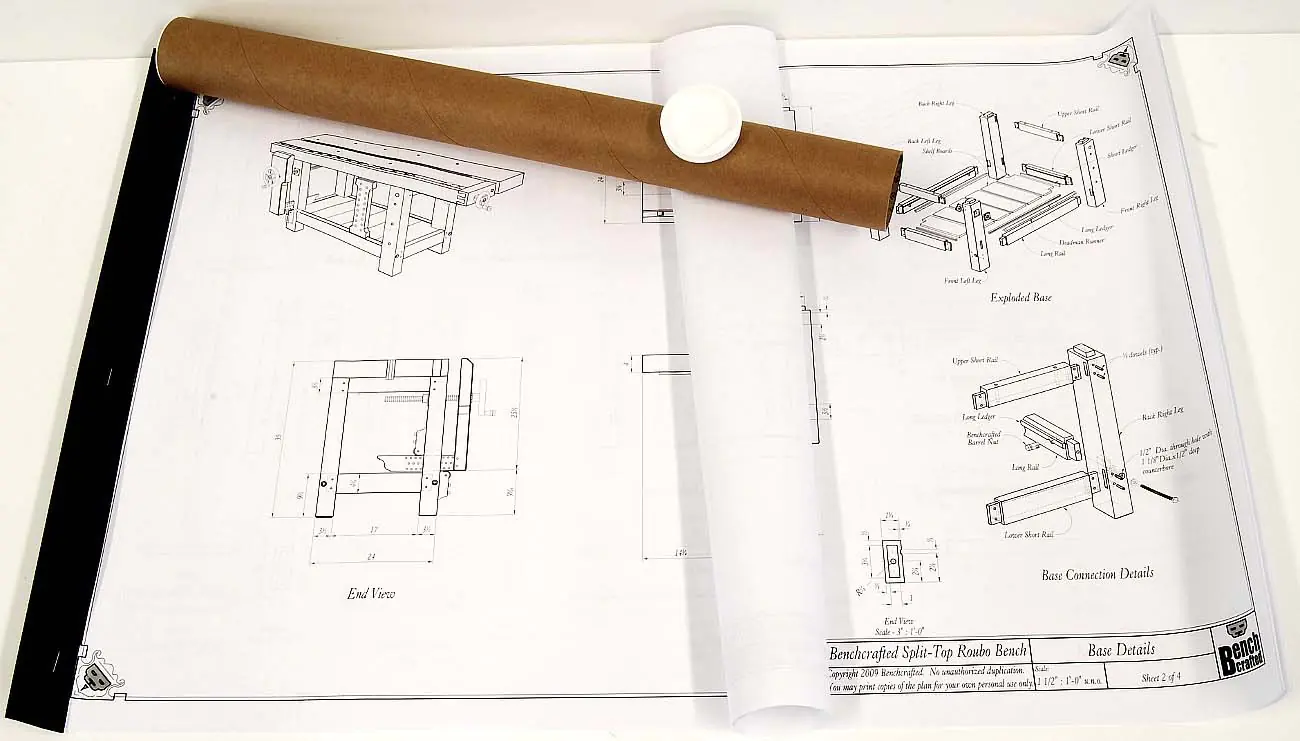

BENCHCRAFTED Workbench Accessories

The vise at your workbench should not be a constant annoyance but a firm part of your workflow and fit well with it. Like a well-adjusted plane, the vise should allow you to focus entirely on the work and not on the tool. A vise should be smooth, easy, and quick to operate. This fully applies to the vises from Benchcrafted. Benchcrafted manufactures parts for some vises in the USA, often inspired by historical models and somewhat uncommon in Europe.

Foremost among them is the "Leg Vise." This is a vise mounted on the leg of a workbench. The slab (or the apron or dog strip) of the workbench forms the rear jaw. The front jaw is the upper end of a sturdy board that extends almost to the floor. The lower end of the board is connected to the leg of the bench with the help of a parallel guide, and the spindle is located further up. This vise is very versatile due to its great depth. The construction of this vise is described in the book „Le Menuisier Ebeniste” by A. J. Roubo, which appeared at the end of the 18th century. (The „Roubo Bench” is also inspired by this book and can be seen as an evolution of a historical workbench.)

Also uncommon in Europe is the „Wagon Vise.” This is a tail vise where a sled runs in a recess (sled track) of the workbench. The sled is moved via a spindle and has a hole for a bench dog. With the help of the wagon vise, you can clamp workpieces on the surface of the workbench, for instance, if you want to work on them with a plane.

BENCHCRAFTED Leg Vise

Leg vises were very popular before the industrially manufactured steel vises became common. As the carpenter’s vises from Record (today produced by other, sometimes renowned manufacturers and also found in our product range) became dominant, leg vises slowly disappeared. Leg vises offer more space for the workpiece than steel carpenter’s vises. Unlike a carpenter’s vise (and also unlike the classic European-style front vise), a leg vise does not have guide rods, allowing the workpiece to be pushed laterally up to the spindle.

Steel carpenter’s vises have a working depth from the top of the workbench to the guide rods and spindle of about 100 mm (4 inches) (similarly with European front vises). Leg vises typically have more than double the depth at about 230 mm (9 inches). Leg vises also develop greater clamping pressure due to the leverage offered by the low parallel guide. Additionally, they are faster and easier to maintain than steel vises. The auxiliary jaws made of wood, necessary for a steel vise, are not needed for a leg vise. Here, the wooden vise itself, together with the slab and leg of the workbench, form the clamping jaws.

We strongly advise you to start installation only when you have all the fittings on hand! Unfortunately, we cannot guarantee that previously published dimensions are always up to date or that manufacturers will not change dimensions without notice.

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available in 85 days, delivery time 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany