We recommend Japanese natural sharpening stones only for experienced users who have already extensively familiarized themselves with artificial Japanese sharpening stones. Natural stones do not reveal themselves to everyone and present many uncertainties regarding grit, which can never be precisely determined, as well as hardness and suitability for certain steels.

For many years, we refrained from offering Japanese natural sharpening stones. There were several reasons for this.

Variety of Artificial Stones

Firstly: The range of industrially manufactured water stones is extremely diverse and practically covers every need – often even multiple times. Thus, there are virtually no unfulfilled wishes.

Predictable Quality

Secondly: With artificially manufactured stones, it is guaranteed that they are consistently homogeneous and always grind in the same way – whether at the beginning or the end when the stone has already become thinner. With natural stones, this is not predictable, as usually only the surface is visible. The next layer can already have different properties or contain hard inclusions that can significantly limit their usefulness in further use.

Assessability

And thirdly: Too little is known about natural stones to reliably assess what is actually being purchased and whether the price is justified. Moreover, each natural stone is unique. While the properties of an artificial stone can be transferred to an entire series, in theory, each natural stone would have to be extensively tested – which would further increase the prices. Additionally, in many cases, the origin stamp of the quarry would be lost through testing.

Why Now After All (1)?

In the realm of artificial stones, little new is expected in the near future. Only selling without discovering new things would be unappealing in the long run. Hence, contact was made with an expert who visits wholesalers, visually inspects stones, and individually purchases them in selected quality. This sparked interest – and now some of these stones can be found here.

Why Now After All (2)?

Natural water stones are a cultural asset. They have accompanied human cultural development for millennia – from agriculture to woodworking to food preparation. Cutting tools and their sharpening stones form the basis of many traditional crafts. The fact that modern artificial stones receive the highest praise when they „sharpen like a natural stone” shows: HighTech has always existed in the form of natural stones – provided the right deposits were found.

Who Are These Natural Sharpening Stones For?

Beginners are best off initially working with inexpensive artificial stones, which are perfectly adequate for a proper working sharpness. Those who develop higher demands switch to high-quality artificial stones – often a real revelation. Many feedbacks confirm that the achieved sharpness is unexpectedly high.

However, those who have already reached this point, remain curious, and are willing to accept surprises should take a closer look at the range of natural stones.

3 Sharpening Steps

Archaeological finds from the late Jomon period (around 1000–300 BC) show that the sharpening process was already divided into three work steps: roughing, grinding, honing. This classification essentially applies to this day.

The abrasive material of natural honing stones consists of fine, round, siliceous grains of 0.2–0.3 μm size, bonded with iron oxide or other natural additives that enhance the grinding effect.

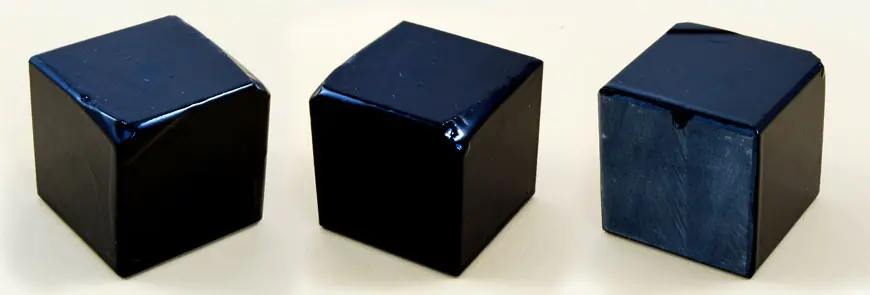

Appearance and Quality

A perfect natural honing stone of uniform color, high grain quality, and without blemishes is extremely rare and can cost a fortune. Such stones are referred to as „practical diamond.” Most natural stones, on the other hand, show color changes, spot patterns, or chipped edges – without significantly affecting the quality of the grinding result.

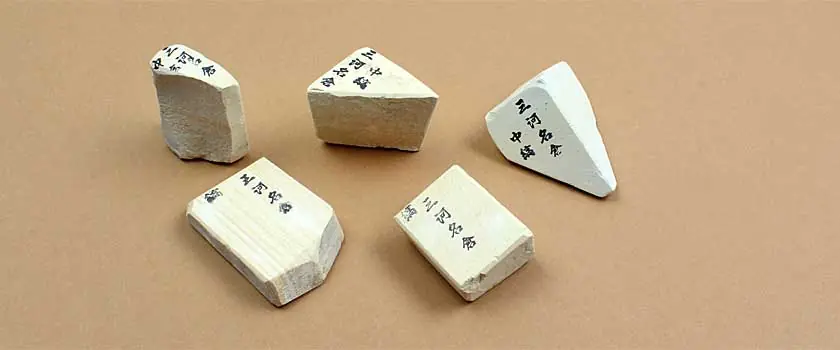

Deposits and Cutting

The deposits are largely depleted, almost all mines closed. Remaining material is cut to size as needed.

Names of the stones are based on the source mountain, e.g.:

- Western Mountains: Ohira, Shinden, Mizukihara

- Central Mountain: Atago

- Eastern Mountains: Nakayama, Ozuku, Kizuyama, Okudo, Shoubu, Narutaki

Cutting is done horizontally so that each sediment layer has approximately the same quality. This is comparable to tangential cutting in wood.

Soaking

Recommendations for soaking vary widely – from brief wetting to several weeks. A minimum soaking time of 30 minutes is sensible. Harder stones generally require more time than softer ones.

After soaking, the structure of the stone stabilizes for the sharpening process.

Storage

In Japan, natural stones are usually stored dry and in the shade. Moisture and frost should be avoided, as should rapid temperature changes.

Some experts recommend storing regularly used stones permanently in water, as they originate from underwater sediment deposits anyway. Nevertheless, there are many arguments for dry storage to prevent weathering in the long term.

Flattening

Natural stones must be regularly flattened to avoid hollows on the surface. This is crucial for precise grinding results, especially with woodworking tools.

Recommended methods for flattening:

- Flattening with sharpening stones of medium grit (600–1000)

- Use of diamond sharpening plates (grit 400–600)

After flattening, a thorough rinse is necessary to remove coarse grains. Finally, a Nagura stone is used to smooth, creating a fine grinding slurry.

Tip

It’s best to flatten and clean the sharpening stone immediately after sharpening. This way, it is already soaked and prepared for the next use. A neglected, hollow stone, on the other hand, inevitably leads to poorer results.

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany