- Tools

- Drilling & Milling

- Machine Accessories

- Workshop

- Sharpening & Grinding

- Surfaces

- Measuring & Testing

- Household & Garden

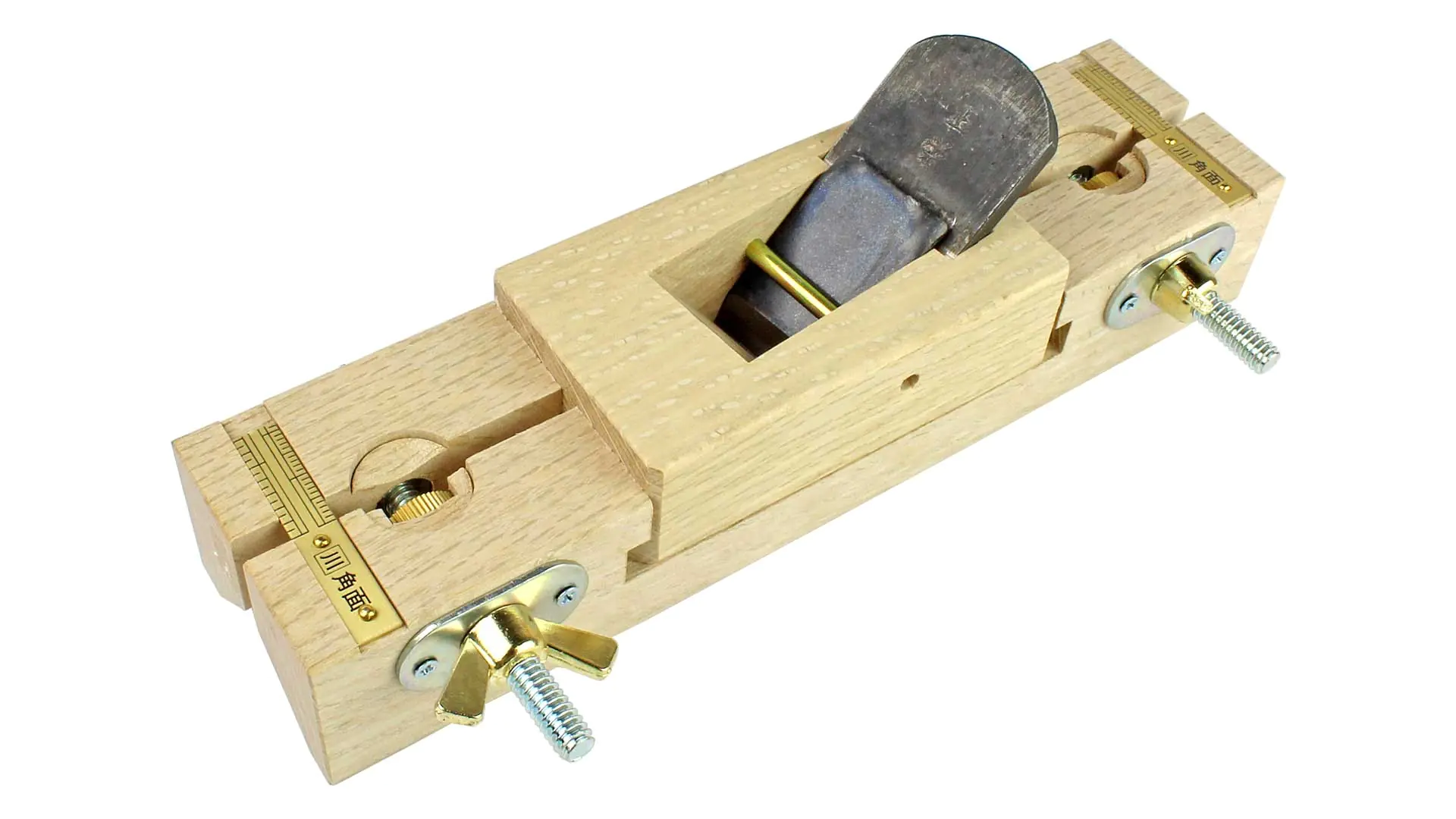

Other Planes / Specialty Planes

Available in 21 days, delivery time 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany