- Tools

- Drilling & Milling

- Machine Accessories

- Workshop

- Sharpening & Grinding

- Surfaces

- Measuring & Testing

- Household & Garden

Chisel

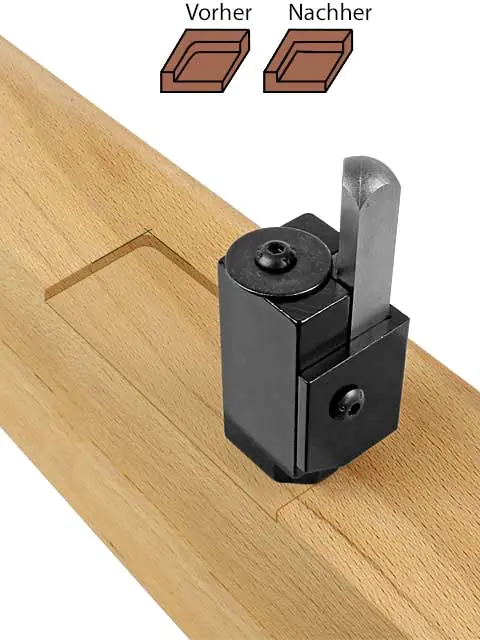

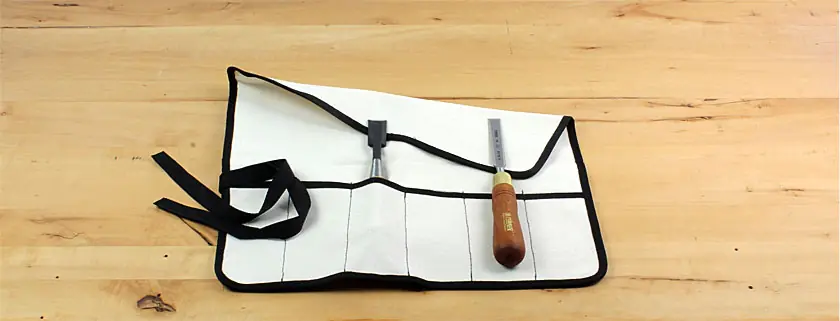

A chisel can only truly demonstrate its strengths when used according to its intended purpose. High-quality, finely ground chisels are designed for precise woodworking in the workshop and are less suited for use on construction sites—where dirt, cement residues, or increased theft risk might be factors. Conversely, fine woodworking should be done with a tool specifically designed and executed for that purpose.

Crucial to a chisel’s performance is a clean, sharp edge. The use of dry-running grinding machines is discouraged because the heat generated can soften the steel and significantly shorten its lifespan. Some manufacturers advertise their tools as „ready-to-use sharpened.” Nevertheless, it is advisable to flatten the back side (the flat side) before the first use. Only in this way can the chisel be reliably sharpened and honed later. Afterward, the bevel is sharpened, and both sides are carefully honed. For consistent results, a honing guide is recommended, especially when creating or correcting the bevel.

Properties of Carbon Steel and Alloyed Steels

Many older chisels—such as those rediscovered in attics or workshop inventories—are known for good sharpenability and long durability. These are typically tools made from unalloyed carbon steel. These steels contain no additional alloying elements and typically have a carbon content of up to 1.7%. Their advantages lie in high hardness and very good sharpenability. Disadvantages include a certain brittleness, low heat resistance, and lack of corrosion resistance.

To improve these properties, alloyed steels are often used today. Additives like chromium or nickel increase rust resistance, tungsten and molybdenum enhance temperature resistance, and titanium increases toughness. However, these modifications also come with limitations: sharpenability suffers, grindstones tend to clog, and in some cases, the durability decreases. What is advantageous for screw tools (hardness and toughness) can be disadvantageous for cutting tools like chisels.

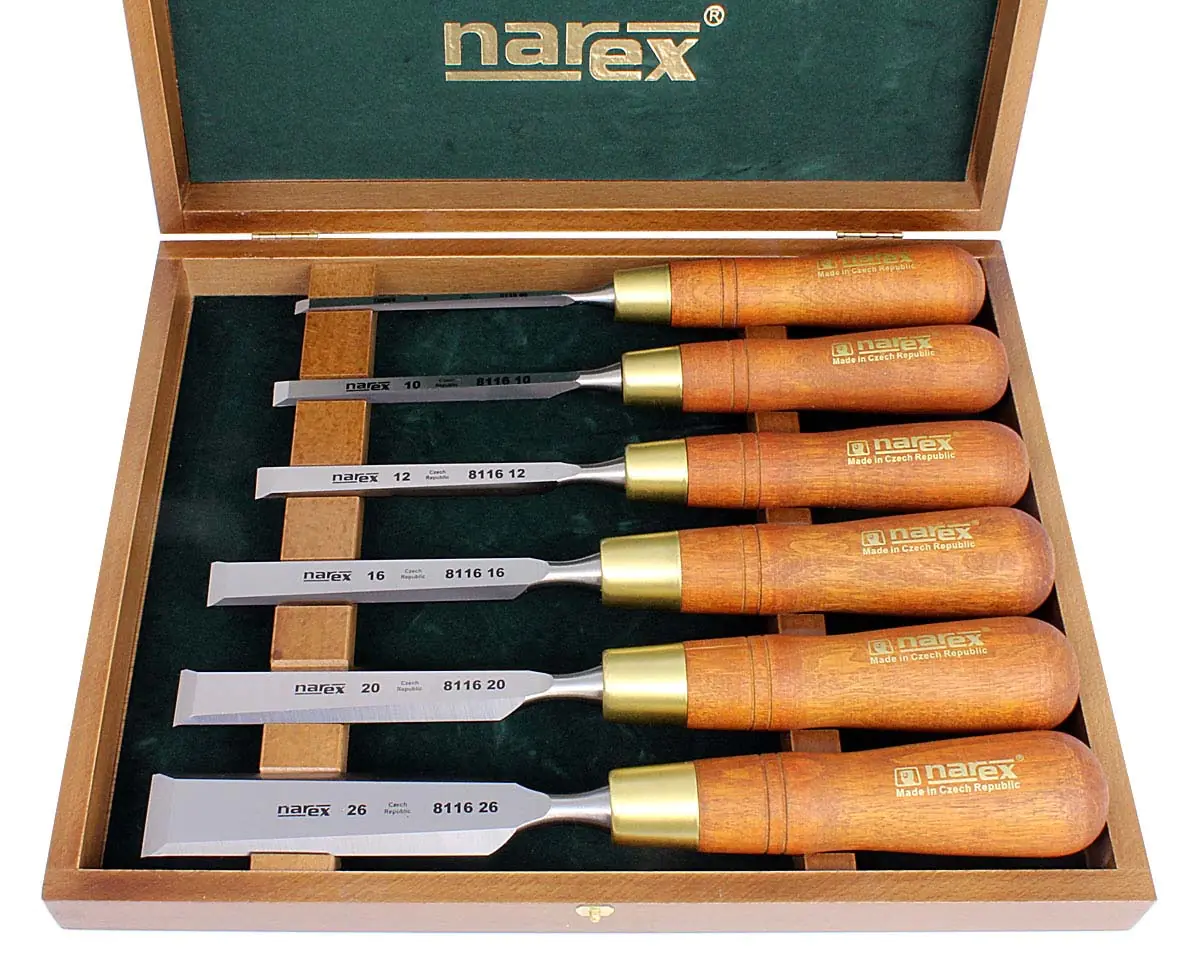

With handheld cutting tools, the advantages of carbon steel often prevail. Therefore, many high-quality chisels continue to use tool steels with a high carbon content. Traditional Japanese chisels often consist of pure carbon steel. Chisels from European manufacturers like Kirschen, MHG, or NAREX use alloyed steels that, due to their special composition, remain easy to sharpen. The choice of suitable material depends on the application area and individual preferences.

Available in 66 days, delivery time 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available in 66 days, delivery time 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany