- Tools

- Drilling & Milling

- Machine Accessories

- Workshop

- Sharpening & Grinding

- Surfaces

- Measuring & Testing

- Household & Garden

Japanese hatchets, axes, machetes

The Japanese hatchets and axes from Mizuno Seisakujo in Sanjo, Niigata Prefecture are typically made from 3-layer steel (Warikomi): a hard cutting layer in the center made of steel with a carbon content of 0.45%, and two softer iron layers on the outside. The forest axe and splitting axe are made from single-layer steel. The axe handles are made from Japanese white oak.

For the Japanese hatchets and axes, we use in the second line the term used by the manufacturer themselves. The names in Japan are very inconsistent and vary greatly by region. Masakari, for example, is often translated as „battle axe,” but as we’ve been assured, it is definitely not a weapon but simply refers to a hatchet with a wide blade. The generic term for „axe or hatchet” is more likely Ono, sometimes even Chouna. However, the latter more often refers to an adze.

In terms of use, a Masakari is defined as a hatchet for chopping wood that has been roughly split with a larger axe on the chopping block. The swing of the hatchet head on the Masakari backward allows for the handle to be held very close to the head to create fine kindling. This head shape also makes the Masakari interesting for sculptors.

The manufacturer of the Japanese splitting axe we offer calls it Kiwari, although in other regions the term Kiwari Ono is used. The blade is quite narrow but very thick to effectively split sections of logs. The Kiwari Ono is generally somewhat lighter than the Western splitting axe but has a slightly longer handle.

The closest to our small hatchets is the Bakin, a small kitchen hatchet for many purposes.

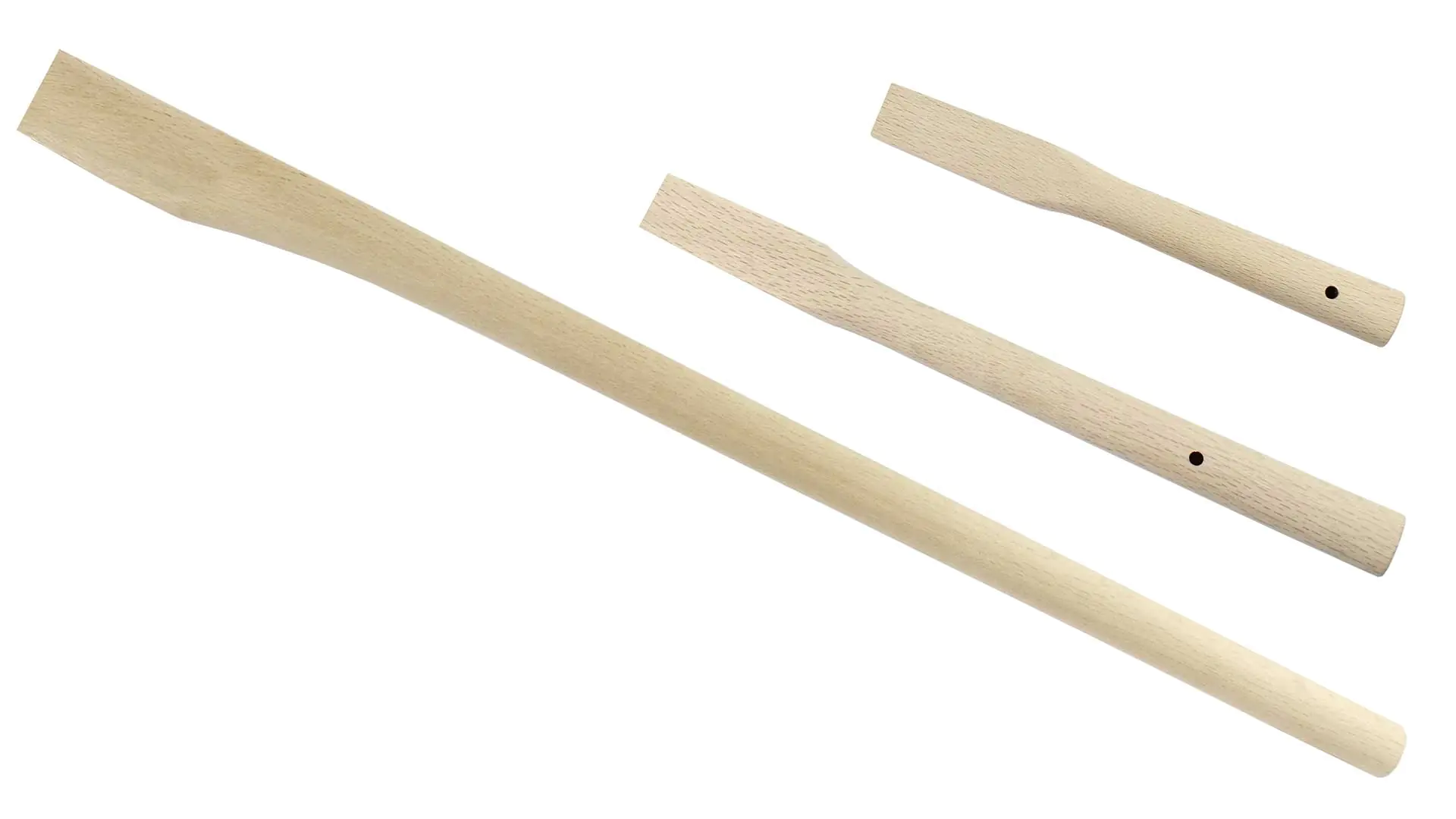

Considering the very different climatic conditions in Japan and Central Europe, we had to find a solution for the resulting handle fitting problem. In Japan, the air is usually very humid, while in Central Europe it is rather dry. If an axe is fully fitted there and stored here for a while, there is a chance that the handle may loosen and the axe head may fly off during use. Therefore, we initially agreed with the supplier that the axes would be fitted very loosely with protruding wedges. However, this led to some users having problems undoing the provisional fitting. Therefore, we are gradually switching and delivering unfitted, i.e., disassembled! Which are provisionally fitted and which come completely disassembled, you will find in the product description. The axe must be fitted by the user—preferably after an adaptation to the local climate for at least a week. For this, the shape of the handle must be slightly reworked to fit into the eye. For a precise fit, it may also need to be shortened by 1-2 cm to completely fill the eye.

Available, delivery time: 1-3 businessdays within Germany

Available in 4 days, delivery time 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany