-

Tools

- Japanese saws

-

Western saws

- Kits

-

Frame Saws

- Dovetail Saws and Backsaws

- Precision Saws - A cut above the rest

- Handsaws (saws without back)

- Scroll saws (marquetry saws, coping saws)

- Coping Saws (Small Hand Saws)

- Veneer Saws

- Inlay saws, dowel saws, slotting saw

- Hacksaws

- Fret Saws & Accessories

- One-man crosscut saws and two-man crosscut saws

- Metal saws and blades for metal saws

- Building Saws Yourself

- Musical saws

- Saw Guides & Miter Boxes

- Sharpening Tools for Saw Blades

- Chisel

- Marking & Scribing

- Planes

- Sculpting Tools

- Pliers

- Hammers & Mallets

- Axes, Hatchets & Adzes

- Crowbar, Pry Bar & Nail Puller

- Drawknife

- Assembly tools

- Woodturning Tools

- Clamps

- Fittings

- Safety knives, cutters

- Rasps

- Files

- Miscellaneous

- Promotion

- Drilling & Milling

- Machine Accessories

- Workshop

- Sharpening & Grinding

- Surfaces

- Measuring & Testing

- Household & Garden

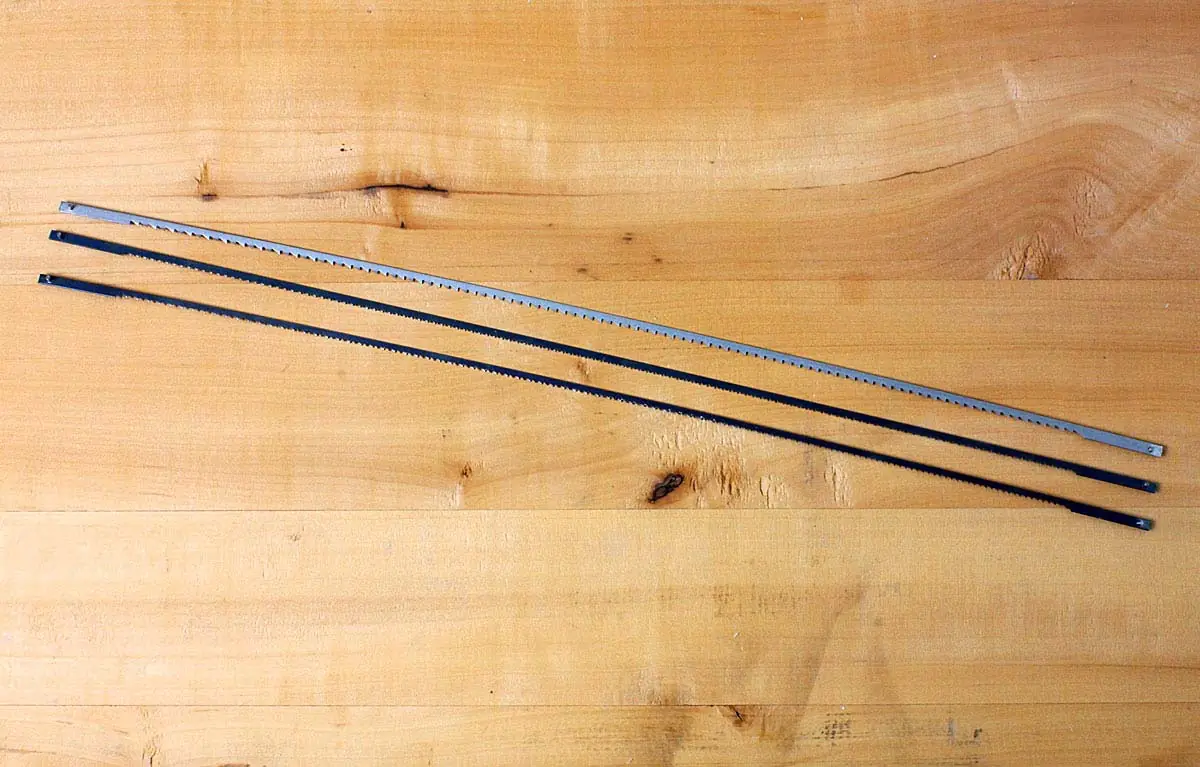

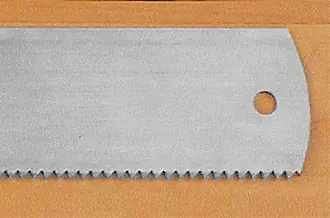

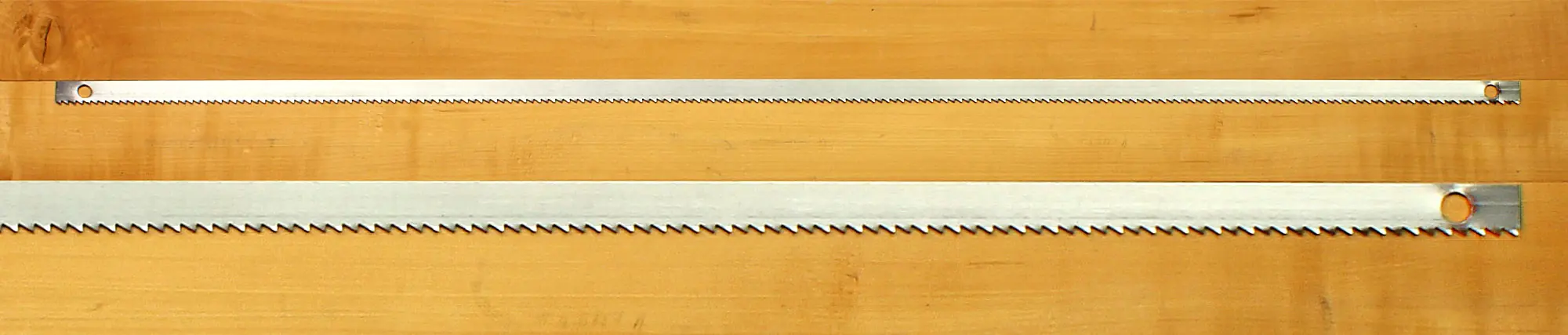

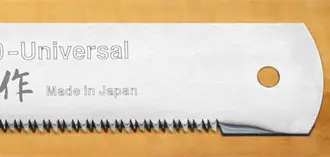

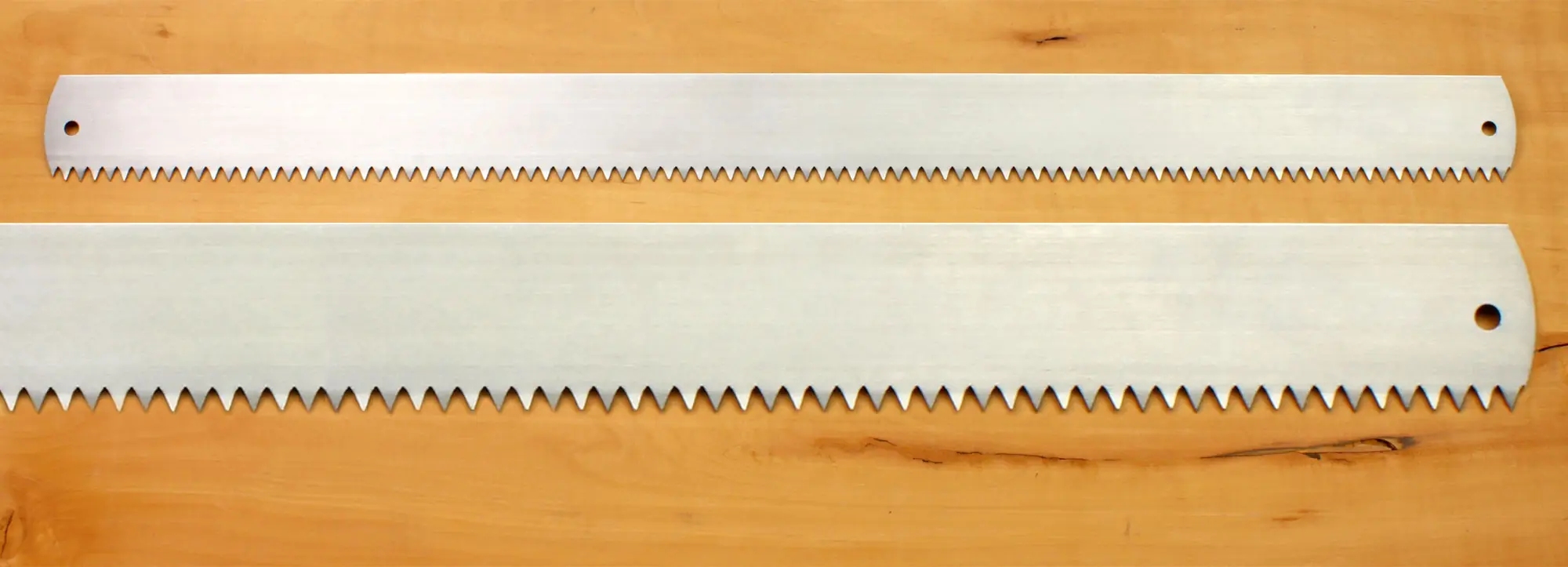

Frame Saws

The wooden construction of the frame saw, also known as a tension saw, consists of two vertical posts (saw arms) and a saw bridge, arranged in an H-shape. Figuratively speaking, the saw blade is located between the two legs of the upright and wide „H”, and the tensioning device is located between its outstretched arms. Because the blade is tensioned, it can be made significantly thinner than, for example, the blade of a handsaw. Traditionally, tensioning was done with a hemp cord, but frame saws manufactured today are tensioned either with a twisted wire or a threaded rod.

The frame saw is universally applicable: for crosscutting, edging, ripping, and tenoning. Crosscutting refers to cutting across the grain to shorten a board. Edging refers to the removal of the tree edge of the board, with the cut running along the grain. Ripping is the longitudinal cutting of tenons for wood joints, and tenoning is the subsequent cut across the grain to shape the tenon. Depending on the task, the saw blades differ: For cuts along the grain, a ripping saw blade with a relatively coarse, filed-to-cut tooth pattern is used; for cuts across the grain, a slightly finer blade with a tooth pattern weakly filed to cut is used. Additionally, the scroll saw is worth mentioning. Scroll saws have a small cross-section of the saw blade and are therefore suitable for curved cuts. A major advantage of the frame saw is the length of the saw blade, which allows for swift work.

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany