- Tools

- Drilling & Milling

- Machine Accessories

- Workshop

- Sharpening & Grinding

- Surfaces

- Measuring & Testing

- Household & Garden

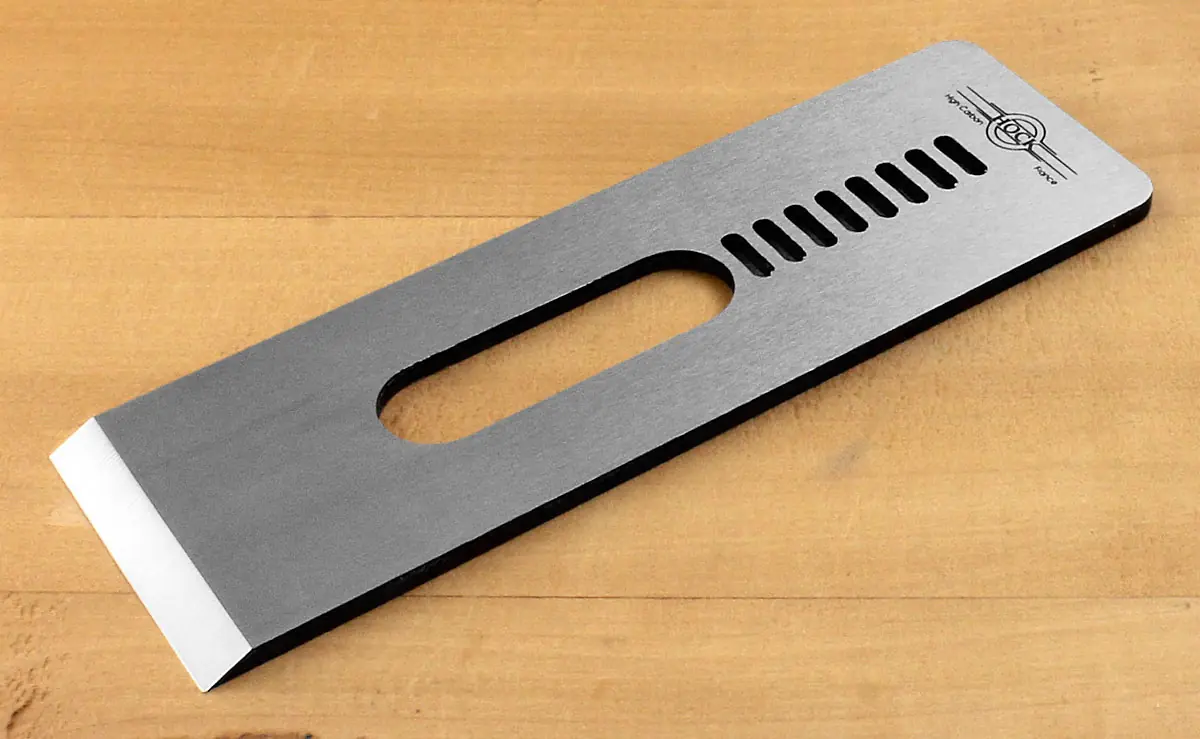

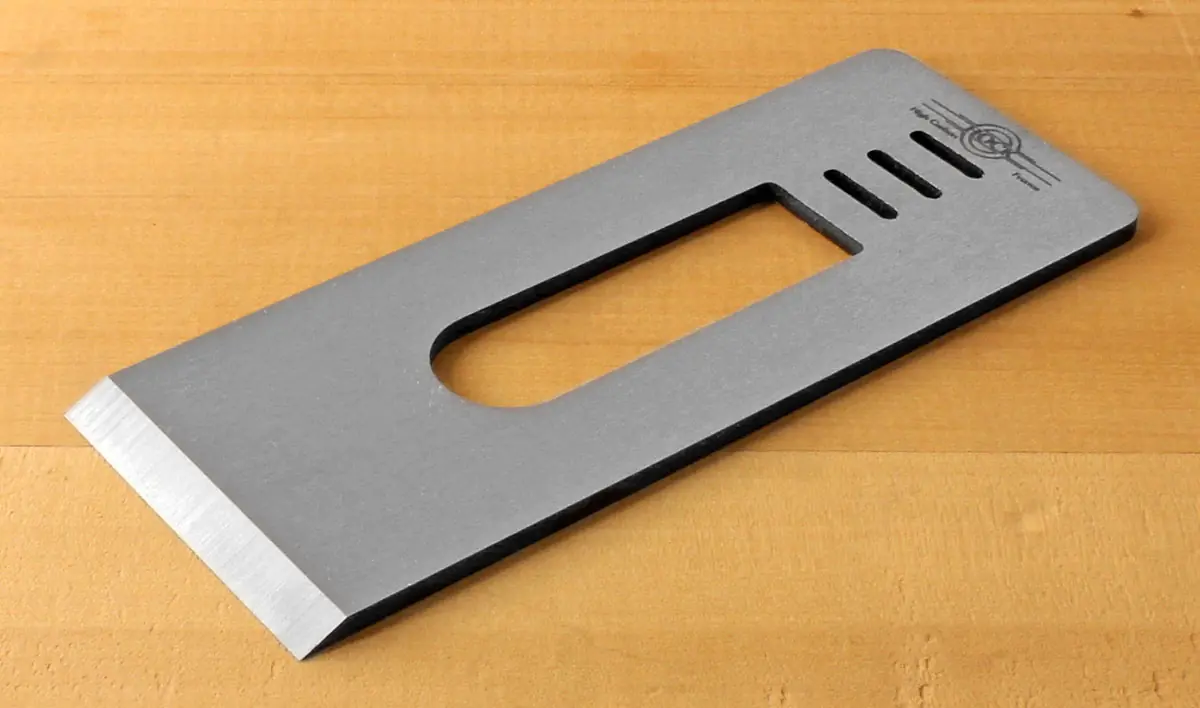

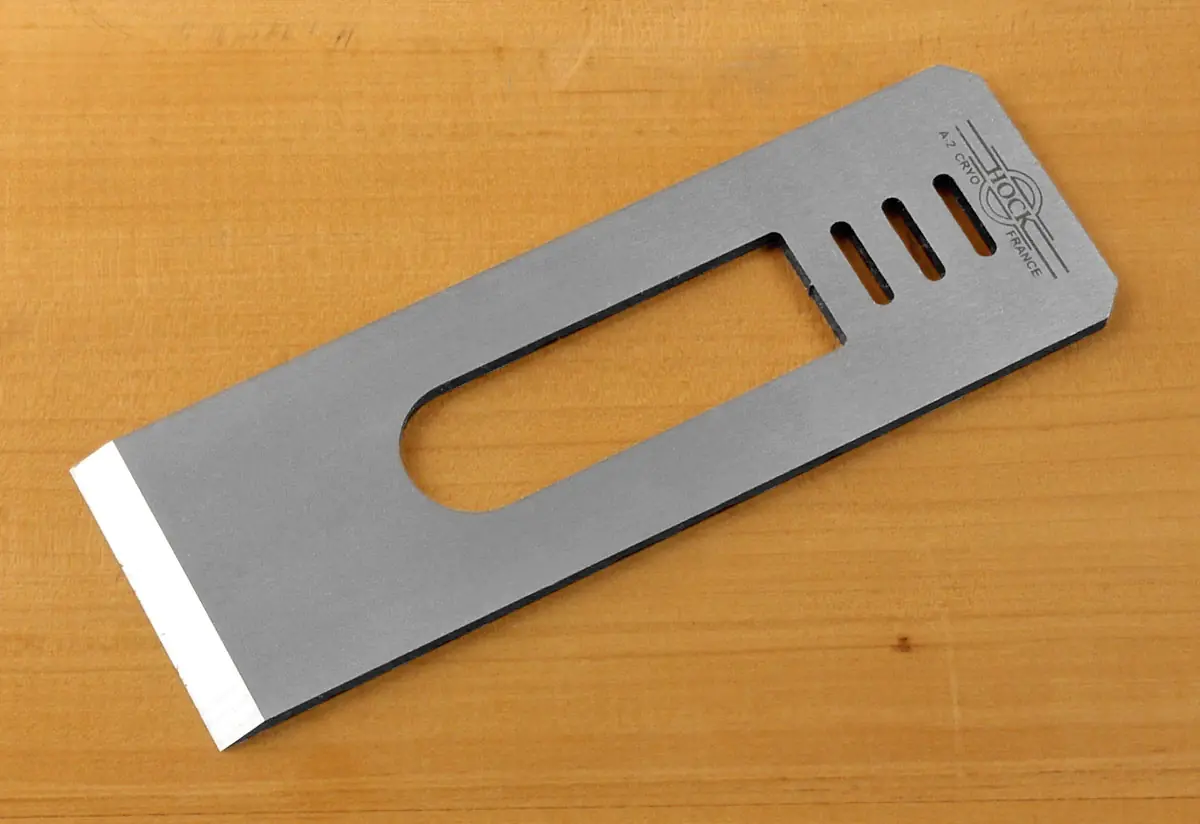

Three characteristics are essential for steel used in cutting hand tools: long edge retention, good sharpenability, and resistance to corrosion. However, from a manufacturing perspective, only two of these properties can be achieved. At HOCK TOOLS, we believe that for woodworkers, resistance to corrosion is the least important property. What is important is an edge that remains sharp for a long time and, when it becomes dull, is easy to sharpen.

The carbon content in steel determines its ability to be hardened through heat treatment. The hardness of the steel determines its ability to maintain the sharpness of the edge even under hard use and to delay wear, meaning dulling, for as long as possible. The harder the steel, the longer the edge stays sharp. However, brittleness also increases with hardness. Tempering the steel at moderate temperatures after hardening reduces this brittleness but also the hardness and wear resistance. The maker of a plane iron must find the balance between these various mutually exclusive properties. Our plane irons are hardened to a Rockwell hardness of 62 HRC, which guarantees good edge retention. They are harder than usual replacement blades but not as hard and brittle as Japanese irons.

„Tool steel” refers to a steel that must be very „clean.” The proportion of alloying elements must not exceed certain values. Vanadium, tungsten, and molybdenum are often added to tool steel to increase its resistance to softening under heat conditions, such as in fast-running tools (high-speed steel). Chromium is added in significant amounts to make the steel stainless. High-speed steels are required for rotating metalworking tools, and stainless steels often serve to simply and inexpensively prevent rust during production, transport, and storage. High-speed steels, stainless steels, or „chrome-vanadium” steels can maintain an edge for a long time in woodworking tools, provided the correct heat treatment process was followed during manufacturing. However, due to the large hard carbon particles that form during the hardening of such steels, they are extremely difficult to sharpen, and the blade can never be honed as sharp as with pure carbon steel. The carbon steel we use (0.95% carbon content) allows for achieving the finest and sharpest edge possible. The proportion of chromium and vanadium additives is below 0.5%, which allows for quick and clean honing with traditional techniques. A carbon steel edge lasts longer and is easier to restore than any other steel. I guarantee it.

Translated from English to German by Dieter Schmid.

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available in 2 days, delivery time 1-3 businessdays within Germany

Available in 183 days, delivery time 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany

Available, delivery time: 1-3 businessdays within Germany