February 13, 2025

Instructions - how to use our Tools

Small Block Plane by Veritas

The inner iron position (within the sole) allows the sole of the plane to bridge recesses, providing more stability, especially when working on narrow workpieces.

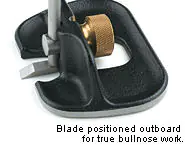

The iron can also be placed outside the sole. With this setting, you have the option to work into corners.

Even when the iron is still outside the workpiece, the sole is already resting on it. As a versatile tool for fine work, especially on narrow workpieces or in confined spaces, this block plane is an indispensable tool for any task that requires small recesses, grooves, and notches.

The ergonomically shaped plane body made of ductile cast iron is precisely manufactured and features a finely ground sole. The plane is 82 mm (3-1/4 inches) wide, 57 mm (2-1/4 inches) long, and has a 6.35 mm (1/4 inch) wide iron made of carbon steel. It weighs 200 g (7 oz.).

The sole of the plane is designed to completely enclose the iron in the inner position. This allows a large part of the sole to contact the workpiece, achieving maximum guidance, even when starting from the outside or reaching the end of the workpiece.

The iron can also be placed outside the sole. With this setting, you have the option to work into corners.

Even when the iron is still outside the workpiece, the sole is already resting on it. As a versatile tool for fine work, especially on narrow workpieces or in confined spaces, this block plane is an indispensable tool for any task that requires small recesses, grooves, and notches.

The ergonomically shaped plane body made of ductile cast iron is precisely manufactured and features a finely ground sole. The plane is 82 mm (3-1/4 inches) wide, 57 mm (2-1/4 inches) long, and has a 6.35 mm (1/4 inch) wide iron made of carbon steel. It weighs 200 g (7 oz.).

The sole of the plane is designed to completely enclose the iron in the inner position. This allows a large part of the sole to contact the workpiece, achieving maximum guidance, even when starting from the outside or reaching the end of the workpiece.

At first glance, a pull plane or working with it may seem strange. Why should one work wood with the pull blade at all? Why this negative angle of the iron? This plane reveals itself upon a closer look at the way it operates. The cutting geometry of the edge with a burr of the pull plane is not very different from the cutting geometry of a bench plane with properly set iron.

Although the edge with a burr works similarly to a plane, the cutting is more like that of a smoothing plane with a steep iron, that is, 55° or 60°, rather than with a plane that has a cutting angle of 45°. This means that the shavings fold over much faster, thereby avoiding tear-out on the planed surface. This is particularly noticeable with wood that has a difficult grain pattern.

The iron of this pull plane is sharpened essentially like a pull blade that is used freehand.

Left: Cross-section of the pull plane

Right: Cross-section of a smoothing plane with chip breaker

Although the edge with a burr works similarly to a plane, the cutting is more like that of a smoothing plane with a steep iron, that is, 55° or 60°, rather than with a plane that has a cutting angle of 45°. This means that the shavings fold over much faster, thereby avoiding tear-out on the planed surface. This is particularly noticeable with wood that has a difficult grain pattern.

The iron of this pull plane is sharpened essentially like a pull blade that is used freehand.

Left: Cross-section of the pull plane

Right: Cross-section of a smoothing plane with chip breaker

Image: inner iron position

The iron can be mounted both inside the sole for standard applications and outside the sole for work into corners. The clamping screw is located on the back of the iron, so it does not obstruct the view of the cutting edge or the exit of shavings. During the adjustment of the cutting depth, the iron is held in place by the pressure of a spring washer.

The iron can be mounted both inside the sole for standard applications and outside the sole for work into corners. The clamping screw is located on the back of the iron, so it does not obstruct the view of the cutting edge or the exit of shavings. During the adjustment of the cutting depth, the iron is held in place by the pressure of a spring washer.

Image: Iron in the outer position for working into the corners.

Detail: The clamping screw is mounted on the back of the iron, so it does not obstruct the view or the ejection of shavings.