February 25, 2025

Instructions - how to use our Tools

Handcrafted rasps by Liogier

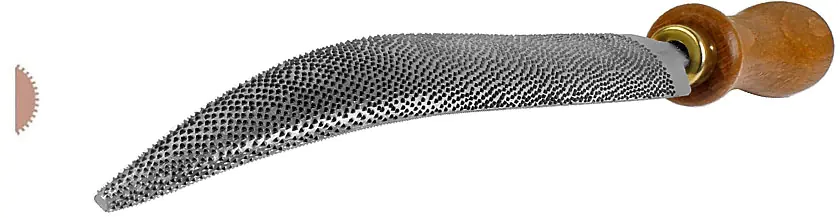

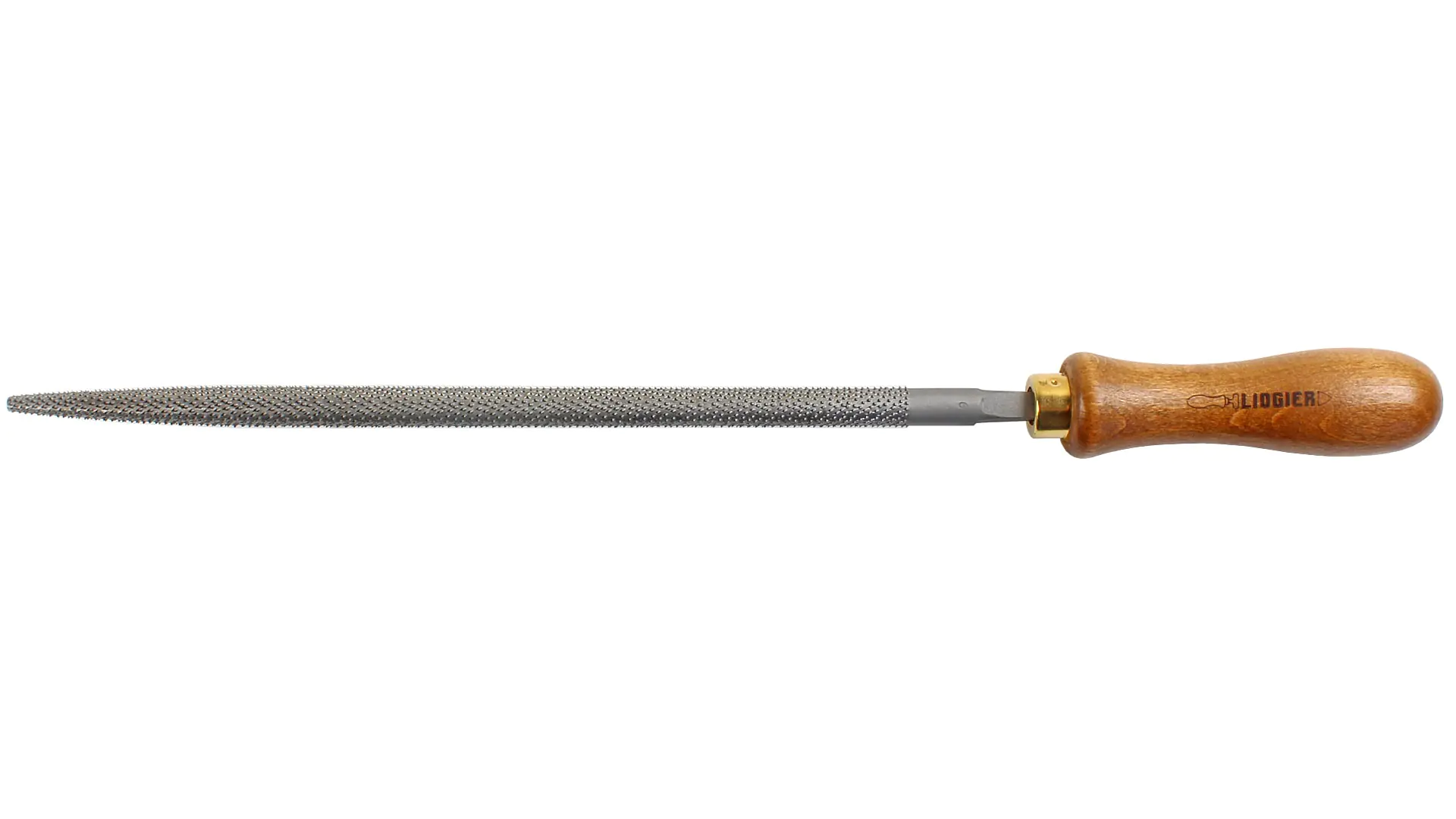

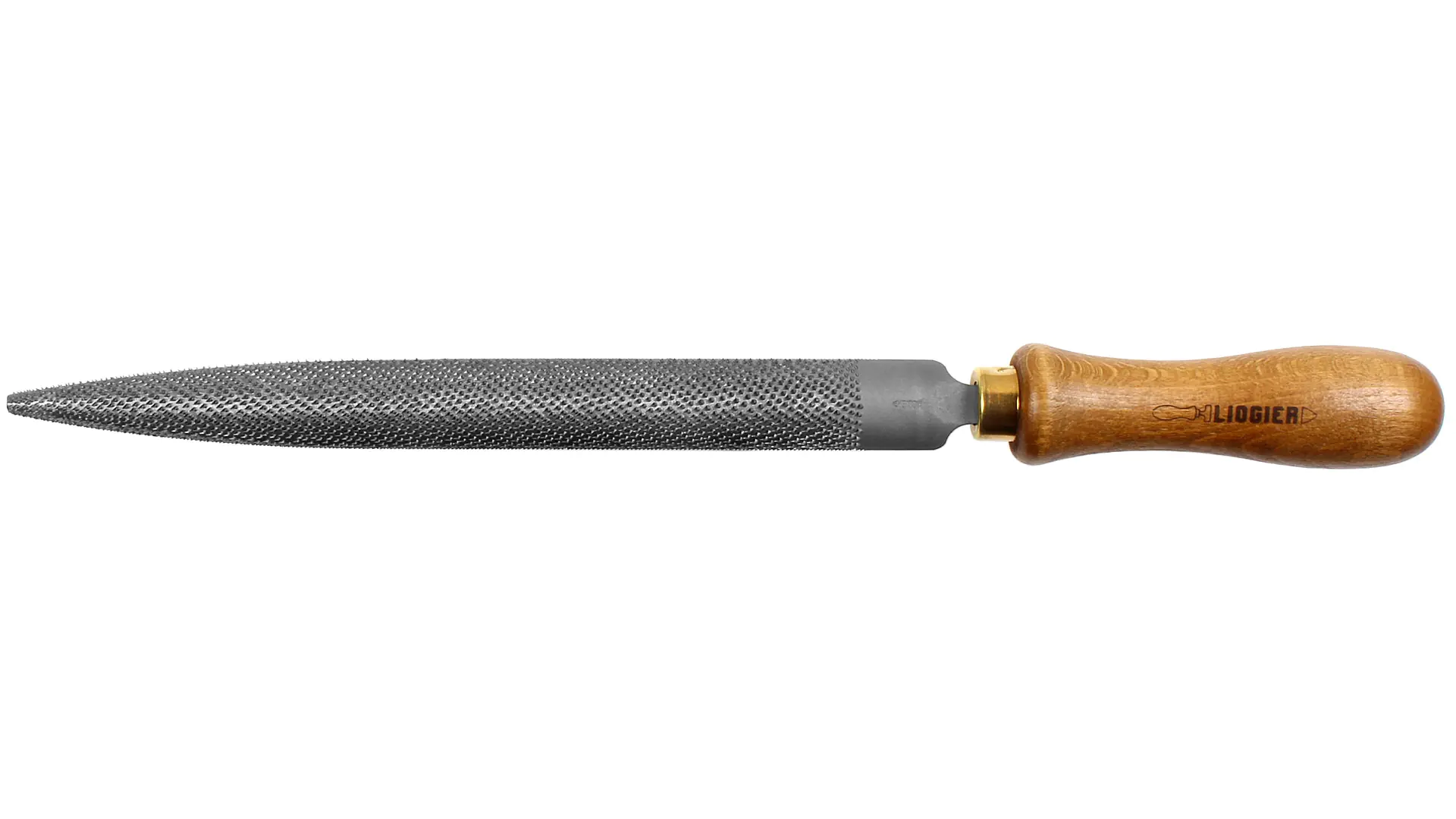

For over 100 years, LIOGIER has been manufacturing high-quality hand-cut rasps in the Auvergne region of France. At times, it was one of the largest manufacturers in Europe for these tools, but virtually unknown outside of France.

Hand-cut rasps differ significantly from machine-cut ones. The material removal is considerably higher with surprisingly good surface quality thanks to the ultra-sharp irregularly cut teeth.

LIOGIER only produces on demand. Therefore, we always have a selection of their rasps in stock to supply you immediately.

The cutting direction of the teeth of these rasps is aligned so that they achieve optimal cutting performance when used right-handed.

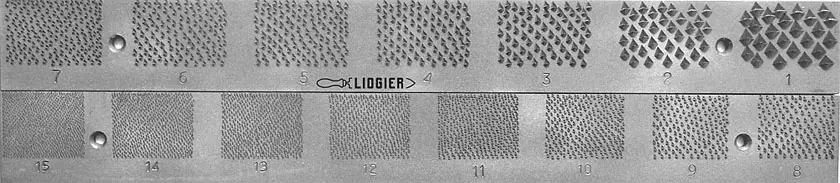

The cuts of the Liogier rasps are numbered from No. 1 to No. 15, with No. 1 being the coarsest and No. 15 the finest. In practice, cuts 4 to 14 are almost exclusively used.

Hand-cut rasps differ significantly from machine-cut ones. The material removal is considerably higher with surprisingly good surface quality thanks to the ultra-sharp irregularly cut teeth.

LIOGIER only produces on demand. Therefore, we always have a selection of their rasps in stock to supply you immediately.

The cutting direction of the teeth of these rasps is aligned so that they achieve optimal cutting performance when used right-handed.

The cuts of the Liogier rasps are numbered from No. 1 to No. 15, with No. 1 being the coarsest and No. 15 the finest. In practice, cuts 4 to 14 are almost exclusively used.

Production of hand-crafted rasps at Liogier

This term refers to a process in which Iwasaki files are dipped into a special liquid heated to 140 °C. This removes the burr from the edges, making them particularly clean and sharp. The specific liquid used is a trade secret. The sculptor files on this page that have undergone this process are accordingly marked.

1) Forging

Am Anfang steht die Auswahl eines besonders feinen Stahls: Liogier verwendet ausschließlich legierten Spezialstahl mit hohem Karbongehalt.

Auf 1250 °C erhitzt wird der Stahlrohling ausreichend formbar um geschmiedet werden zu können.

Dies geschieht durch Gesenkschmieden: Dies ist das einzige Verfahren, durch das die Integrität der inneren Materialstruktur gewährt werden kann und verhindert dass sich Falten oder Lufteinschlüsse im Rohling bilden.

Außerdem garantiert die Kompression des Materials entsprechend der Teileform einen Faserverlauf im Stahl, der ihm eine extreme mechanische Festigkeit verleiht.

Auf 1250 °C erhitzt wird der Stahlrohling ausreichend formbar um geschmiedet werden zu können.

Dies geschieht durch Gesenkschmieden: Dies ist das einzige Verfahren, durch das die Integrität der inneren Materialstruktur gewährt werden kann und verhindert dass sich Falten oder Lufteinschlüsse im Rohling bilden.

Außerdem garantiert die Kompression des Materials entsprechend der Teileform einen Faserverlauf im Stahl, der ihm eine extreme mechanische Festigkeit verleiht.

2) The shaping and preparation of the surface: The goal is the perfect shape

At the beginning is the selection of a particularly fine steel: Liogier exclusively uses alloyed special steel with a high carbon content.

Heated to 1250 °C, the steel blank becomes sufficiently malleable to be forged.

This is done through die forging: This is the only process that can ensure the integrity of the internal material structure and prevents folds or air inclusions from forming in the blank.

Furthermore, the compression of the material according to the shape of the parts guarantees a fiber orientation in the steel that gives it extreme mechanical strength.

Heated to 1250 °C, the steel blank becomes sufficiently malleable to be forged.

This is done through die forging: This is the only process that can ensure the integrity of the internal material structure and prevents folds or air inclusions from forming in the blank.

Furthermore, the compression of the material according to the shape of the parts guarantees a fiber orientation in the steel that gives it extreme mechanical strength.

First, the rasp blank is ground, then it is polished with particularly fine grit, and finally, the finishing takes place. In each step, it solely depends on the skill and experience of the toolmaker to achieve the desired shape.

3) Hand Striking: A Unique Know-How

If, for example, the surface is uneven or not properly polished, this reduces the quality of the rasp, as the teeth cannot achieve the desired sharpness later.

4) Hardening

The blank is clamped on a workbench and the rasp maker looks intently towards the daylight to create one tooth after another.

The training of a rasp maker takes 2 years and to forge a rasp he needs up to 90 minutes.

No incorrect strike is tolerated. The piece must be discarded and a completely new blank must be started. However, it is worth the effort. The result is impressive: an excellent tool that has nothing in common with the rasps and riffler files produced in mass production by machines.

The training of a rasp maker takes 2 years and to forge a rasp he needs up to 90 minutes.

No incorrect strike is tolerated. The piece must be discarded and a completely new blank must be started. However, it is worth the effort. The result is impressive: an excellent tool that has nothing in common with the rasps and riffler files produced in mass production by machines.

Behind this centuries-old process lies another manufacturing secret... the rasp, previously heated to exactly 805°C, is then immersed in a salt bath. This sudden cooling gives the teeth their hardness. The special aspect is the use of a salt bath.