April 2, 2025

Instructions - how to use our Tools

VERITAS Flat Angle Smoothing Plane

The model for this VERITAS low-angle block plane is the traditional wooden block planes of the 19th century.

Until around 1900, the vast majority of block planes produced up to that point had a wooden body and a flat cutting angle. The blades were hand-forged, and these block planes worked wonderfully, but were not easy to adjust. Furthermore, the production of these block planes was expensive.

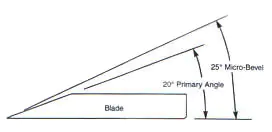

The new VERITAS low-angle block plane has the same low cutting angle as the old block planes (20° bevel with an additional micro-bevel of 25°), however, the cutting depth is adjusted not by changing the blade, but by adjusting the front piece. This method significantly simplifies the notoriously difficult blade adjustment in block planes.

Until around 1900, the vast majority of block planes produced up to that point had a wooden body and a flat cutting angle. The blades were hand-forged, and these block planes worked wonderfully, but were not easy to adjust. Furthermore, the production of these block planes was expensive.

The new VERITAS low-angle block plane has the same low cutting angle as the old block planes (20° bevel with an additional micro-bevel of 25°), however, the cutting depth is adjusted not by changing the blade, but by adjusting the front piece. This method significantly simplifies the notoriously difficult blade adjustment in block planes.

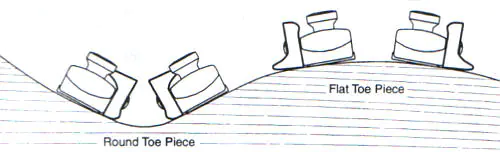

In this setting of the front piece, the hand scraper is used for convex and flat workpieces.

(Blick auf die Sohle)

The front piece rotated 180° allows for easy processing of concave surfaces.

(View of the sole)

Usage Instructions

(View of the sole)

The blade is secured with 2 machine screws, whose specially shaped heads pull the blade into the correct position when the two knurled screws are tightened. The blade can be moved forward or backward to adjust the mouth width. The adjustable front piece determines the shaving thickness.

The aluminum plane body is powder-coated. This hand plane weighs approximately 170 g, and the 3 mm thick blade is made of A2 steel, which is known to hold its sharpness longer than regular tool steel.

The ease of working and the ergonomic shape also allow less experienced users to work much more precisely than what is possible with today's standard hand planes. A very nice tool with classic origins!

The blade is secured with 2 machine screws, whose specially shaped heads pull the blade into the correct position when the two knurled screws are tightened. The blade can be moved forward or backward to adjust the mouth width. The adjustable front piece determines the shaving thickness.

The aluminum plane body is powder-coated. This hand plane weighs approximately 170 g, and the 3 mm thick blade is made of A2 steel, which is known to hold its sharpness longer than regular tool steel.

The ease of working and the ergonomic shape also allow less experienced users to work much more precisely than what is possible with today's standard hand planes. A very nice tool with classic origins!

The VERITAS flat angle scraper has the bevel of the blade like the traditional scrapers above.

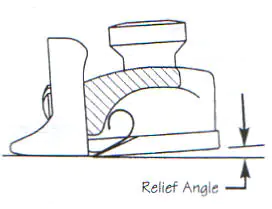

Hold the scraper with both hands. The blade on every scraper must extend beyond the sole in order to cut. Since in this case the blade and sole are identical, the scraper must be tilted slightly forward to achieve this effect. As the correct angle requires some practice and feel, the front piece of this scraper is already shaped with a slight angle to guide you into the correct posture almost automatically.

You can pull or push this scraper. Both are allowed and help you to always work with the wood grain by changing the direction accordingly. With complicated shapes, the working direction often needs to be changed; simply turn the scraper around and work pulling or pushing as you need.

The cutting depth is determined by the position of the front piece. Raised, you achieve thick shavings; lowered, thin shavings. However, note: this scraper is made for fine work and thus rather thin shavings and not for quick material removal like a drawknife.

The iron itself can be adjusted so that the mouth between the blade and the front piece is larger or smaller as needed. However, it should always be as small as possible. A tight mouth pushes the wood fibers down in front of the blade, just before they are cut. This prevents breakouts and splintering of the wood, giving you a clean surface. In other words: The shaving should only be separated from the wood piece when the blade cuts it off. If the mouth of the scraper is too large, meaning the wood is not pushed down close to the blade, the wood will break due to the wedge effect of the iron already a millimeter or more before the blade. The separation of the shaving will then no longer follow the blade (i.e., no longer your wishes) but the grain of the wood. This leads to breakouts and unclean surfaces.

Hold the scraper with both hands. The blade on every scraper must extend beyond the sole in order to cut. Since in this case the blade and sole are identical, the scraper must be tilted slightly forward to achieve this effect. As the correct angle requires some practice and feel, the front piece of this scraper is already shaped with a slight angle to guide you into the correct posture almost automatically.

You can pull or push this scraper. Both are allowed and help you to always work with the wood grain by changing the direction accordingly. With complicated shapes, the working direction often needs to be changed; simply turn the scraper around and work pulling or pushing as you need.

The cutting depth is determined by the position of the front piece. Raised, you achieve thick shavings; lowered, thin shavings. However, note: this scraper is made for fine work and thus rather thin shavings and not for quick material removal like a drawknife.

The iron itself can be adjusted so that the mouth between the blade and the front piece is larger or smaller as needed. However, it should always be as small as possible. A tight mouth pushes the wood fibers down in front of the blade, just before they are cut. This prevents breakouts and splintering of the wood, giving you a clean surface. In other words: The shaving should only be separated from the wood piece when the blade cuts it off. If the mouth of the scraper is too large, meaning the wood is not pushed down close to the blade, the wood will break due to the wedge effect of the iron already a millimeter or more before the blade. The separation of the shaving will then no longer follow the blade (i.e., no longer your wishes) but the grain of the wood. This leads to breakouts and unclean surfaces.