Shapton sharpening stones - Instructions for using the Ha-no-kuromaku series

The soft white plastic insert in the plastic box is only for protection during transport and should be removed. The 12000 grit sharpening stone "Cream" should be soaked in water for about 6 - 10 minutes before use until it has absorbed enough moisture. It should not be left in the water for too long, otherwise the surface will soften, so it should never be stored in a water bath! After drying, it should be stored in the supplied plastic box.

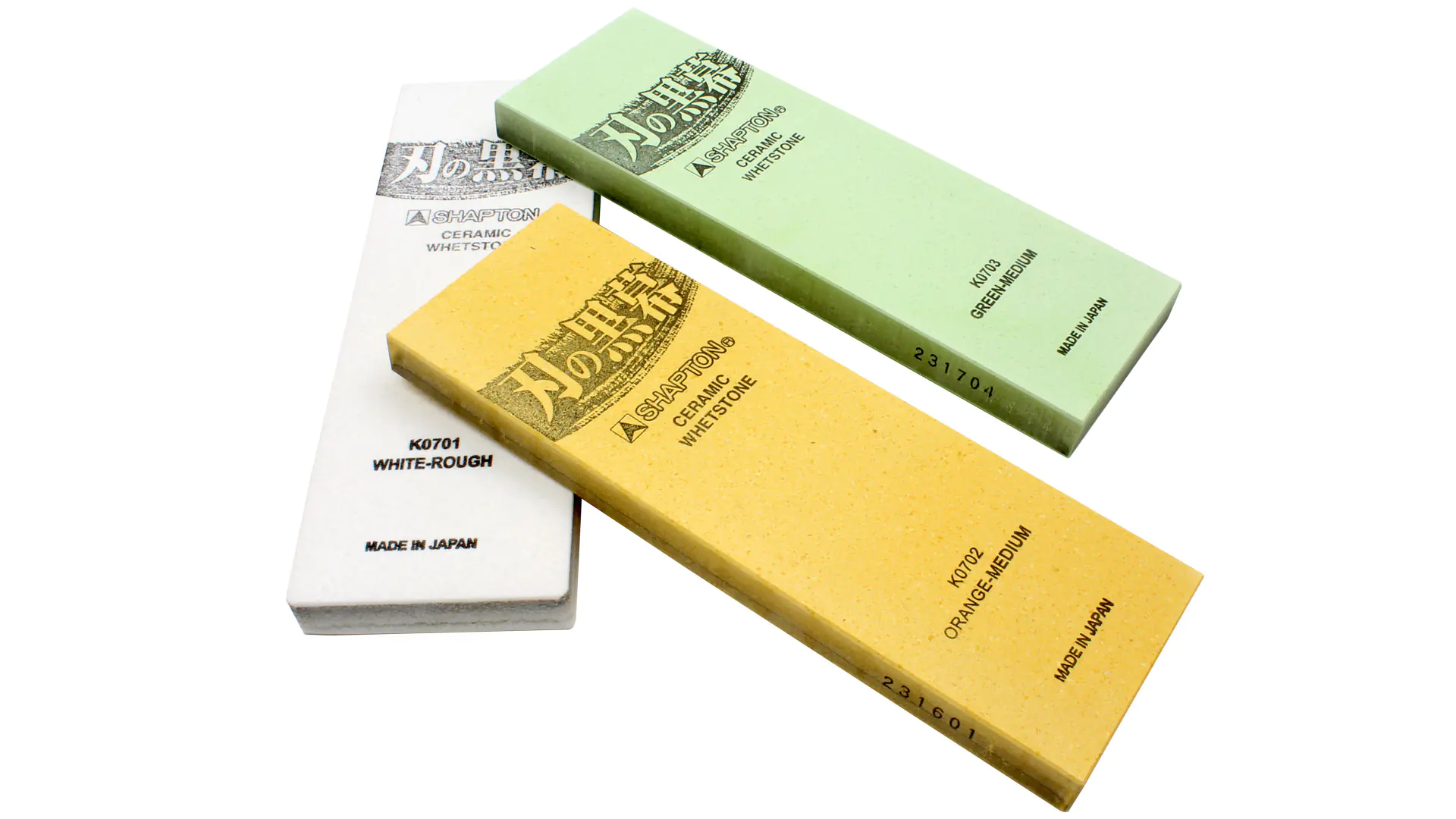

Sharpening with the "Cream" sharpening stone goes quickly when a good base for the subsequent work steps with multiple graduated grits has been created through the initial sharpening. Generally, one should start with grit 1000 (Orange), then gradually use grit 2000 (Green) and grit 5000 (Burgundy), and finally finish with grit 12000 (Cream).

It is advisable to only grind briefly at each stage: this way, the stone is only minimally hollowed out, and the edges can be processed more precisely. This is only possible if one works with a sufficient number of stones. If one works with too few sharpening stones, one has to stay longer on one stone, and the individual stones will thus be hollowed out more quickly.

It is important that the grinding sludge produced in one stage is completely washed away before moving on to the next finer stage: not only from the edge and hands but also from the entire surface of the grinding material, including the handles and under the fingernails. Otherwise, there is a great risk of transferring coarser grinding particles to the next, finer stone.

Perfect sharpening is only possible if the stone is absolutely flat. To achieve flatness, it should be rubbed against another sharpening stone (preferably finer than grit 1000). Both stones should also be soaked in water for 6 - 10 minutes; when dry, they tend to stick to each other, making it difficult to flatten. The second option is to use a sharpening stone dressing block. Also, pay attention to the subsequent thorough cleaning with water.

The sharpening stones from Shapton come in a sturdy plastic box, which also serves for storage. Each grit has its own color. This box can also be used as a sharpening stone holder and stands securely on 4 rubber feet.

Questions and Answers

The body of the plane is made of cast iron and treated with rust protection. With a cloth soaked in test gasoline or turpentine, you can remove this rust protection. Occasionally, you should keep the mechanical parts movable with a few drops of oil and spray the surface with oil when storing for a long time.

If the plane is stored in a humid climate, it should not only be well-oiled but also wrapped in a cloth or oil paper. The oil or oil paper should contain as little silicone as possible, as this will prevent paint from adhering to that spot on the wood surface. You can use the oil we offer for tool maintenance without any concerns. If rust has formed, it is not a disaster; just use a commercially available rust remover.

The shiny brass parts will naturally develop their patina over time. This is normal, but most users are willing to accept it. If you still want it to be shiny again, use a brass polish. The rosewood knobs are lacquered and require no more maintenance than occasional wiping with a dry cloth.

© Veritas.Inc.

Text slightly modified and translated by Dieter Schmid