February 13, 2025

Instructions - how to use our Tools

VERITAS Small Bevel-Up Smooth Plane

This flat angle smoothing plane is 229 mm (9 inches) long, 59 mm (2-5/16 inches) wide, and weighs only 1250 g (2 lb 12 oz). This makes it comparable in size to a No. 3 plane. Since it is smaller and lighter than a full-sized smoothing plane, it is easier to handle and prolonged use is less tiring. Additionally, planing with it requires less effort, as the blade is only 44 mm (1-3/4 inches) wide.

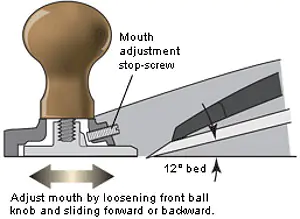

Just like the larger version of this plane, the small flat angle smoothing plane is also useful for finishing surfaces, working on end grain, and chamfering edges. The ground plane body made of ductile cast iron has a bed angle of 12 degrees and an adjustable front piece that is completely surrounded by the sole.

Just like the larger version of this plane, the small flat angle smoothing plane is also useful for finishing surfaces, working on end grain, and chamfering edges. The ground plane body made of ductile cast iron has a bed angle of 12 degrees and an adjustable front piece that is completely surrounded by the sole.

Two holes in the stop allow for the attachment of wood spacers when, for example, a bevel with a defined width is to be created.

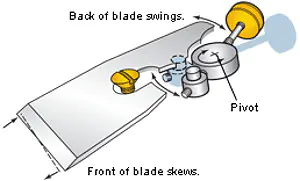

The adjustment mechanism (Norris type) allows the blade to be moved forward and backward sensitively as well as tilted sideways. This makes it easy and precise to set the blade. Limiting screws on both sides of the blade prevent it from shifting while planing. The two handles are made of Bubinga.

Image:

Norris-style adjuster = Blade adjustment (Norris type)

Setscrew = Limiting screws

Image:

Norris-style adjuster = Blade adjustment (Norris type)

Setscrew = Limiting screws

The 3.2 mm (1/8 inch) thick iron has a bevel angle of 25°, resulting in a cutting angle of 37°, which effectively reduces tear-out. The finely ground iron is available in both A2 and O1 steel. For working with complicated woods (irregular grain), there are irons with 38° and 50° bevel angles, also in A2 and O1 steel, as well as a toothed A2 iron.

Image:

Back of blade swings = upper end of the iron swings

Pivot = pivot point

Front of blade skews = cutting edge skews

Image:

Back of blade swings = upper end of the iron swings

Pivot = pivot point

Front of blade skews = cutting edge skews

Jaw width adjustment

Very useful for processing miters in the miter box.

The front piece enclosed by the sole can be adjusted tightly for fine chip removal (minimal fiber tear-out) or opened wider to remove more material.

The movable front piece allows you to set the gap between the iron and the front piece (this is called the mouth) as it makes sense for your work. Typically, the mouth should be tight enough that the shavings just pass through unhindered. The reason for this is that a tight mouth better supports (holds down) the wood directly in front of the iron, thus preventing tear-out that occurs when the shaving continues to tear below the surface of the workpiece.

The movable front piece allows you to set the gap between the iron and the front piece (this is called the mouth) as it makes sense for your work. Typically, the mouth should be tight enough that the shavings just pass through unhindered. The reason for this is that a tight mouth better supports (holds down) the wood directly in front of the iron, thus preventing tear-out that occurs when the shaving continues to tear below the surface of the workpiece.