Frame Saws

The wooden construction of the frame saw, also known as the tension saw, consists of 2 vertical beams (saw arms) and a saw bridge, arranged in an H-shape. Figuratively speaking, the saw blade is located between the two feet of the upright and wide "H," and the tensioning device is between its outstretched arms. Because the blade is tensioned, it can be made significantly thinner than, for example, the blade of a panel saw. Traditionally, tensioning was done with a hemp cord, while today’s frame saws are tensioned either with a twisted wire or a threaded rod.

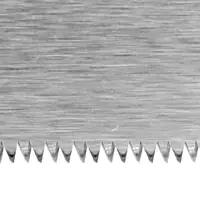

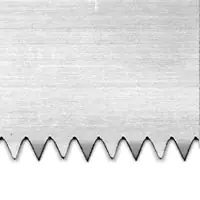

The frame saw is universally applicable: for cross-cutting, edging, slitting, and notching. Cross-cutting refers to the cut across the grain to shorten a board. Edging means removing the bark edge of the board, with the cut going along the grain. Slitting refers to the longitudinal cut for tenons for wood joints, and notching is the subsequent cut across the grain to shape the tenon. Depending on the task, the saw blades differ: for cuts along the grain, the slitting saw blade with relatively coarse, blunt teeth is used, while for cuts across the grain, a slightly finer blade with weakly blunt teeth is used. Furthermore, the coping saw is worth mentioning. Coping saws have a small cross-section of the saw blade and are therefore suitable for curved cuts. A significant advantage of the frame saw is the length of the saw blade, which allows for efficient work.

Increasingly popular is the self-construction of a tension saw or frame saw. This is relatively simple and also very cost-effective to accomplish. Moreover, there are no limits to creativity, especially if one departs from conventional forms a bit. But beware: many have built a very elegant saw with thin, curved saw arms and an even thinner saw bridge, only to find out later that everything bends terribly under tension and the beams were too small for their own hands. So pay attention to sufficient stability and ergonomics when building! For all those who want to try this, we offer not only replacement blades but also saw angles and hemp cord for tensioning. Also, check out our guide for sharpening saw blades (short), or even better: the guide by Friedrich Kollenrott (PDF) (long). In our opinion, the frame saw blades offered on the market are often somewhat over-set and not sufficiently sharpened, and it doesn’t hurt to know how to modify this. The alternative to this is Japanese frame saw blades, optimally sharpened and set, but not resharpenable.

Important: After work is done, frame saws should be relaxed, as the individual parts are subjected to significant stress under tension.