January 27, 2025

Interesting facts

Which Japanese sharpening stone is right for me?

Japanese water stones - both natural and artificial - are known for their rapid sharpening effect - not only for Japanese tools but also for European blades. The loose bond of the abrasive grains causes the dull grains to be washed out very quickly, making room for new sharp grains. These water stones only work with water! Never use oil!

Our large selection delights the connoisseur, as he will surely find the stone that suits his task among the many stones from several renowned manufacturers. We have stones from several manufacturers because each has a different focus, and strengths and weaknesses are widely varied; in other words, for an optimal sharpening set, most woodworkers need stones from multiple manufacturers. If you can commit to the characteristics of certain stones, you can also dedicate yourself to one manufacturer, which can be advantageous in individual cases. There is no one-size-fits-all solution; the stones must fit you and your working style.

On the other hand, a large selection can be confusing, which is why we have put together a small guide here.

First, regarding the different manufacturers:

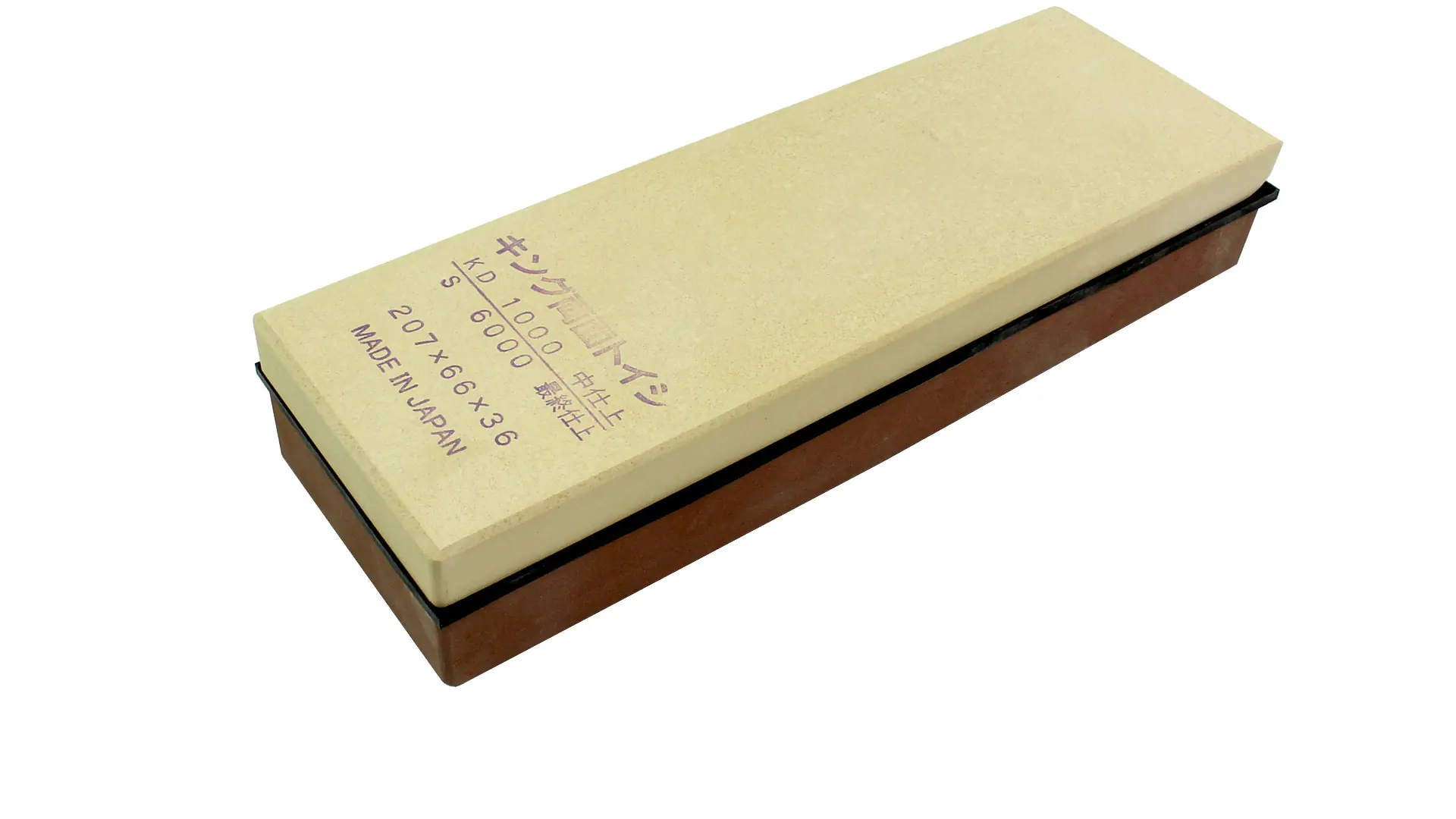

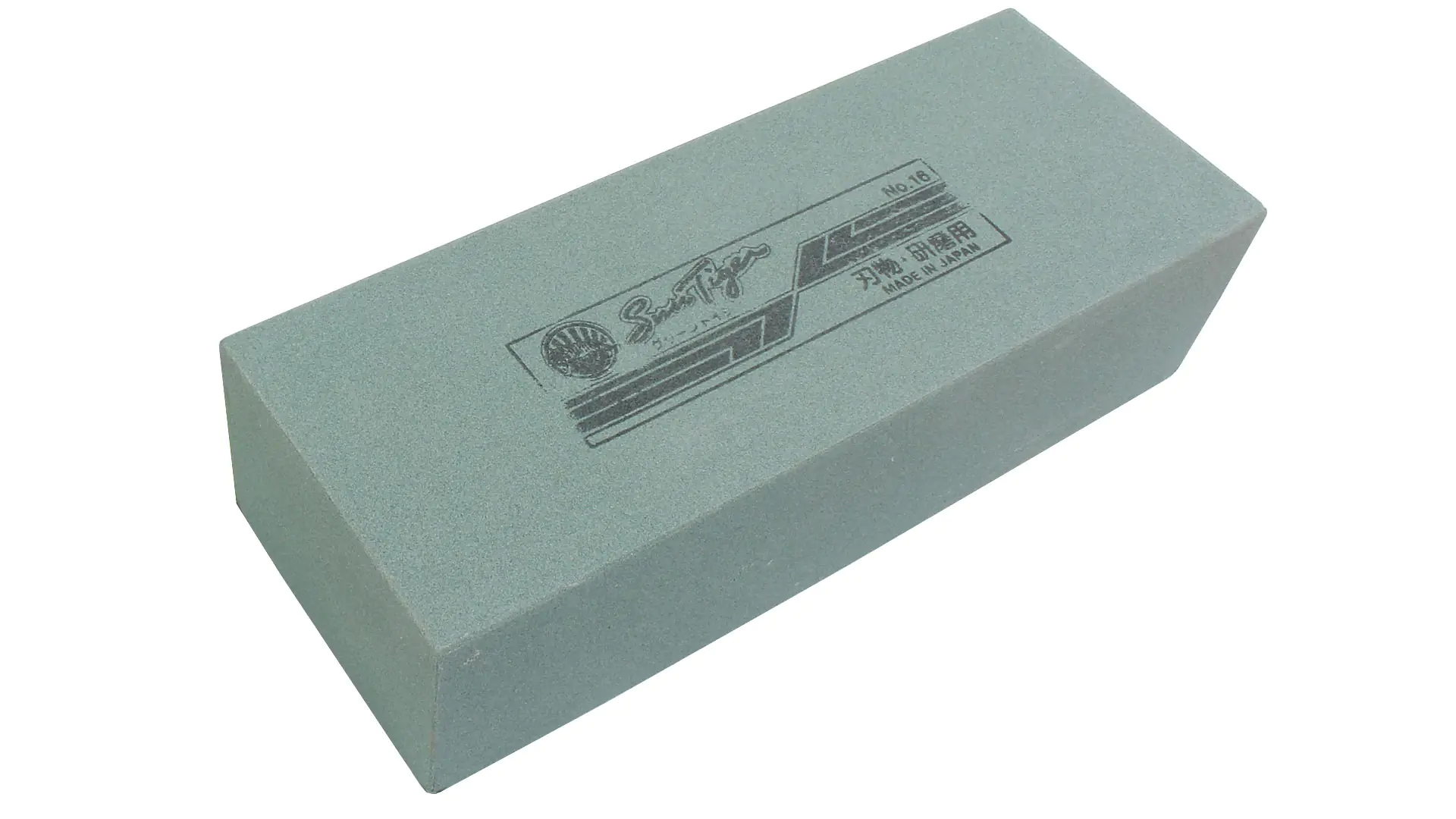

Matsunaga with the brands KING and SUN TIGER is probably the best-known manufacturer in Europe. Its focus is on the production of traditional soft stones that wash out dull grains very quickly during sharpening and release new sharp grains. Such stones need to be flattened more often.

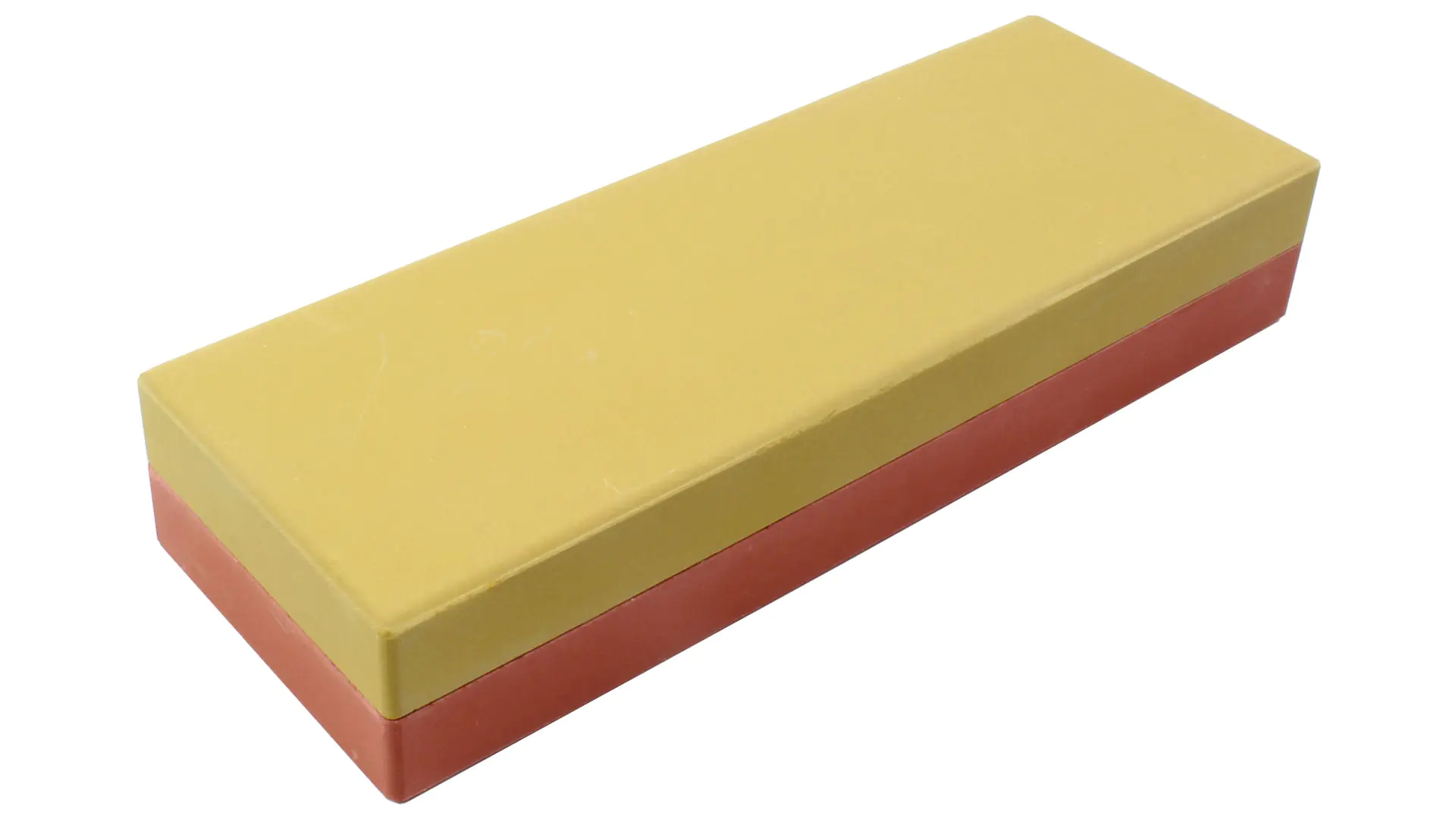

Suehiro with the brands CERAX and SUEHIRO produces stones that are somewhat harder and do not wear out as quickly as the classic Japanese water stones. With the 8000-grit stone, you achieve the sharpest edges and polished mirror surfaces of chisels. Suehiro also produces a small combination stone for those who do not need to sharpen much and want to avoid the expense of a CERAX stone.

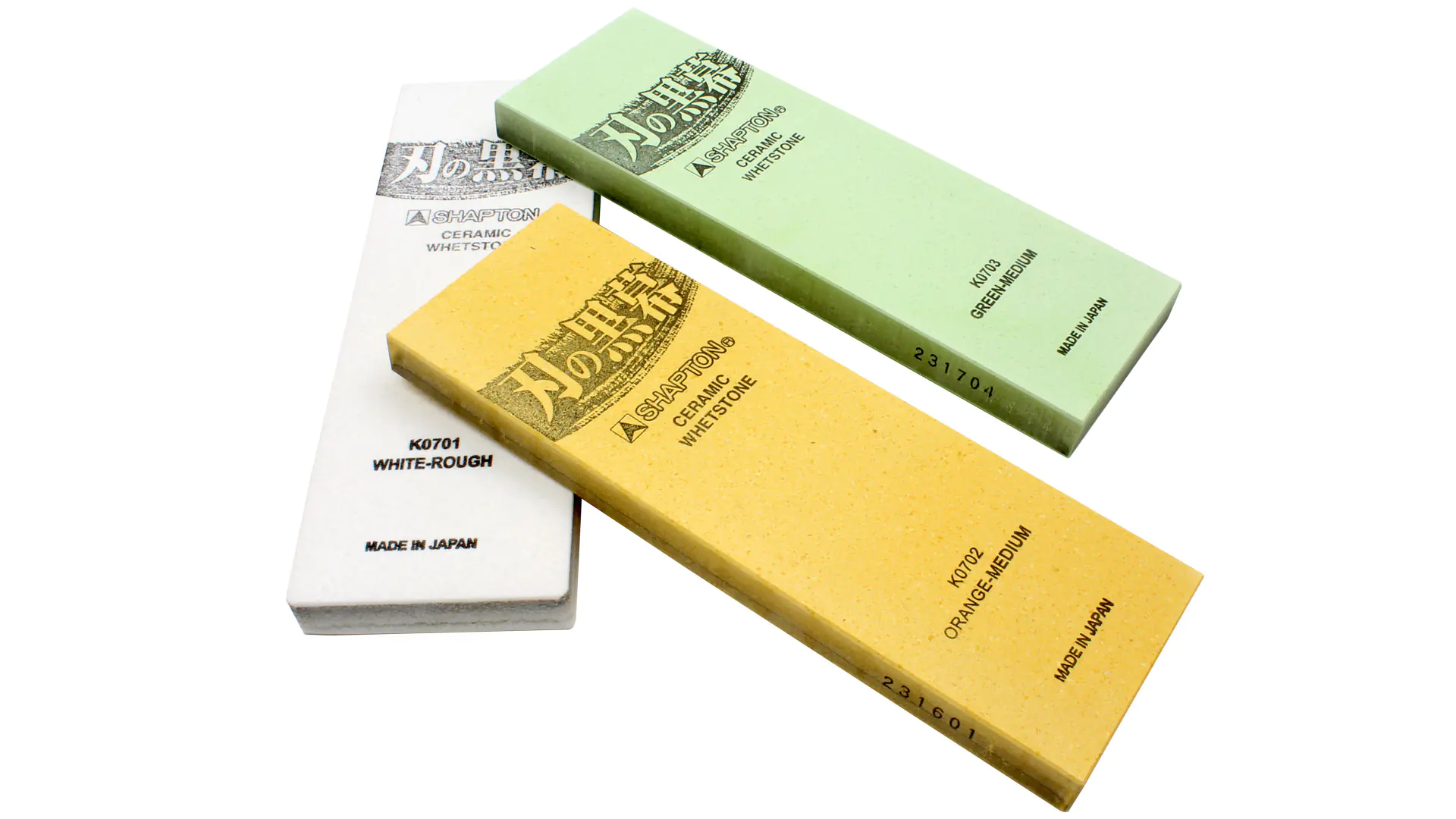

The stones from SHAPTON are probably the hardest Japanese sharpening stones available. These stones remain flat for a long time and are the best choice for those who prioritize maximum material removal while maintaining the shape of the stone. In contrast, a fine Shapton stone does not polish; even with fine honing stones, the result is a fine grinding pattern.

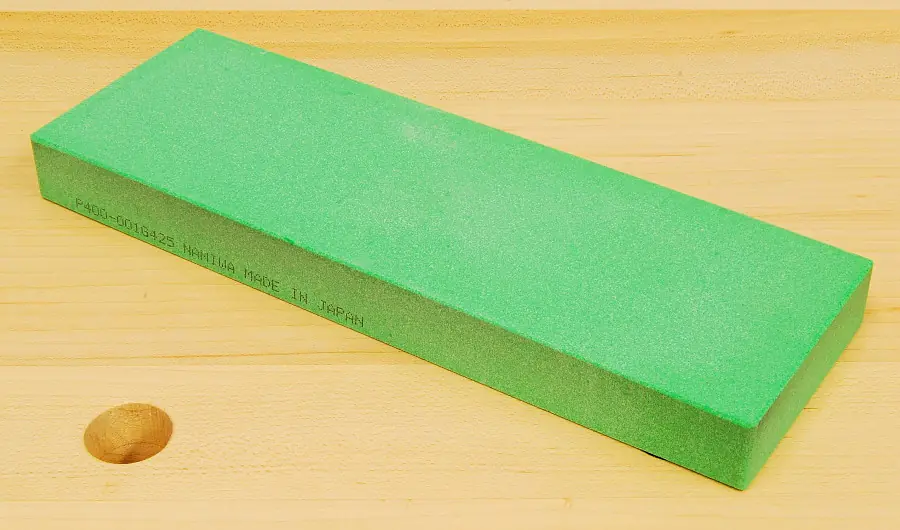

The great strength of NANIWA stones lies primarily in the area of fine stones. No other stone achieves such a high-gloss polished surface.

A sharpening feel almost like that of natural stones is offered by the BESTER sharpening stones from the manufacturer Imanishi from Kyoto. BESTER sharpening stones have a medium hardness, do not require excessive amounts of water, and allow for very quick work.

The sharpening stone manufacturer SIGMA Power Corporation from Tokyo targets users of high-alloy steels such as HSS with its premium line Select II. Even with these stones, the effort to create a sharpening feel similar to that of natural stones is evident. The special manufacturing process is expensive, but the Sigma Select II stones are true steel eaters.

The JUUMA sharpening and honing stones represent a simplified sharpening principle while maintaining the highest possible quality in the offered grits. JUUMA Cobalt Blue stones are made of aluminum oxide and a binding agent. The addition of cobalt serves to reduce stone wear during use and increase sharpening speed. This is particularly noticeable with Blue Steel (blue paper steel, often used in Japanese plane blades and chisels), as the stone grips much better. Cobalt is responsible for the blue color of the stones. JUUMA is our private label. JUUMA sharpening stones are produced in the facility of a renowned Japanese sharpening stone manufacturer.

We recommend Japanese natural sharpening stones only for experienced users who have already extensively familiarized themselves with artificial Japanese sharpening stones. Natural stones do not reveal their qualities to everyone and carry many uncertainties regarding grit, which can never be precisely determined, as well as hardness and suitability for certain steels.

Which stones for which purpose?

For rough work - removing nicks or when the tool is very dull - stones with a grit of 120 to 400 are suitable. We recommend a stone in the grit range of 120 to 240.

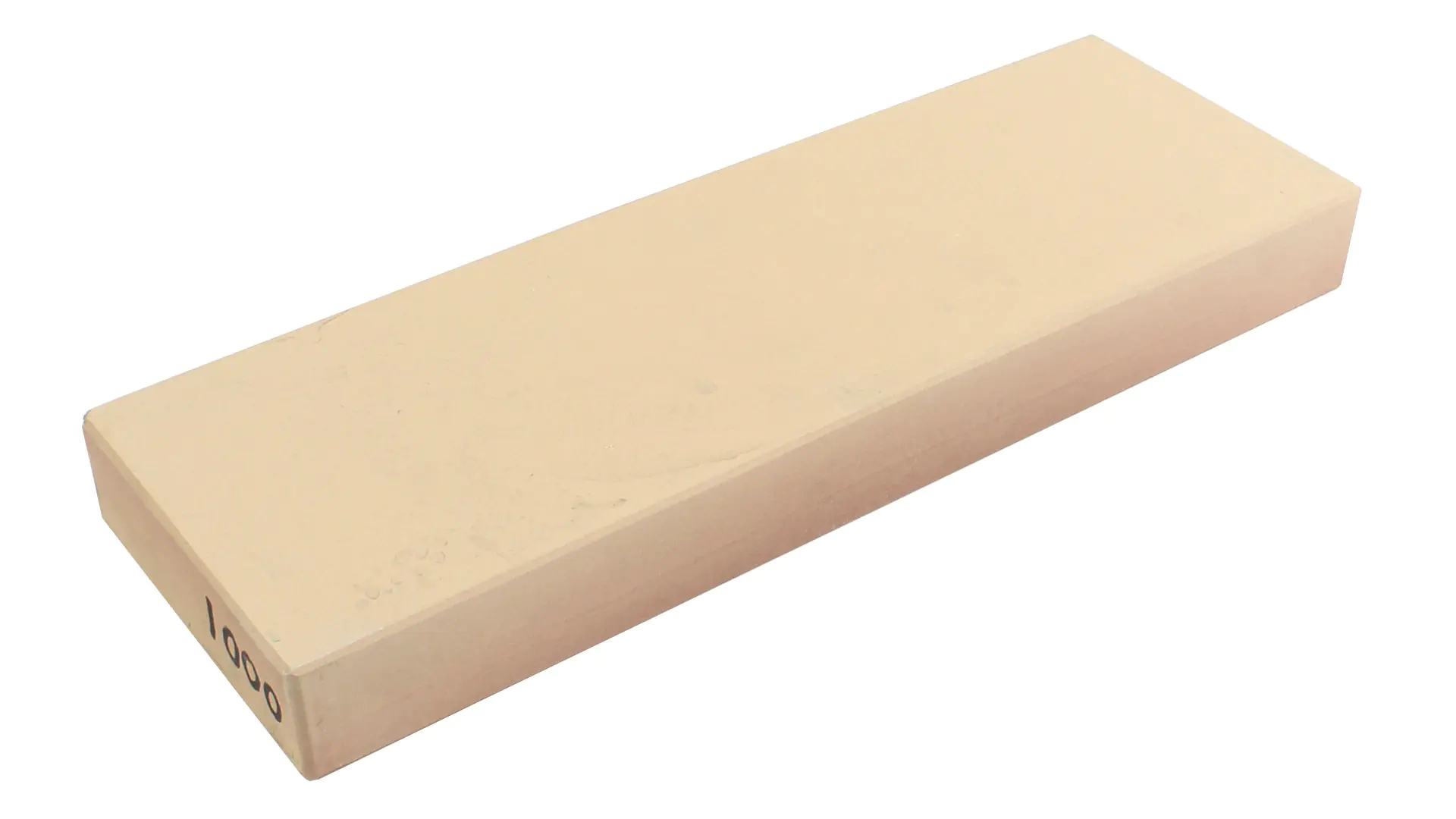

For normal sharpening tasks, stones with a grit of 700 to 2000 can be used. We recommend a stone in the grit range of 700 to 1200.

To remove the fine burr and polish the surfaces, stones from grit 2000 can be used. There are theoretically no upper limits, but stones over a grit of 10000 are unlikely to be of practical use for woodworkers. Interestingly, in Japan, abrasive grains are only standardized up to grit 8000; everything above that is factory standards, and one can only trust the manufacturer.

For those who already have experience in sharpening, we recommend a stone with grit 8000. If you feel uncertain or are a beginner, take a honing stone in the grit range of 3000 to 6000.

As you can see, in principle, you need 3 stones if you want to tackle the most important sharpening tasks. One for roughing, one for sharpening, and one for honing. If you want more comfort, it makes sense to add a 4th or 5th stone to avoid large gaps between the grits.

If you only sharpen occasionally and know that you do not need to grind out a chip, a combination stone is completely sufficient. Which size you choose depends on how much you want to spend. The larger the stone, the faster and more efficiently it works; the small stone is just as good, you just need a bit more time.

How much money do I need to spend on sharpening equipment?

You have many options to assemble the sharpening equipment suitable for you, depending on application and budget. For the 3 stones of ascending grits, you can spend around 50 euros, but you can also spend over 300 euros. It’s best to play around with the prices in the shop a bit. Also, note that the cheaper stones are usually somewhat smaller than the larger ones. Sharpening on large stones is more effective.

Our large selection delights the connoisseur, as he will surely find the stone that suits his task among the many stones from several renowned manufacturers. We have stones from several manufacturers because each has a different focus, and strengths and weaknesses are widely varied; in other words, for an optimal sharpening set, most woodworkers need stones from multiple manufacturers. If you can commit to the characteristics of certain stones, you can also dedicate yourself to one manufacturer, which can be advantageous in individual cases. There is no one-size-fits-all solution; the stones must fit you and your working style.

On the other hand, a large selection can be confusing, which is why we have put together a small guide here.

First, regarding the different manufacturers:

Matsunaga with the brands KING and SUN TIGER is probably the best-known manufacturer in Europe. Its focus is on the production of traditional soft stones that wash out dull grains very quickly during sharpening and release new sharp grains. Such stones need to be flattened more often.

Suehiro with the brands CERAX and SUEHIRO produces stones that are somewhat harder and do not wear out as quickly as the classic Japanese water stones. With the 8000-grit stone, you achieve the sharpest edges and polished mirror surfaces of chisels. Suehiro also produces a small combination stone for those who do not need to sharpen much and want to avoid the expense of a CERAX stone.

The stones from SHAPTON are probably the hardest Japanese sharpening stones available. These stones remain flat for a long time and are the best choice for those who prioritize maximum material removal while maintaining the shape of the stone. In contrast, a fine Shapton stone does not polish; even with fine honing stones, the result is a fine grinding pattern.

The great strength of NANIWA stones lies primarily in the area of fine stones. No other stone achieves such a high-gloss polished surface.

A sharpening feel almost like that of natural stones is offered by the BESTER sharpening stones from the manufacturer Imanishi from Kyoto. BESTER sharpening stones have a medium hardness, do not require excessive amounts of water, and allow for very quick work.

The sharpening stone manufacturer SIGMA Power Corporation from Tokyo targets users of high-alloy steels such as HSS with its premium line Select II. Even with these stones, the effort to create a sharpening feel similar to that of natural stones is evident. The special manufacturing process is expensive, but the Sigma Select II stones are true steel eaters.

The JUUMA sharpening and honing stones represent a simplified sharpening principle while maintaining the highest possible quality in the offered grits. JUUMA Cobalt Blue stones are made of aluminum oxide and a binding agent. The addition of cobalt serves to reduce stone wear during use and increase sharpening speed. This is particularly noticeable with Blue Steel (blue paper steel, often used in Japanese plane blades and chisels), as the stone grips much better. Cobalt is responsible for the blue color of the stones. JUUMA is our private label. JUUMA sharpening stones are produced in the facility of a renowned Japanese sharpening stone manufacturer.

We recommend Japanese natural sharpening stones only for experienced users who have already extensively familiarized themselves with artificial Japanese sharpening stones. Natural stones do not reveal their qualities to everyone and carry many uncertainties regarding grit, which can never be precisely determined, as well as hardness and suitability for certain steels.

Which stones for which purpose?

For rough work - removing nicks or when the tool is very dull - stones with a grit of 120 to 400 are suitable. We recommend a stone in the grit range of 120 to 240.

For normal sharpening tasks, stones with a grit of 700 to 2000 can be used. We recommend a stone in the grit range of 700 to 1200.

To remove the fine burr and polish the surfaces, stones from grit 2000 can be used. There are theoretically no upper limits, but stones over a grit of 10000 are unlikely to be of practical use for woodworkers. Interestingly, in Japan, abrasive grains are only standardized up to grit 8000; everything above that is factory standards, and one can only trust the manufacturer.

For those who already have experience in sharpening, we recommend a stone with grit 8000. If you feel uncertain or are a beginner, take a honing stone in the grit range of 3000 to 6000.

As you can see, in principle, you need 3 stones if you want to tackle the most important sharpening tasks. One for roughing, one for sharpening, and one for honing. If you want more comfort, it makes sense to add a 4th or 5th stone to avoid large gaps between the grits.

If you only sharpen occasionally and know that you do not need to grind out a chip, a combination stone is completely sufficient. Which size you choose depends on how much you want to spend. The larger the stone, the faster and more efficiently it works; the small stone is just as good, you just need a bit more time.

How much money do I need to spend on sharpening equipment?

You have many options to assemble the sharpening equipment suitable for you, depending on application and budget. For the 3 stones of ascending grits, you can spend around 50 euros, but you can also spend over 300 euros. It’s best to play around with the prices in the shop a bit. Also, note that the cheaper stones are usually somewhat smaller than the larger ones. Sharpening on large stones is more effective.