January 24, 2025

Additional information

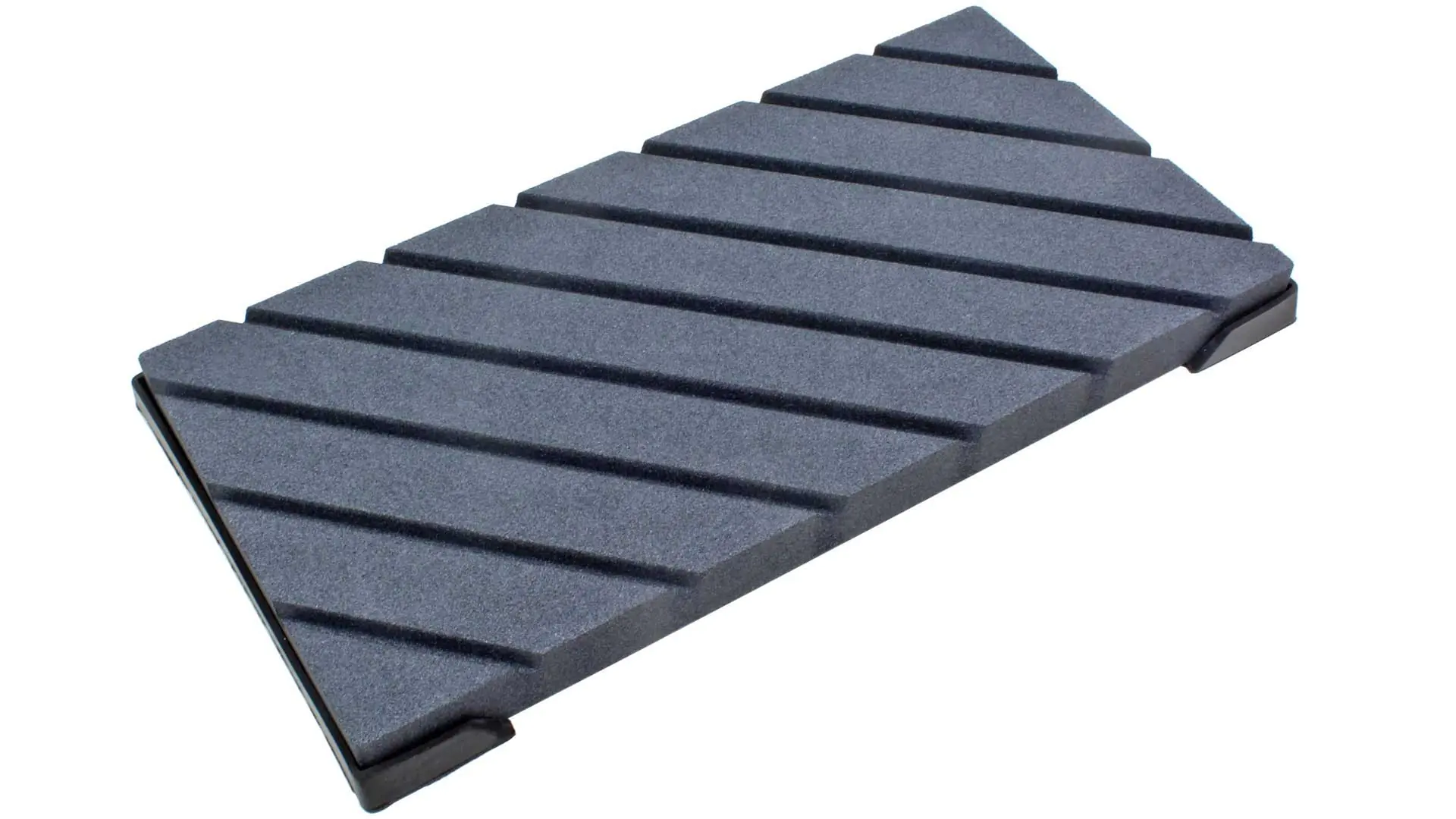

The use of Japanese water stones

Japanese water stones are known for their fast sharpening effect. The loose binding of the abrasive grains causes the dull grains to be washed out very quickly, making room for new sharp grains.

Water stones only work with water! Never use oil! It will render your stone worthless! Under no circumstances should you store Japanese water stones constantly in water, as the surface may soften. Never expose wet stones to temperatures below 0° Celsius, as they can break.

Soak the sharpening stone in water before use - five minutes is usually sufficient, and for very coarse stones, it may take up to 10 minutes. Place the stone on a non-slip surface or clamp it between two wooden wedges. Try to use as much of the stone's surface as possible to delay the inevitable hollow grinding for as long as possible. The grinding sludge should be rinsed off regularly, but it can remain on the stone if you want to achieve a finer sharpening effect with the same stone - ideally just before the end of the sharpening process. However, when switching to a finer stone, the grinding sludge from the previously used coarser stone should be thoroughly washed off to avoid transferring coarse grains.

Choose the stones for the intended purpose. As a guideline, the following can apply:

The sharpening stone must be flat. You will never achieve good results with a worn and hollowed stone. Such a stone must be made flat again, i.e., dressed. Japanese water stones are quick and easy to dress because they are soft and the structure is loose. Therefore, this process may be required more frequently. There are various methods for this.

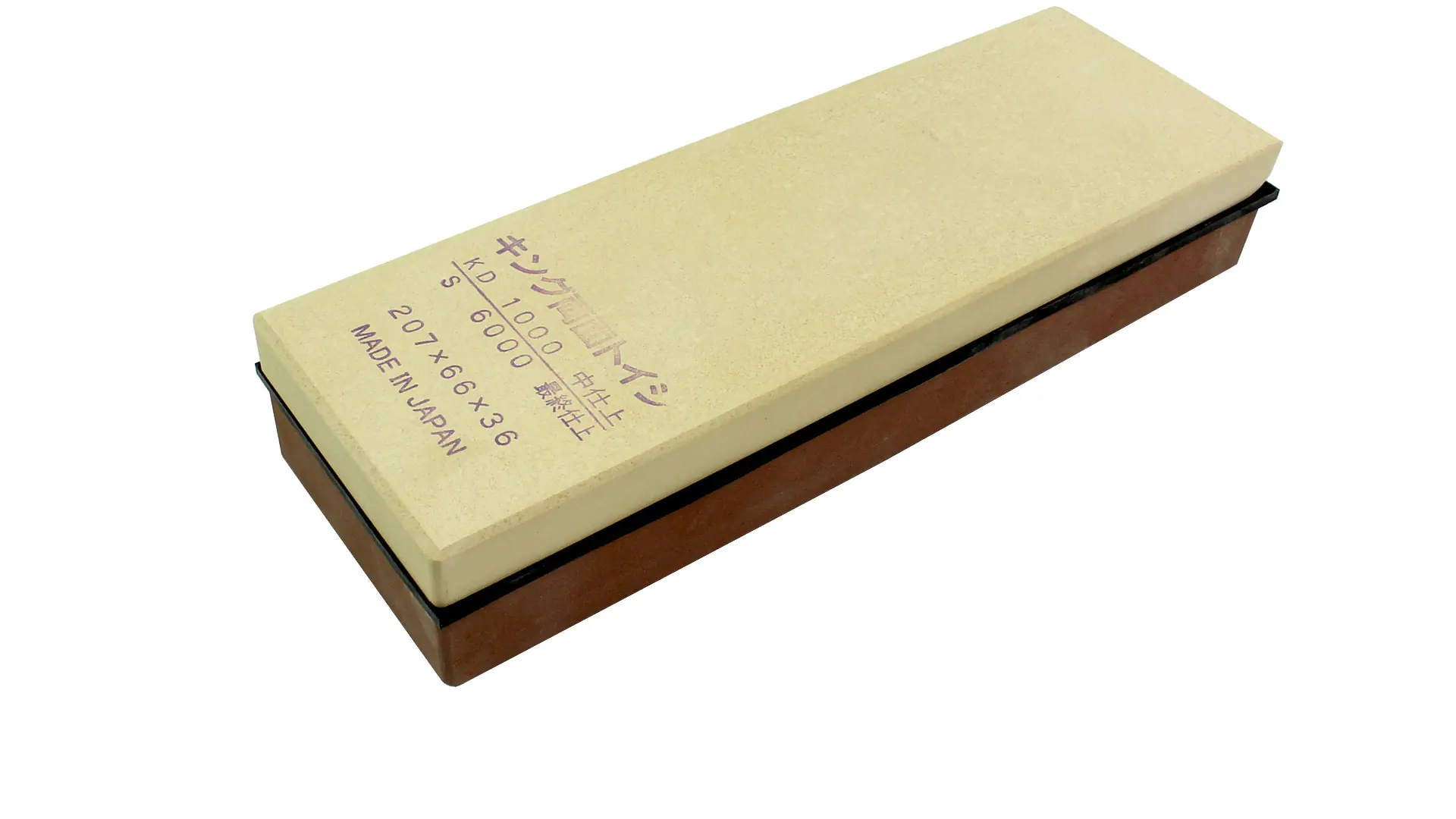

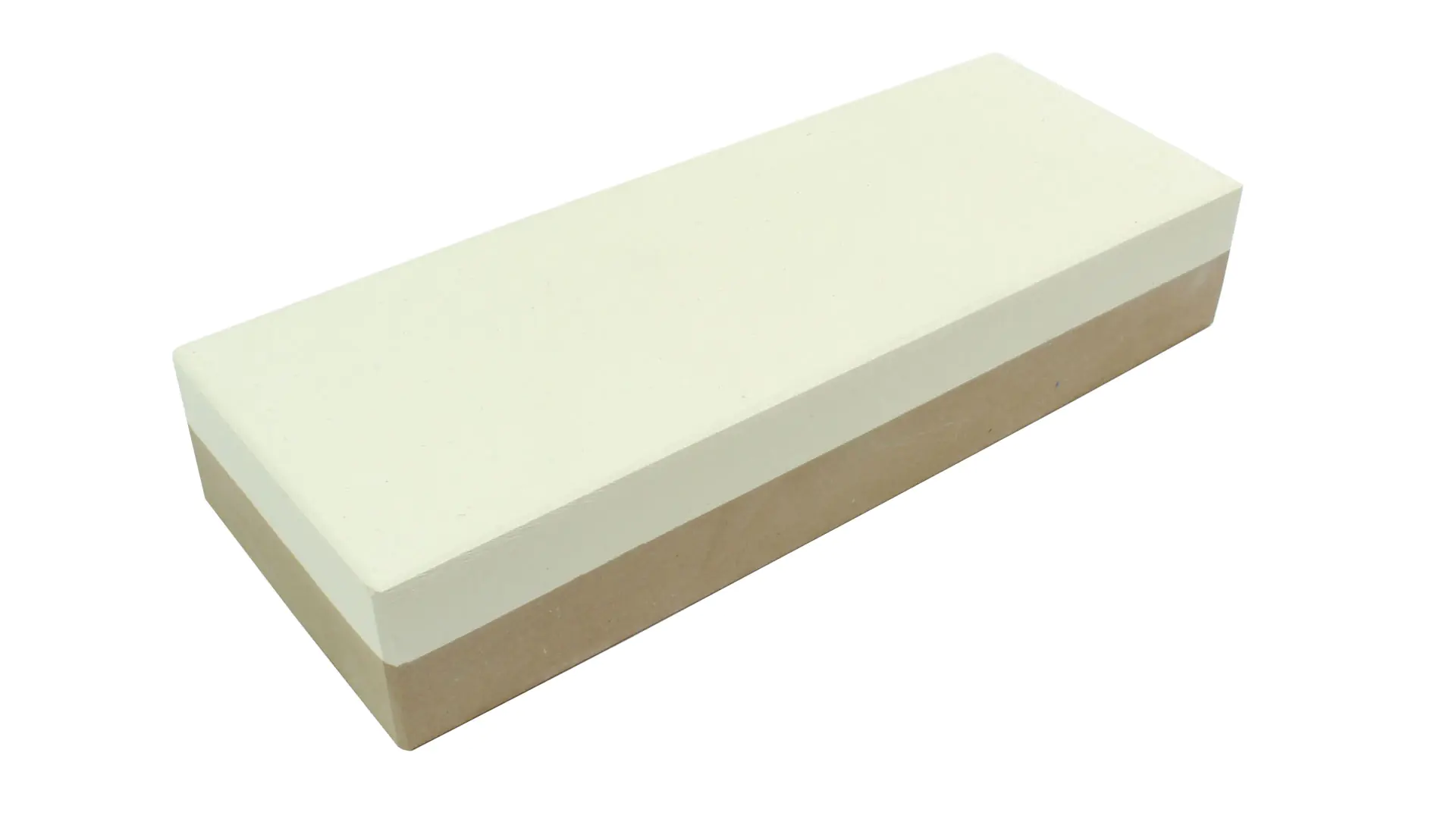

Important note for combination stones: Since Japanese water stones have a very loose binding of the grains, it is only logical that the adhesion of the two stone halves cannot be extremely strong. It may happen that the two stone halves come apart. This is not a reason for complaint! Use a household waterproof adhesive to reattach the two parts or continue using the two halves separately.

Water stones only work with water! Never use oil! It will render your stone worthless! Under no circumstances should you store Japanese water stones constantly in water, as the surface may soften. Never expose wet stones to temperatures below 0° Celsius, as they can break.

Soak the sharpening stone in water before use - five minutes is usually sufficient, and for very coarse stones, it may take up to 10 minutes. Place the stone on a non-slip surface or clamp it between two wooden wedges. Try to use as much of the stone's surface as possible to delay the inevitable hollow grinding for as long as possible. The grinding sludge should be rinsed off regularly, but it can remain on the stone if you want to achieve a finer sharpening effect with the same stone - ideally just before the end of the sharpening process. However, when switching to a finer stone, the grinding sludge from the previously used coarser stone should be thoroughly washed off to avoid transferring coarse grains.

Choose the stones for the intended purpose. As a guideline, the following can apply:

- For coarse work - removing nicks or when the tool is very dull - a stone with a grit of 120 to 400 is recommended.

- For normal sharpening tasks, a stone with a grit of 700 to 2000 is the right choice.

- For honing the fine edge and polishing surfaces, use grit sizes of 3000 to 12000.

The sharpening stone must be flat. You will never achieve good results with a worn and hollowed stone. Such a stone must be made flat again, i.e., dressed. Japanese water stones are quick and easy to dress because they are soft and the structure is loose. Therefore, this process may be required more frequently. There are various methods for this.

- Rub two stones against each other - this is the oldest and most widely used method. The stones should be wet, meaning they should be soaked in water for several minutes beforehand.

- Use a specially made flat sharpening stone dressing block, add some water to its surface, a teaspoon of silicon carbide powder, and then the stone can be worked in circular motions under light pressure.

- The third option is to use waterproof sandpaper, which can be soaked on a glass plate or another flat surface. For heavily hollowed stones, feel free to use 80 or 120 grit, and then finer for improving the surface. You can also add silicon carbide powder, which will double the working speed.

- Afterward, thoroughly clean the stones under running water to avoid transferring coarser grains, which can lead to scratches on the blade surface during sharpening.

Important note for combination stones: Since Japanese water stones have a very loose binding of the grains, it is only logical that the adhesion of the two stone halves cannot be extremely strong. It may happen that the two stone halves come apart. This is not a reason for complaint! Use a household waterproof adhesive to reattach the two parts or continue using the two halves separately.